Non-phosphorus scale inhibition dispersant and application thereof

A phosphorus-free scale inhibitor and dispersant technology, applied in scale removal and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve excessive drainage, large waste of water resources, waste of water resources, etc. problem, to achieve the effect of enhanced polarity, excellent corrosion inhibition performance, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

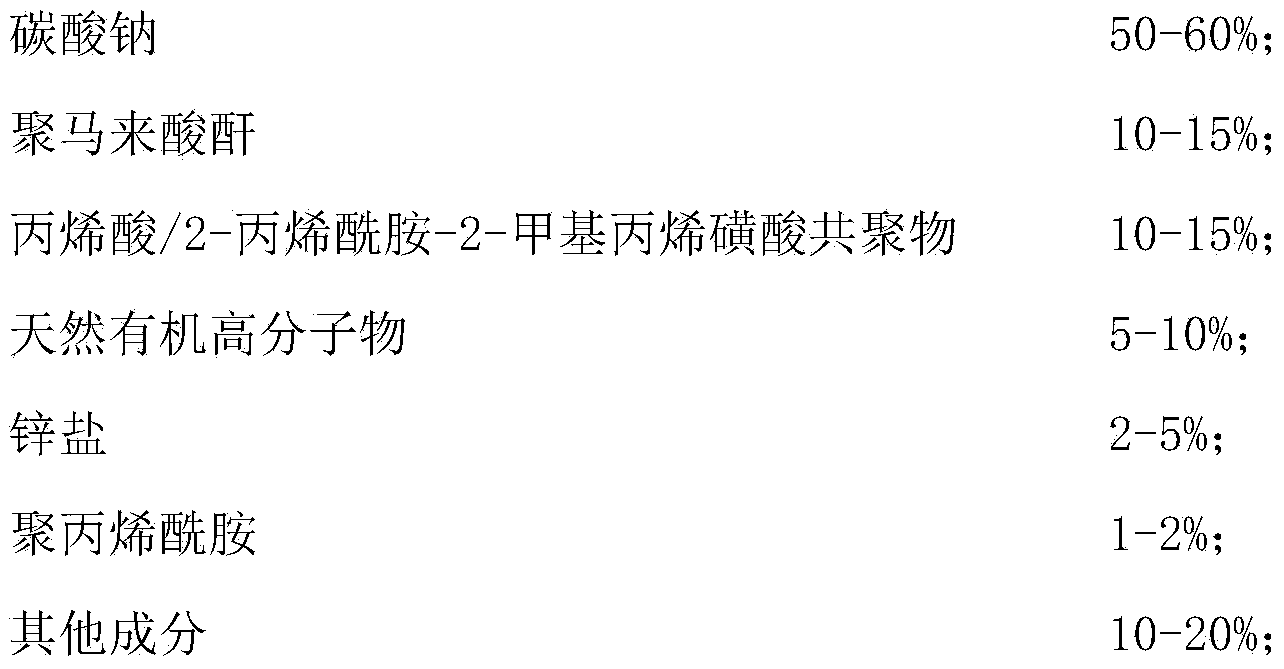

[0029] A phosphorus-free scale inhibitor dispersant, which is characterized in that it is mixed from the following raw materials: 1) sodium carbonate, 2) acrylic acid / 2-acrylamide-2-methacrylic acid copolymer, 3) polymaleic acid Acid anhydride, 4) natural organic polymer substance, 5) zinc salt, 6) polyacrylamide, 7) other components, the mass percentage of each raw material is:

[0030]

[0031] The other ingredients are sodium carboxymethylcellulose and dodecylamine; the zinc salt is zinc chloride; and the natural organic polymer is a mixture of sodium gluconate and tannin.

[0032] The above-mentioned non-phosphorous scale inhibitor dispersant is applied to circulating cooling water, and 65 mg of non-phosphorous scale inhibitor dispersant is added to each liter of circulating cooling water.

