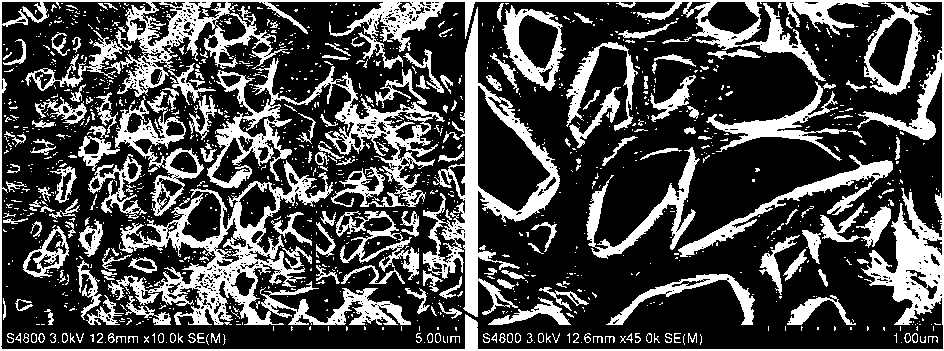

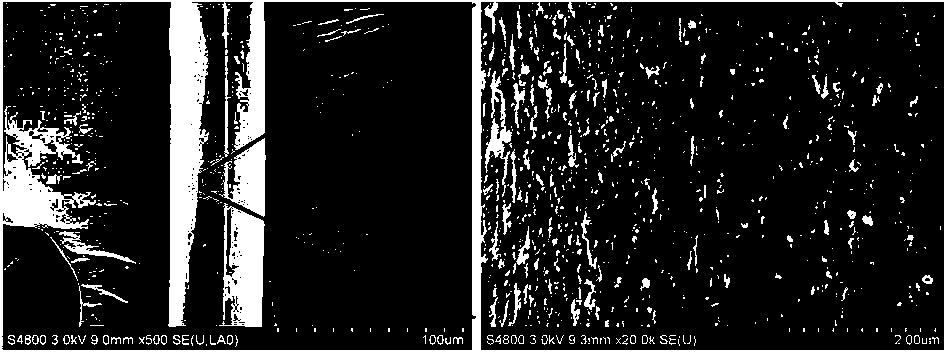

Bionic regenerated silk fibroin filament fiber and preparation method thereof

A technology for regenerating silk fibroin and filament fibers, which is applied in the direction of single-component fibroin artificial filament, dry spinning method, wet spinning method, etc., can solve the problems of poor mechanical properties and lack of natural silk fibril structure, etc. Achieve the effect of low cost, efficient preparation process and controllable preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

