Method for preparing graphene composite with low percolation threshold value and high heat stability

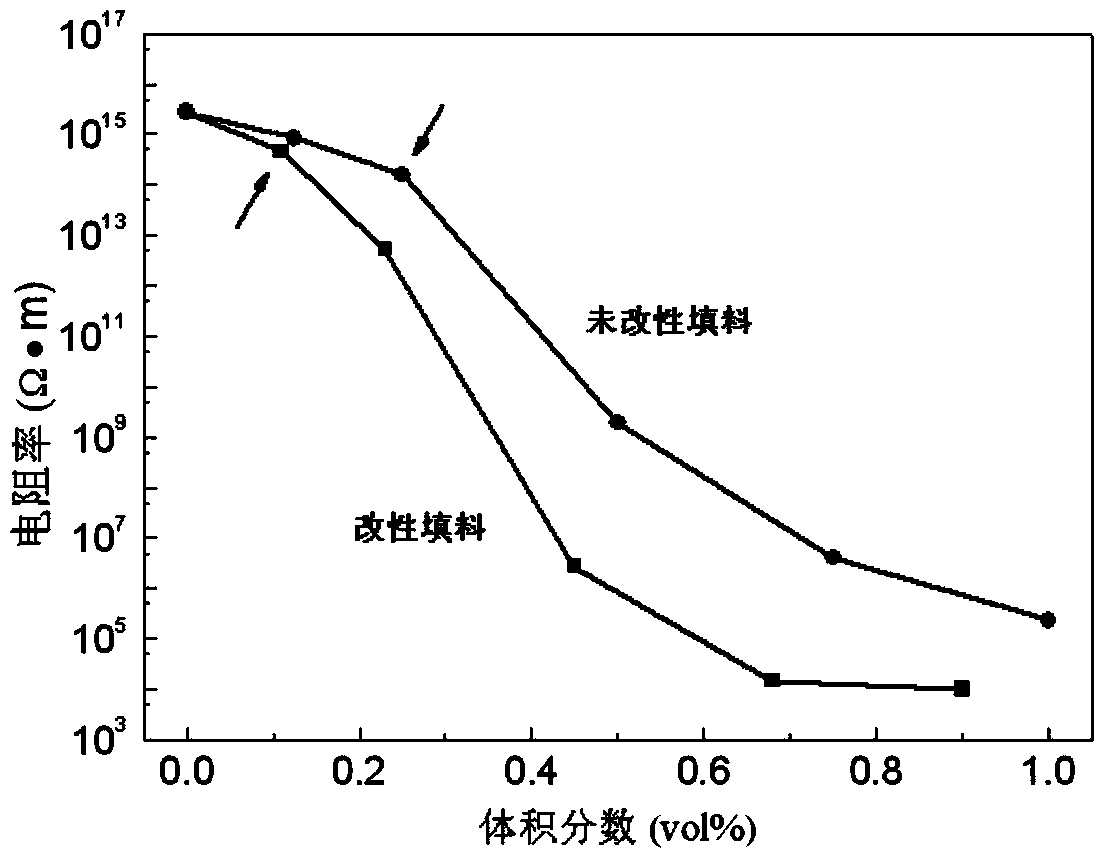

A technology with high thermal stability and percolation threshold, which is applied in the field of preparation of graphene composite materials with low percolation threshold and high thermal stability, can solve the problem of damage to material processing and mechanical properties, irreversible weakening of electrical properties, and unsatisfactory thermal stability and other problems, to achieve the effect of excellent thermal stability, stable phase area size and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a method for preparing a low percolation threshold and high thermal stability ternary graphene-based conductive polymer composite material, comprising the following steps:

