Hybrid energy storage device with zinc ion battery and supercapacitor

A technology for supercapacitors and zinc ion batteries, applied in capacitors, battery electrodes, electrical components, etc., to achieve the effect of simple preparation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

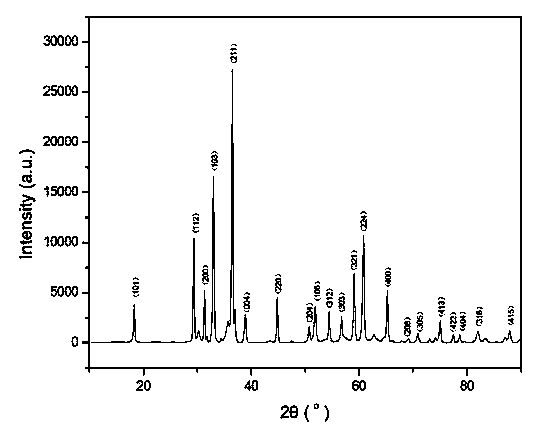

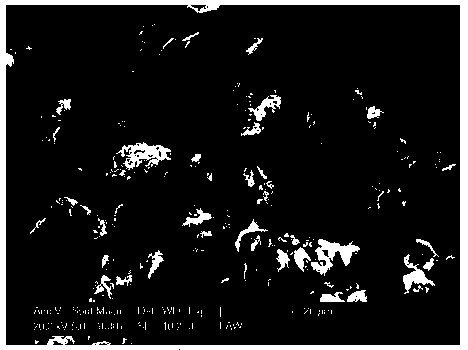

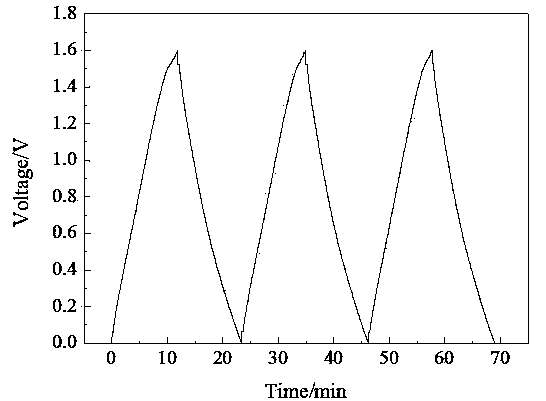

[0029] Weigh manganese carbonate, citric acid, and zinc carbonate according to the ratio of substances by volume 1:6:6. Manganese carbonate and citric acid were mixed evenly in water by magnetic stirring, heated to 60°C, reacted at constant temperature for 30 minutes, added zinc carbonate, continued to stir for 2 hours, cooled to room temperature, filtered the resulting product, washed with deionized water, and vacuumed at 60°C Dry to constant weight; calcinate the obtained product at 700°C for 2 hours to obtain zinc-manganese-oxygen composite metal oxide ZnMn 2 o 4 .

[0030] Weigh the positive electrode active material (ZnMn 2 o 4 The mass ratio of activated carbon is 40:60), VGCF, PTFE made of electrode film, pressed on a stainless steel mesh disc with a diameter of 16mm, and used as a positive electrode after drying; the negative active material was weighed according to the mass ratio of 80:10:10 ( The mass ratio of zinc to activated carbon is 40:60), VGCF, PTFE, make ...

Embodiment 2

[0033] Weigh the same amount of ferric oxide and zinc oxide and put them into a ball mill tank, the mass ratio of material to ball is 1:20, and ball mill for 3 hours to obtain the composite material precursor. The precursor was calcined at 700°C for 2 hours to obtain the zinc-iron oxide composite metal oxide ZnFe 2 o 4 .

[0034] Weigh the positive electrode active material (ZnFe 2 o 4 The mass ratio of activated carbon is 40:60), VGCF and PTFE are made into a slurry with a solid content of 60% in deionized water, coated on the titanium-free coating side of the activated carbon fiber cloth, and cut into a disc with a diameter of 16mm , dried, and rolled as the positive electrode sheet; according to the mass ratio of 80:10:10, the negative active material (the mass ratio of zinc to carbon nanotubes is 60:40), VGCF, and PTFE was weighed to make a slurry in deionized water. Coated on the non-titanium-coated side of the activated carbon fiber cloth, cut a disc with a diameter ...

Embodiment 3

[0037] According to the mass ratio of 1:2, zinc nitrate and cobalt nitrate were weighed to make an aqueous solution, and after stirring for 1 hour in a nitrogen atmosphere, sodium hydroxide was added to control the reaction time for 3 minutes. The product was washed and dried, and the obtained precursor was calcined at 600°C for 1 h to obtain the zinc-cobalt composite metal oxide ZnCo 2 o 4 .

[0038] Weigh the positive electrode active material (ZnCo 2 o 4 The mass ratio of activated carbon is 40:60), VGCF, PTFE, made a slurry with a solid content of 50% in deionized water, coated on a stainless steel mesh, dried, rolled, and cut into discs with a diameter of 16mm as Positive electrode sheet; according to the mass ratio of 75:15:10, weigh the negative active material (the mass ratio of zinc to graphene is 70:30), VGCF, and PTFE, and make a slurry with a solid content of 60% in deionized water. Coated on a stainless steel mesh, dried, rolled, and cut into a disc with a dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com