Solvent type transparent nanometer thermal insulation sizing agent and application method thereof

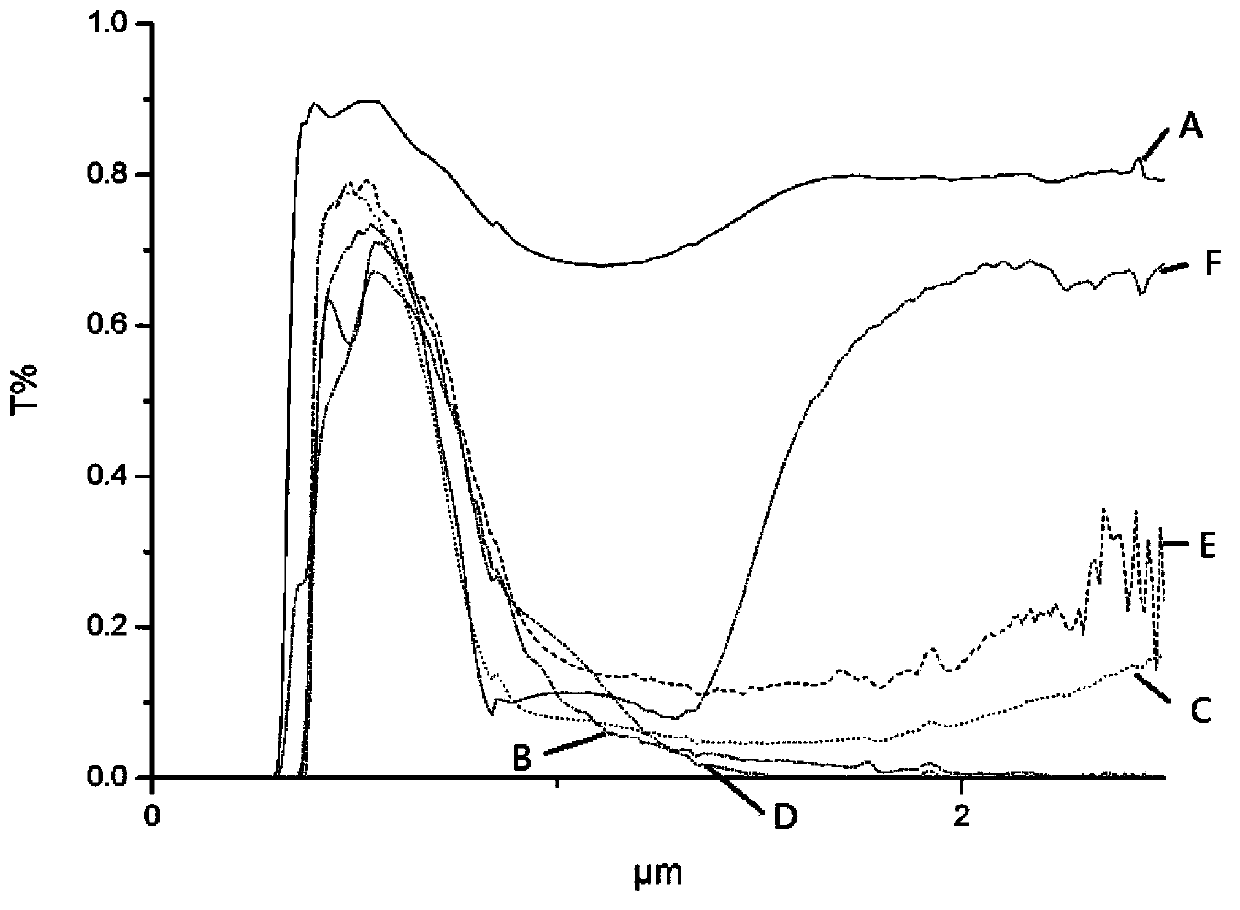

A nano heat-insulating, solvent-based technology, applied in the field of coatings, can solve the problems of low transmittance, short storage time, single variety of heat-insulating particles, etc., achieve improved weather resistance and chemical resistance, and strong solar spectrum selectivity , Inhibit the effect of Cr6+

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] 1) Preparation of nano thermal insulation particles

[0077] Preparation of Nano WO 3 -x Powder: Dissolve ammonium tungstate in deionized water at room temperature, stir and add 65% nitric acid dropwise at the same time, until the pH value of the solution system is in the range of 1~3, slowly warm up to 80℃, keep for 1 hour, and cool To room temperature, until the precipitate is completely precipitated; filter, wash with deionized water until there is no impurity ions, and dry at 90°C for 24h; heat and calcinate, the heating rate is not more than 5°C / min, keep at 500°C for 3h, and then not more than 5°C / min cooling rate annealing, after cooling, placed in a high-energy ball mill, dry milling / wet milling to pulverize to obtain nano-WO3 powder; WO3 powder is placed in a tube furnace, and H2 / N2 mixed gas (H 2 : N 2 =1:9), reduce at 350°C for 1h, then pass in N2 gas, keep at 800°C for 1h, and anneal at a cooling rate of not more than 5°C / min to obtain nano-WO3-x powder;

[0078...

Embodiment 2

[0083] Example 2, same as Example 1, except that in the preparation of nano-ITO / Cr2O3 mixed powder, the heat-preservation condition of the heating and calcination stage is 1h at 1000°C, and the measured primary average particle size of the nano-particles is 40nm; the nano-slurry preparation is diluted The agent is toluene, the dispersant is polyether-modified trisiloxane, and the leveling agent is BYK306. The carrier is a light-curable acrylic resin composition, acrylate elastomer is 8%, and polyurethane acrylate is 40. %, 15% for trifunctional acrylate, 16% for aliphatic urethane acrylate, 10% for viscosity promoter, 5% for nano-silica-4HBAGE, 1% for functional additives, 5 for photoinitiator %; In the test method, it is coated on 3mm ordinary transparent glass by a wire rod coater, and after drying, the film is cured by UV light, and the film thickness is controlled to 3μm;

Embodiment 3

[0084] Example 3 is the same as Example 1, except that the diluent in the preparation of nano-slurry is a mixture of toluene and ethyl acetate (toluene: ethyl acetate = 1:1), and the dispersing agent is methoxy propyl acetate and methyl acetate. Acrylic acid mixture (propyl methoxyacetate: methacrylic acid=1:2), the leveling agent is BYK307;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com