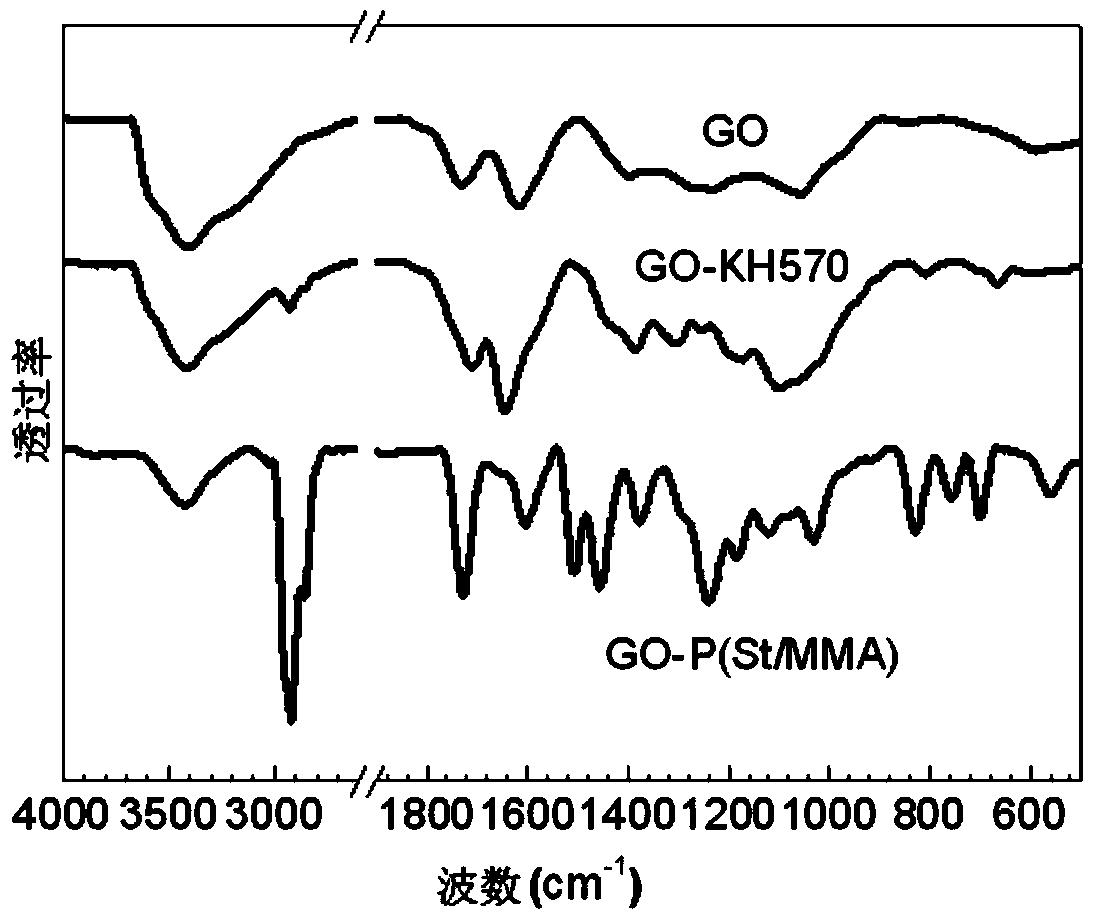

[0032] Step (1), graphene oxide (GO) grafted with γ-methacryloxypropyltrimethoxysilane (KH-570)

[0033] Weigh 500mg of graphene oxide (GO), add 500mL of deionized water, ultrasonicate for 5h and stir overnight, then disperse for 30min at 50% power of the cell crusher, and record it as solution A; add 2g of KH-570 to 100mL of pH=4.0 Deionized water was hydrolyzed at room temperature for 1 hour, which was recorded as solution B; the two solutions A and B were mixed, and reacted at 25°C for 24 hours. After the end, it was centrifuged at high speed and washed with ethanol for 3 times; the product was vacuum-dried at 60°C for 24 hours to obtain GO-KH570;

[0034] Step (2), GO-KH570 miniemulsion polymerization grafted styrene (St), methyl methacrylate copolymer (MMA)

[0035]W...

Embodiment 2

[0039] This embodiment relates to a method for preparing a low percolation threshold and high thermal stability ternary graphene-based conductive polymer composite material, comprising the following steps:

[0040] Step (1), graphene oxide grafted with γ-methacryloxypropyltrimethoxysilane (KH-570)

[0041] Weigh 100mg of graphene oxide (GO), add 150mL of deionized water, sonicate for 2h and stir overnight, then disperse for 30min at 50% power of the cell crusher, and record it as solution A; add 1g of KH-570 to 100mL pH=4.0 Deionized water was hydrolyzed at room temperature for 1 hour, which was recorded as solution B; the two solutions A and B were mixed, reacted at 50°C for 20 hours, and then centrifuged at high speed and washed with ethanol for 3 times; the product was vacuum-dried at 60°C for 24 hours to obtain GO-KH570;

[0042] Step (2), GO-KH570 miniemulsion polymerization grafted styrene (St), methyl methacrylate copolymer (MMA)

[0043] Weigh 300mg GO-KH570, 15g styr...

Embodiment 3

[0047] This embodiment relates to a method for preparing a low percolation threshold and high thermal stability ternary graphene-based conductive polymer composite material, comprising the following steps:

[0048] Step (1), graphene oxide grafted with γ-methacryloxypropyltrimethoxysilane (KH-570)

[0049] Weigh 500mg of graphene oxide (GO), add it into 500mL deionized water, ultrasonicate for 5h and stir overnight, then disperse for 30min at 50% power of the cell crusher, and record it as solution A; add 2g KH-570 to 500mL pH=4.0 Deionized water was hydrolyzed at room temperature for 1 hour, which was recorded as solution B; the two solutions A and B were mixed, reacted at 75°C for 16 hours, and then centrifuged at high speed and washed with ethanol for 3 times; the product was vacuum-dried at 60°C for 24 hours to obtain GO-KH570;

[0050] Step (2), GO-KH570 miniemulsion polymerization grafted styrene (St), methyl methacrylate copolymer (MMA)

[0051] Weigh 200mg GO-KH570, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com