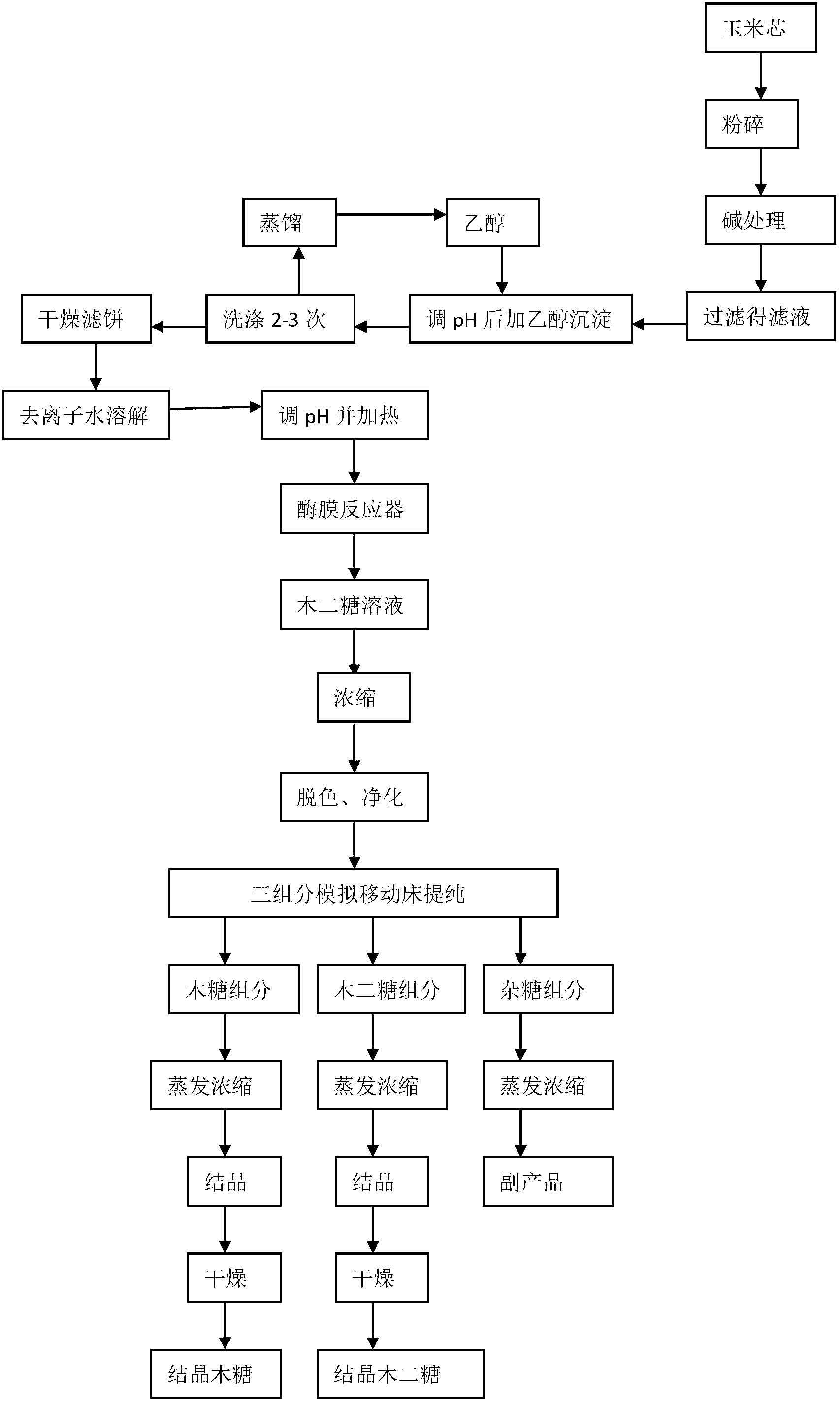

Co-production process for xylobiose and xylose

A production method and technology of xylobiose, applied in disaccharides, sugar derivatives, sugar derivatives, etc., can solve the problems of large production time, high cost, and low purity, and achieve good product quality, low cost, and high yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Grinding the selected corncobs, weighing 100 kg of the crushed corncobs, adding 2mol / L sodium hydroxide solution according to 10 times the weight of the corncobs, treating at 50°C for 10h, and filtering to obtain the dissolved xylan solution, adjust the pH value of the eluate to 5.0-7.0, then add ethanol that is 3 times the volume of the feed solution, and place it at a low temperature of 4°C for 6-12 hours to make the xylan form a flocculent precipitate. After filtering the precipitate, remove the precipitate with a small amount Dissolve in ionic water, then add ethanol with 3 times the volume of the feed solution to precipitate, filter, wash repeatedly like this for 2-3 times, filter, dry the obtained filter cake to obtain 26.9 kg of dry xylan, and add it to the dry xylan Add deionized water to make the xylan mass concentration 5%, adjust the pH value to 4.5-5.0 and then heat it, and put it into the enzyme membrane reactor after heating to 45-55°C, where the...

Embodiment 2

[0034] Example 2: Grinding the selected corncobs, weighing 100 kg of the crushed corncobs, adding 4mol / L sodium hydroxide solution according to 8 times the weight of the corncobs, treating at 45°C for 8h, and filtering to obtain the dissolved xylan solution, adjust the pH value of the eluate to 5.0-7.0, then add ethanol that is 1 times the volume of the feed solution, and place it at a low temperature of 4°C for 6-12 hours to make the xylan form a flocculent precipitate. After filtering the precipitate, remove the precipitate with a small amount Dissolve in ionic water, then add ethanol with 1 times the volume of the feed solution to precipitate, filter, wash repeatedly like this for 2-3 times, filter, dry the obtained filter cake to obtain 20.8 kg of dry xylan, add to the dry xylan Add deionized water to make the xylan mass concentration 10%, adjust the pH value to 4.5-5.0 and then heat it, and put it into the enzyme membrane reactor after heating to 45-55°C, where the operati...

Embodiment 3

[0035] Example 3: Grinding the selected corncobs, weighing 100 kg of the crushed corncobs, adding 1mol / L sodium hydroxide solution according to 12 times the weight of the corncobs, treating at 60°C for 16h, and filtering to obtain the dissolved xylan solution, adjust the pH value of the eluate to 5.0-7.0, then add ethanol twice the volume of the feed solution, and place it at a low temperature of 4°C for 6-12 hours to make the xylan form a flocculent precipitate. After filtering the precipitate, remove the precipitate with a small amount Dissolve in ionic water, then add ethanol with 2 times the volume of the feed liquid to precipitate, filter, wash repeatedly like this for 2-3 times, filter, dry the obtained filter cake to obtain 24.6 kg of dry xylan, and add it to the dry xylan Add deionized water to make the xylan mass concentration 2%, adjust the pH value to 4.5-5.0 and then heat it, and put it into the enzyme membrane reactor after heating to 45-55°C, where the operating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com