High-efficiency desulfurizing combined solvent

A solvent and high-efficiency technology, applied in the field of renewable and high-efficiency desulfurization combined solvents, can solve the problems of low corrosiveness, low absorption rate and high cost, and achieve the effects of high selectivity, low energy consumption and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Simulated SO in flue gas 2 Gas volume fraction 0.4%, CO 2 The gas volume fraction is 12%, and the rest is supplemented by air. A high-efficiency desulfurization combined solvent of the present invention, the mass percentage of ethylenediamine in the first component is 1.8%, the mass percentage of N-methylpyrrolidone in the second component is 1.2%, and the phosphoric acid in the third component adjusts the pH to neutral nature, and the rest is water.

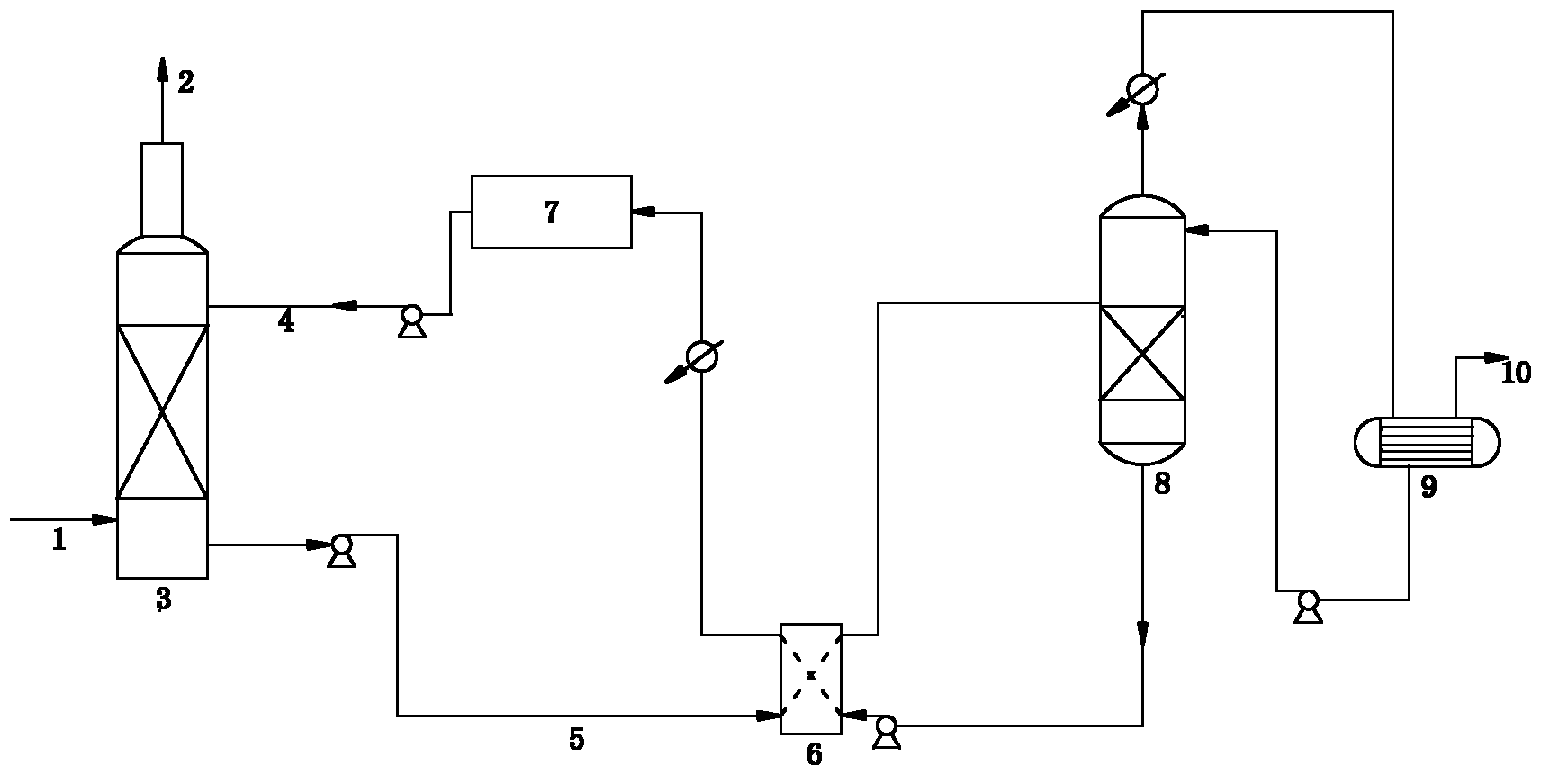

[0018] The entire process flow of this embodiment is: the simulated flue gas enters the absorption tower from the bottom of the absorption tower, the high-efficiency desulfurization combined solvent enters from the top of the absorption tower, and the packing surface in the tower contacts with the flue gas countercurrently, and absorbs SO through the barren liquid. 2 The clean flue gas after the gas is discharged from the top of the absorption tower to absorb SO 2 The rich liquid after the gas is discharged from the bo...

Embodiment 2

[0021] Simulated SO in flue gas 2 Gas volume fraction 0.4%, CO 2 The gas volume fraction is 12%, and the rest is supplemented by air. A high-efficiency desulfurization combined solvent of the present invention, the mass percentage of ethylenediamine in the first component is 1%, the mass percentage of diethylenetriamine is 1%, and the mass percentage of N-methylpyrrolidone in the second component is 1%, The boric acid in the third component adjusts the pH value to 6, and the rest is water.

[0022] The whole process flow of this embodiment is the same as that of Embodiment 1.

[0023] The simulated flue gas absorption temperature is 40°C, and the desorption temperature is 102°C. After treatment, the desulfurization rate can reach more than 98%.

Embodiment 3

[0025] Simulated SO in flue gas 2 Gas volume fraction 0.5%, CO 2 The gas volume fraction is 12%, and the rest is supplemented by air. A high-efficiency desulfurization combined solvent of the present invention, the mass percent of triethylenetetramine in the first component is 1%, the mass percent of propylenediamine is 1%, and the mass percent of dimethyl sulfoxide in the second component is 2%, Phosphoric acid in the third component adjusts the pH value to neutral, and the rest is water.

[0026] The whole process flow of this embodiment is the same as that of Embodiment 1.

[0027] The simulated flue gas absorption temperature is 50°C, and the desorption temperature is 108°C. After treatment, the desulfurization rate can reach more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com