Electro-polymerizable chemically-modified electrode organic material and application of electrode organic material in ultra-trace TNT (Trinitrotoluene) detection

A chemical modification and organic material technology, applied in the field of electrochemical sensing, can solve the problems of large electrode consumption, limited application, cumbersome operation, etc., and achieve the effect of easy realization, easy control of shape and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: the synthesis of compound TCAC:

[0069]

[0070] Synthesis of N-(6-bromo-hexane)-carbazole

[0071] 10g of carbazole and 9.48mL of 1,6-dibromohexane were dissolved in tetrahydrofuran and added dropwise to the sodium hydride that had washed off the oxide film, and stirred at room temperature for 24h. The remaining sodium hydride was filtered, and the filtrate was concentrated. A white solid was obtained by column chromatography with a mixed solvent of dichloromethane and petroleum ether as the eluent, and the yield was 45%. 1 H NMR (500MHz, CDCl 3 ):δ8.10(d,2H),δ7.45(t,2H),δ7.40(d,2H),δ7.22(t,2H),δ4.31(t,2H),δ3.36 (t,2H), δ1.92(m,2H), δ1.84(m,2H), δ1.47(m,2H), δ1.40(m,2H).

[0072] Synthesis of 2-bromo-9,9-(N-carbazole-hexyl)fluorene

[0073] 2.03g of 2-bromofluorene in tetrahydrofuran was slowly added dropwise to 0.7g of N-(6-bromo-hexane)-carbazole and sodium hydride in tetrahydrofuran, and refluxed for 48 hours. Cool down, filter the remaining ...

Embodiment 2

[0078] Embodiment 2: Preparation of chemically modified electrode membrane

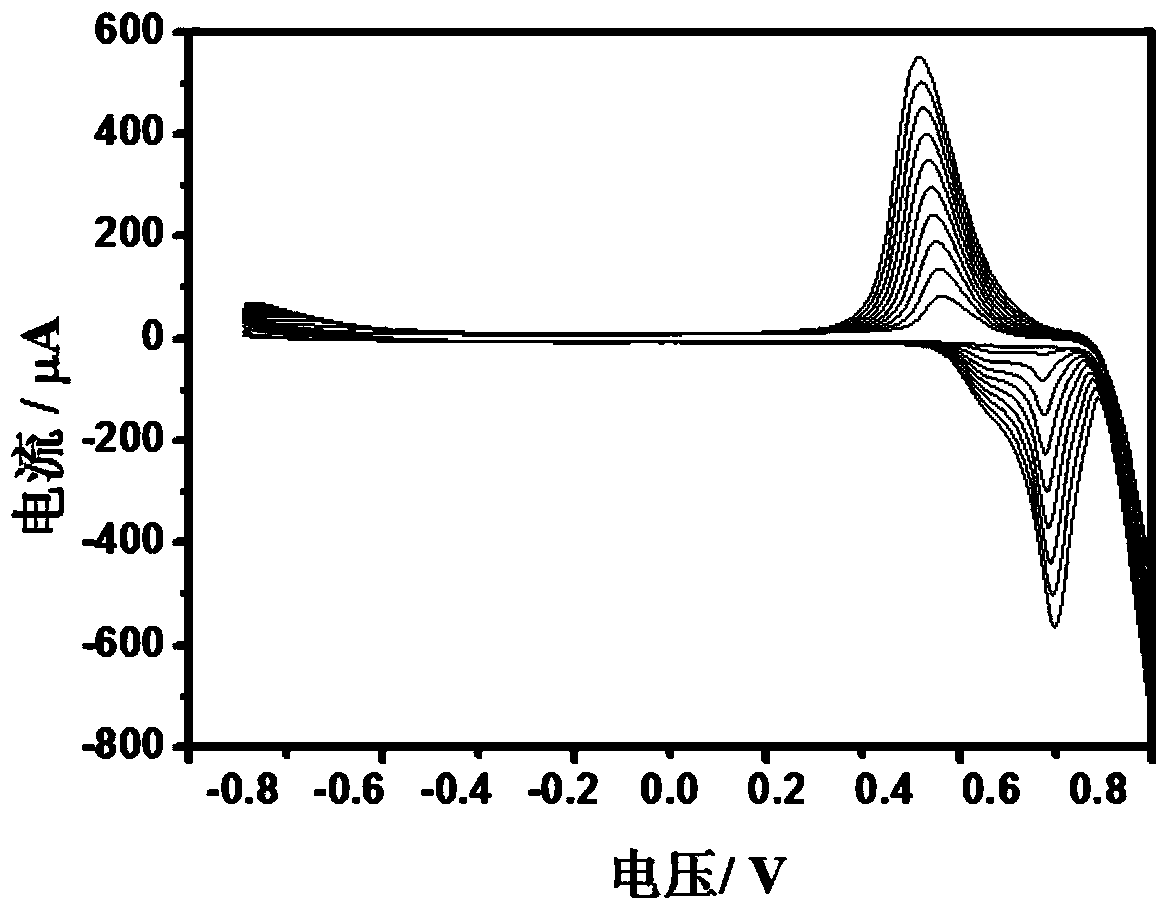

[0079] The chemically modified electrode membrane was prepared by cyclic voltammetry, using tetrabutylammonium hexafluorophosphate as the electrolyte, and the concentration of TCAC was 0.5 mg / mL. Each scan cycle is accompanied by the dedoping process of each layer of chemically modified electrode film. We choose 0.9V as the upper limit of the cyclic voltammetry scanning range. In order to improve the dedoping performance of the chemically modified electrode film, we set the lower limit of the cyclic voltammetry scanning range to be -0.8V, and then set the cyclic voltammetry scanning range to be -0.8V~0.9V. Set the scanning speed to 200mV / s, and the number of scanning circles to 10 circles (such as figure 1 ).

Embodiment 3

[0080] Embodiment 3: post-treatment of chemically modified electrode membrane

[0081] The chemically modified electrode membrane was cleaned with a mixed solvent of acetonitrile and dichloromethane with a volume ratio of 3:2. Flush with high-purity nitrogen for 5 minutes, and heat at 45°C for 4 hours under vacuum to remove the solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com