Technological method for preparing 1, 3-propylene glycol by adopting glycerin and hydrogen

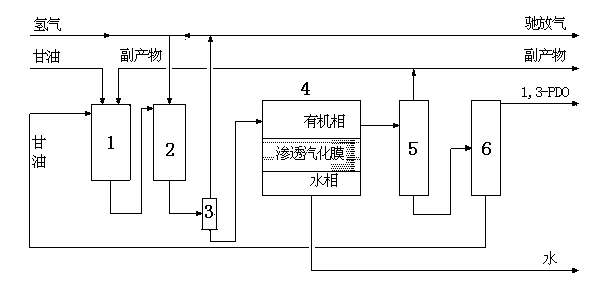

A process method and technology for propylene glycol, which are applied in the field of hydrogenation to prepare 1,3-propylene glycol, can solve the problems of high energy consumption, poor reaction stability and high reaction temperature, and achieve the effects of stable catalyst, mild reaction conditions and increased production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

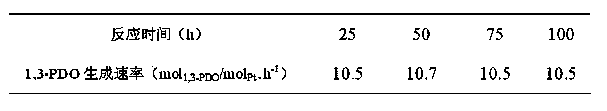

Embodiment 1

[0031] one. Catalyst preparation and handling

[0032] Pour 100.0 grams of zirconium hydroxide into 50 ml of water dissolved with 2.4 grams of ammonium metatungstate, mix thoroughly, keep at 90~100°C for 20 hours, bake at 110°C to an appropriate level, extrude, dry at 110°C, and roast at 700°C After 3 hours, a tungsten-zirconium composite oxide was obtained. Take 5.0 grams of tungsten-zirconium composite oxide and immerse it in a mixed solution of 3.18ml of boric acid aqueous solution containing 8.0mg boron / ml and 1.45ml of chloroplatinic acid aqueous solution containing 70.0mg platinum / ml for 8~10 hours, dry it at 450℃ Calcined for 2-4 hours to obtain the catalyst. The mass ratio of each element in the catalyst is Pt:B:W:Zr=2:0.5:10:61.2.

[0033] A tubular fixed-bed reactor with a length of 60 cm and an inner diameter of 10 mm was used. 4.4 grams of the above-mentioned catalysts are loaded, and the particle size is 20 to 40 mesh. The catalyst was reduced in hydr...

Embodiment 2

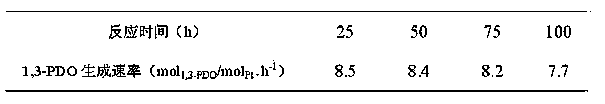

[0045] Following the reaction of Example 1 for 100 hours, the glycerin feed mass space velocity of this reactor 2 was adjusted to 0.7h -1 , other conditions were the same as in Example 1, the reaction was continued for 100 hours, and the formation rate of 1,3-propanediol was measured in Table 2 every 25 hours during the process.

[0046] Table 2

[0047]

Embodiment 3

[0049] Reactor 2 follows embodiment 1, after embodiment 2 continuous reaction totally 200 hours, the glycerol feed quality air velocity is adjusted to 0.3h -1 , other conditions are identical with embodiment 1. The reaction was continued for 100 hours, and the formation rate of 1,3-propanediol was measured at intervals of 25 hours during the process, as shown in Table 3.

[0050] table 3

[0051]

[0052] Table 1 ~ table 3 represent, procatalyst is through embodiment 1, embodiment 2 and embodiment 3 continuous reaction totally 300 hours in this reactor 2, wherein every reaction 100 hours changes the glycerol feed mass space velocity, from each table data can It can be seen that within 300 hours of continuous reaction, under different space velocities, the formation rate of 1,3-propanediol remains stable, indicating that changing the space velocity does not affect the stability of the formation rate of 1,3-propanediol, indicating that the catalyst is stable in the continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com