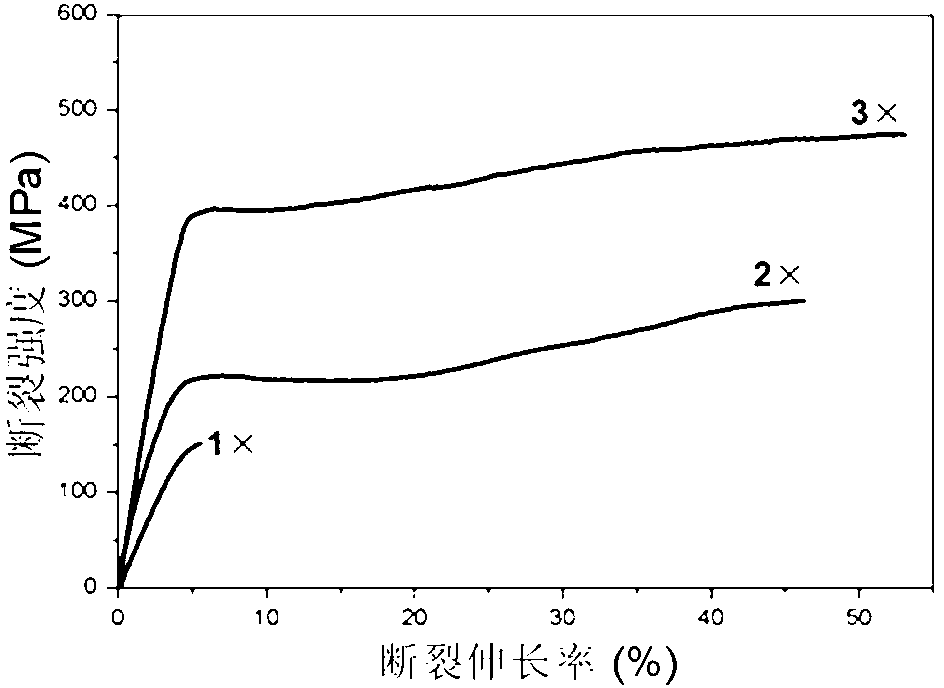

Embodiment 1

[0032] A preparation method of bionic regenerated silk fibroin filament fiber, comprising the steps of:

[0033] (1) Put 0.5Kg of leftover raw silk (by-product of silkworm cocoon reeling in silk reeling factory) into 10 liters of sodium carbonate aqueous solution with a mass fraction of 0.1%, boil for 30 minutes, repeat 3 times, and then dry naturally to obtain pure silk Silk fibroin;

[0034] (2) Prepare 2 liters of formic acid / calcium chloride mixed solution with a mass fraction of 98% formic acid, wherein the content of calcium chloride is 5.0%. After the solution is mixed evenly, put pure silk fibroin into formic acid / calcium chloride In the mixed solution, stir at room temperature for 3 hours to obtain a silk fibroin solution with a mass fraction of 25.0%, which is purified by filtration and ultrasonically defoamed for 0.5 hours to make a spinning stock solution;

[0035] (3) Under the action of 1.0MPa nitrogen, use a spinning hole with a diameter of 0.9mm, and at a temp...

Embodiment 2

[0039](1) Put 1 kilogram of silkworm cocoons into 20 liters of sodium carbonate solution with a mass fraction of 0.05%, boil for 30 minutes, repeat 3 times, then dry naturally to obtain pure silk fibroin;

[0040] (2) Using phosphoric acid with a mass fraction of 98%, prepare 2 liters of phosphoric acid / hydroxyapatite mixture, wherein the content of hydroxyapatite is 10.0%. After the solution is evenly mixed, put pure silk fibroin into the phosphoric acid / hydroxyapatite mixture, stir at room temperature for 6 hours, and obtain a silk fibroin solution with a mass fraction of 10.0%, which is purified by filtration and defoamed by ultrasonic waves for 0.5 hours. into spinning dope;

[0041] (3) Under the action of 0.5MPa nitrogen, use a spinning hole with a diameter of 0.9mm, and at a temperature of 20°C, spray the silk fibroin spinning stock solution at a speed of 3g per minute, and then enter the silk fibroin spinning solution with a concentration of 60%. In the ammonium sulfa...

Embodiment 3

[0044] (1) Put 1 kilogram of cocoon silk into 20 liters of sodium carbonate solution with a mass fraction of 0.1%, boil for 30 minutes, repeat 3 times, then dry naturally to obtain pure silk fibroin;

[0045] (2) Using formic acid with a mass fraction of 98%, prepare 1 liter of formic acid / hydroxyapatite mixture, wherein the content of hydroxyapatite is 10.0%. After the solution is evenly mixed, put pure silk fibroin into the formic acid / hydroxyapatite mixture, stir at room temperature for 4 hours, and obtain a silk fibroin solution with a mass fraction of 15.0%, which is purified by filtration and defoamed by ultrasonic waves for 0.5 hours. into spinning dope;

[0046] (3) Under the temperature condition of 30°C, spray silk fibroin protein into the hot air at a speed of 5g per minute to form nascent fibers; the nascent fibers are then drawn twice, and the first drafting ratio is 1.0 times , the second drafting ratio is 1.5 times to obtain filament fibers with stable structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com