Embodiment 2

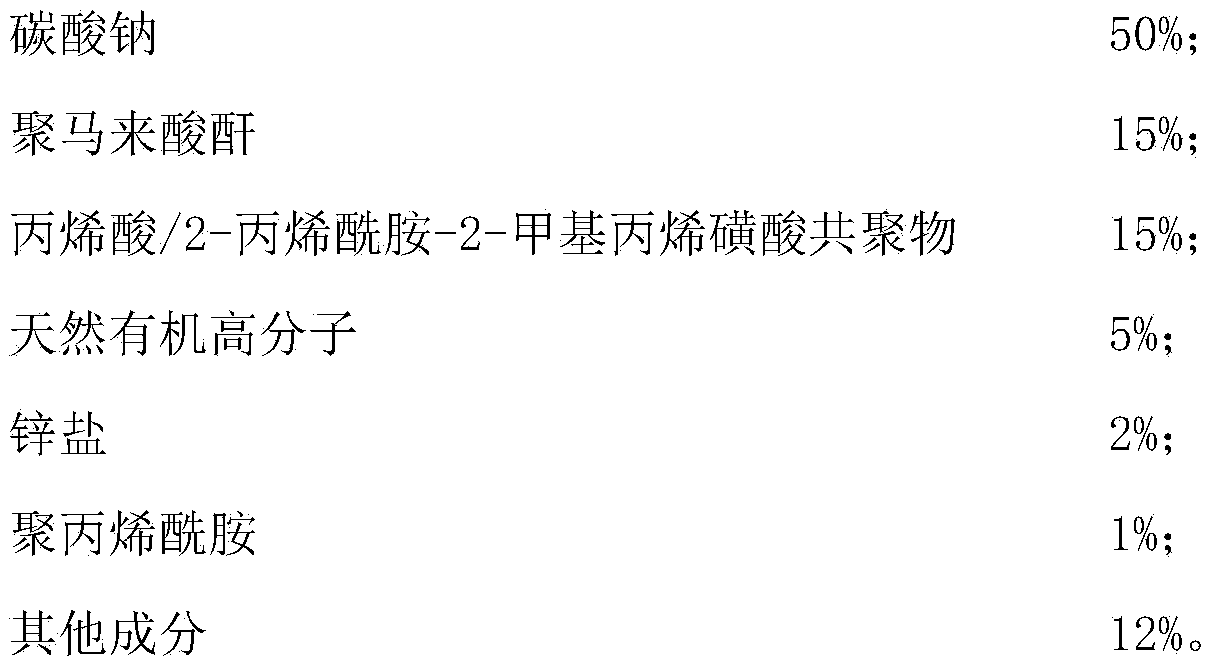

[0034] A phosphorus-free scale inhibitor dispersant, which is characterized in that it is mixed from the following raw materials: 1) sodium carbonate, 2) acrylic acid / 2-acrylamide-2-methacrylic acid copolymer, 3) polymaleic acid Acid anhydride, 4) natural organic polymer substance, 5) zinc salt, 6), polyacrylamide, 7) other components, the mass percentage of each raw material is:

[0035]

[0036] The other ingredients are sodium carboxymethylcellulose and dodecylamine; the zinc salt is zinc chloride; and the natural organic polymer is sodium gluconate.

[0037] The above-mentioned non-phosphorous scale inhibitor dispersant is applied to circulating cooling water, and 60 mg of non-phosphorous scale inhibitor dispersant is added to each liter of circulating cooling water.

Embodiment 3

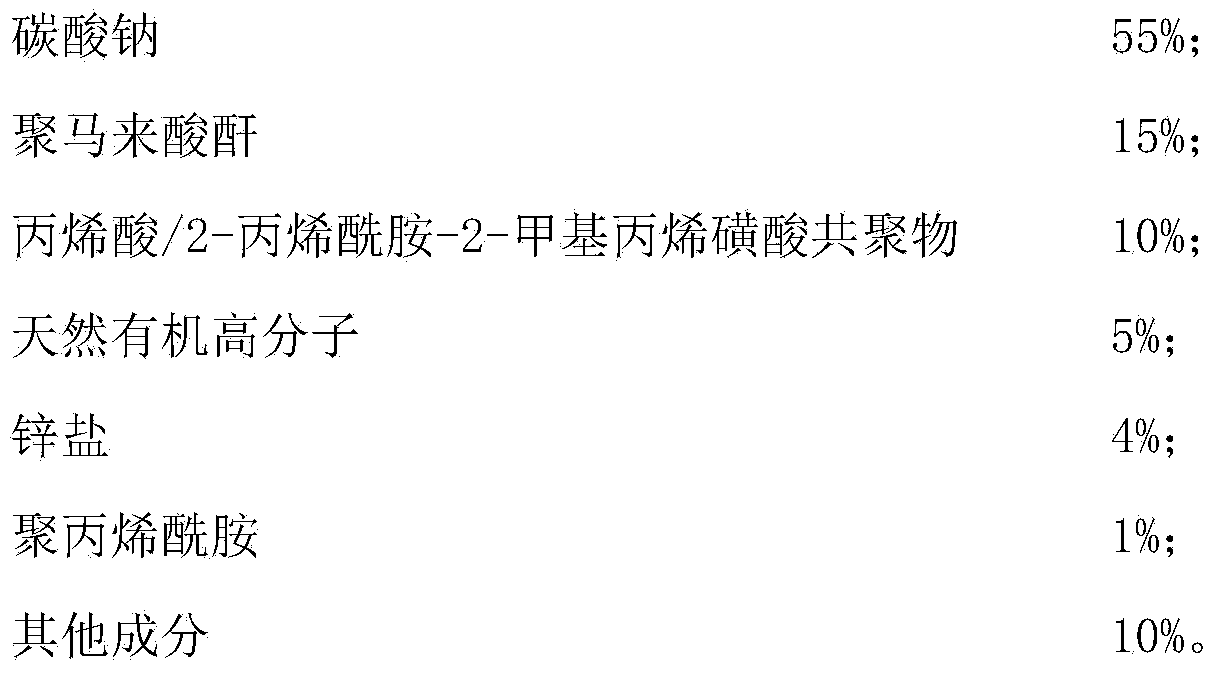

[0039] A phosphorus-free scale inhibitor dispersant, which is characterized in that it is mixed from the following raw materials: 1) sodium carbonate, 2) acrylic acid / 2-acrylamide-2-methacrylic acid copolymer, 3) polymaleic acid Acid anhydride, 4) natural organic polymer substance, 5) zinc salt, 6), polyacrylamide, 7) other components, the mass percentage of each raw material is:

[0040]

[0041] The other components are acrylic acid-hydroxypropyl acrylate copolymer; the zinc salt is zinc sulfate; and the natural organic macromolecule is lignin and its derivatives.

[0042] The above-mentioned non-phosphorous scale inhibitor dispersant is applied to circulating cooling water, and 80 mg of non-phosphorus scale inhibitor dispersant is added per liter of circulating cooling water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com