Feed for late-stage fattening and lactation promoting of livestock/poultry and ruminants

A fattening technology for ruminants, applied in animal feed, animal feed, animal husbandry, etc., can solve problems such as low feed digestion and utilization, poor absorption of nutrients, unbalanced fatty acids, etc., to improve the biological utilization of oils and fats , good effect of fattening or lactating, long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: 800kg fusing point is the palm oil of 52 degrees centigrade, soybean lecithin oil 100kg and peanut oil 20kg are metered into the mixing tank, the temperature is raised to 66-90 ℃ to dissolve the raw materials into a liquid state, then grind with a colloid mill, and then Use a shear emulsification pump to shear at a speed of 3600 rpm, and then use a high-pressure homogenizer to homogenize at a homogenizing pressure of 10-90Mpa, and then send the homogenized material into the liquid Shaped phytase 1kg, xylanase 1kg, lipase 2kg, lysine 8kg, VA1.2×10 8 IU and VE1×10 6 In the mixing tank of IU, after stirring and mixing evenly, the material is sent to the cooling tower with a pressure of 2-12Mpa for spray cooling, so that the high-melting point emulsified palm oil in the material produces natural physical crystallization, and then it is sent into a tank with 2kg of silicon dioxide added. After mixing evenly in the mixer, sieve and quantitatively pack to obtain...

Embodiment 2

[0029] Example 2: Measure 550 kg of emulsified lard and 350 kg of emulsified fish oil into a mixing tank, raise the temperature to 66-90 ° C, grind with a colloid mill, and then use a shear emulsification pump at 3600 rpm or above Rotating speed for shearing, and after shearing, use a high-pressure homogenizer to homogenize with a homogenizing pressure of 10-90Mpa, and then send the homogenized material into 1kg of liquid phytase with a pressure of 2-12Mpa. Xylanase 2kg, Lysine 8kg, Methionine 1kg, VA6×10 7 IU, VE6×10 5 IU and D-calcium pantothenate 0.4 kg in a mixing tank, stir and mix evenly, cool, measure and bottle to obtain a liquid nutritional oil product.

Embodiment 3

[0030] Embodiment 3: 400kg of the liquid nutritional oil product obtained in Example 2 and 600kg of puffed corn flour are sent into the mixer together and stirred and mixed for 3 minutes, and quantitative packaging is obtained after mixing evenly to obtain powdered nutritional oil powder containing 40% nutritional oil product.

[0031] In order to check the lactating effect of Example 1, two experimental groups were set, and 30 dairy cows were selected for feeding for 30 days in each group. The control group used the purchased feed 1, and the experimental group used the feed of Example 1 provided by the present invention. The effect is shown in Table 1.

[0032]

[0033] It can be known from Table 1 that using the feed of Example 1 provided by the present invention has a good lactation effect on dairy cows and improves the economic benefits of the pasture.

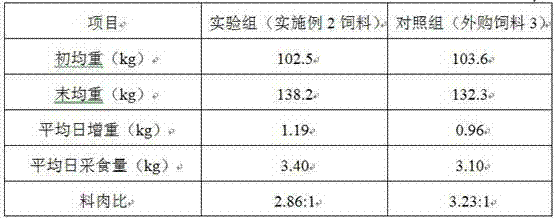

[0034] In order to check the fattening effect of Example 1, another two experimental groups were set, and 30 beef catt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com