Three-dimensional porous cobalt-based/graphene composite material and preparation method thereof

A composite material, three-dimensional porous technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of unstable material structure and performance, difficult to ensure stable product quality, and cumbersome preparation process, and achieve rich raw materials and improve circulation. Stable performance and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]The preparation method of graphene oxide among the present invention is as follows:

[0036] In a water bath at 0-20°C, add 3-5g of graphite powder into 100-150mL of concentrated sulfuric acid, add 10-20g of potassium permanganate while stirring, stir for 3-4 hours, and when the temperature rises to 30-35°C, add 300-500mL Deionized water, stirred for 1-3 hours, added 15-25mL of 30% hydrogen peroxide solution, stirred for 5-20 minutes, centrifuged, washed repeatedly with 5% hydrochloric acid solution and deionized water After drying, graphene oxide is obtained.

[0037] The assembly and testing methods of lithium-ion batteries are as follows:

[0038] The three-dimensional porous cobalt-based / graphene composite material of the present invention and 20wt.% binder (solid content is 2wt.% styrene-butadiene rubber-sodium carboxymethyl cellulose emulsion or concentration is 0.02g / mL poly N-methylpyrrolidone solution of vinylidene fluoride) mixed with 20wt.% conductive agent ...

Embodiment 1

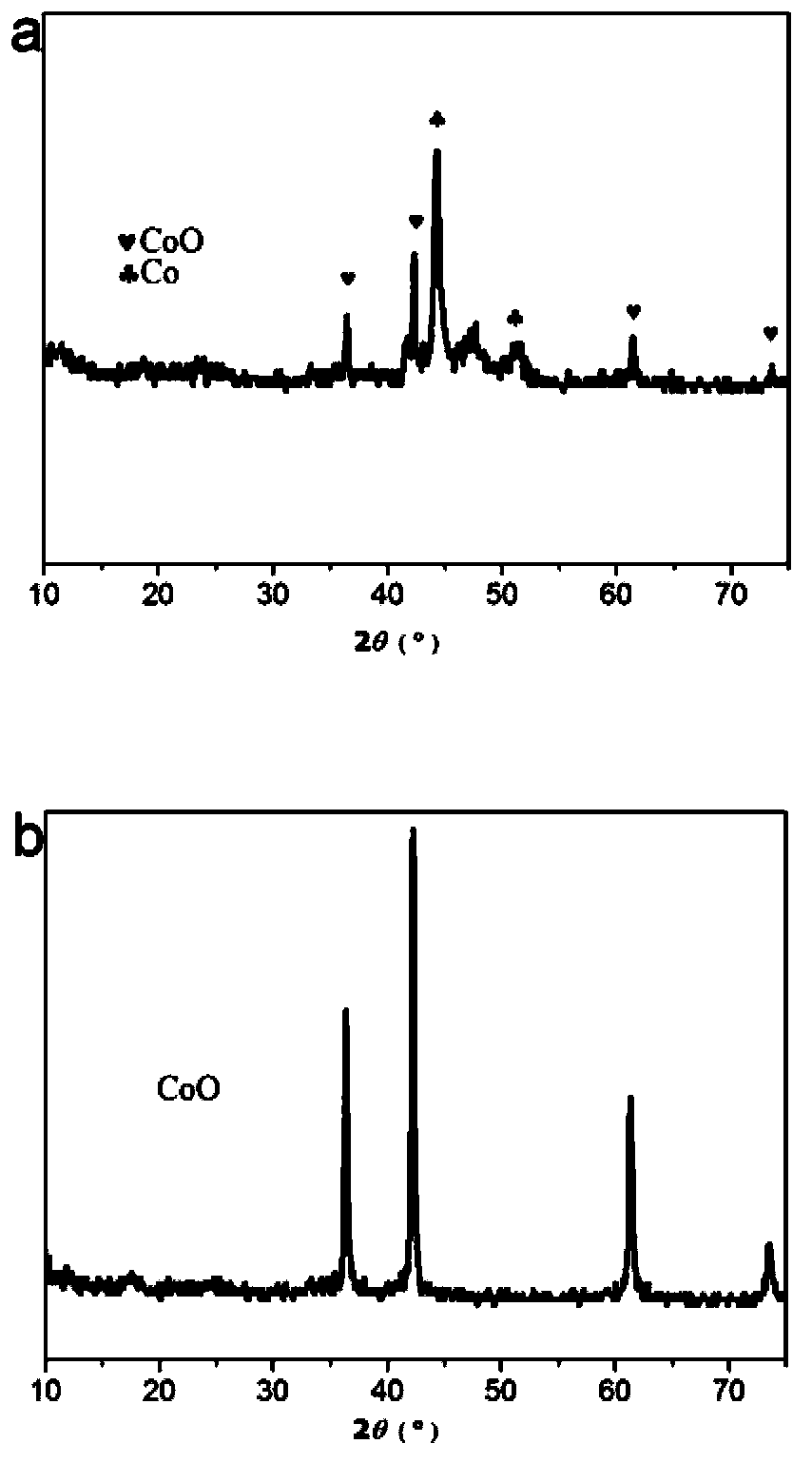

[0041] Disperse 50mg of graphene oxide and 250mg of cobalt acetate tetrahydrate (about 60mg of cobalt element) in 50mL of absolute ethanol, ultrasonically disperse it for 45 minutes to make it uniform, and then put the mixed solution into the reaction kettle through 190°C solvothermal After 20 hours of reaction, freeze-dry for 24 hours at -80 ° C and a pressure of 5 Pa to obtain a three-dimensional porous cobalt-based / graphene composite material. The cobalt-based component in this material is mainly a mixture of simple cobalt and cobaltous oxide. The particle size of the cobalt-based material is 500nm, the proportion of the cobalt-based material in the composite material is 80%, and the pore diameter of the porous material is about 6 μm.

[0042] The three-dimensional porous cobalt-based / graphene composite material of the prepared lithium-ion battery was assembled into a battery for charge and discharge tests. The first charge and discharge Coulombic efficiency was 72%, and the...

Embodiment 2

[0045] Disperse 100mg of graphene oxide and 125mg of cobalt acetate tetrahydrate (about 30mg of cobalt element) in 50mL of absolute ethanol, and disperse it evenly by ultrasonication for 60 minutes, then put the mixed solution into the reaction kettle and undergo solvothermal heating at 180°C. After 20 hours of reaction, freeze-dry for 18 hours at -70°C and a pressure of 10 Pa to obtain a three-dimensional porous cobalt-based / graphene composite material. 400nm, the proportion of cobalt-based material in the composite material is 40%, and the pore diameter of the porous material is about 3 μm.

[0046] A lithium-ion battery silicon-graphene composite material prepared was assembled into a battery for charge and discharge tests. The first charge and discharge Coulombic efficiency was 65%, and the first reversible capacity was 1081mAh / g. The charge-discharge test was carried out at a current density of 200mA / g, and the reversible capacity of the 20th cycle was still 900mAh / g. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com