KGM (konjac glucomannan) blended polymer oil displacement agent and preparation method thereof

A blended polymer and oil displacement agent technology, applied in the field of KGM blended polymer oil displacement agent, to achieve good temperature resistance, improved thermal stability, and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

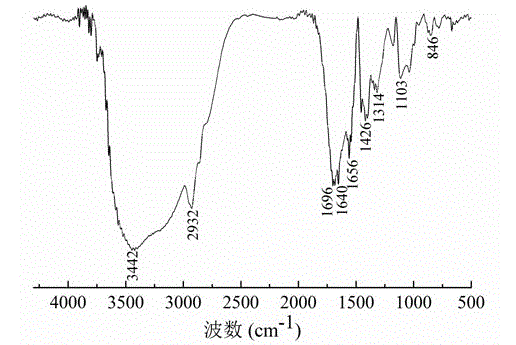

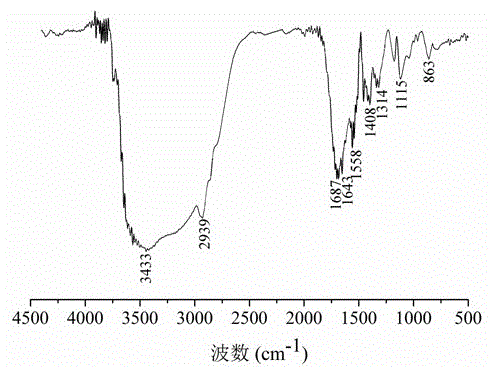

Image

Examples

Embodiment 1

[0053] Embodiment 1: the preparation of NCE monomer

[0054] Add 3g of 2-pyridinecarboxylic acid, 6mL of thionyl chloride and 10mL of dichloromethane in sequence in the reaction flask, heat up to 55°C for 2-6h after the addition, cool down to room temperature, and spin out the unreacted thionyl chloride. Obtain light red solid product 2-pyridine carboxylic acid chloride, yield 98-99.5%; Dilute the 2-pyridine carboxylic acid chloride obtained in the previous step with dry methylene chloride, and slowly add 3.5g diallyl dichloride dropwise under ice bath A mixed solution of amine and 10.9g triethylamine, react at 25°C for 4-6h to stop the reaction after dropping, and the reaction solution is washed with water, washed with alkali, dried, filtered, and distilled under reduced pressure to obtain NCE, a light brown liquid monomer. The yield was 87.8%.

Embodiment 2

[0055] Embodiment 2: the preparation of NCT monomer

[0056] Add 3g of 3-pyridinecarboxylic acid and 6mL of thionyl chloride successively into the reaction flask, heat up to 55°C for 2-6h after the addition, and then cool to room temperature, spin off the unreacted thionyl chloride to obtain the white solid product 3 -Pyridine carboxylic acid chloride, yield 98-99.5%; Dilute the 3-pyridine carboxylic acid chloride obtained in the previous step with dry dichloromethane, slowly add 3.5g diallylamine and 10.9g triethylamine dropwise under ice bath The mixed solution of amines was reacted at 25°C for 4-6 hours to stop the reaction after dropping. The reaction solution was washed with water, washed with alkali, dried, filtered, and distilled under reduced pressure to obtain NCT, a dark yellow liquid monomer, with a yield of 88.2%.

Embodiment 3

[0057] Embodiment 3: the preparation of NCI monomer

[0058] Add 3g of 4-pyridinecarboxylic acid and 6mL of thionyl chloride to the reaction flask in sequence, heat up to 55°C and react for 2-6h after the addition, cool down to room temperature, spin out the unreacted thionyl chloride to obtain the white solid product 4 -Pyridine carboxylic acid chloride, yield 98-99.5%; The 3.4g 4-pyridine carboxylic acid chloride obtained in the previous step was diluted with dry dichloromethane, slowly added dropwise 3.5g diallylamine and 10.9g The mixed solution of triethylamine was reacted at 25°C for 4-6 hours to stop the reaction after dropping. The reaction solution was washed with water, washed with alkali, dried, filtered and distilled under reduced pressure to obtain NCI, a dark red liquid monomer, with a yield of 89.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com