Device for epitaxial growth of silicon carbide

A technology of epitaxial growth and silicon carbide, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of increasing manufacturing costs, polluting epitaxial wafers, and large environmental pollution, and achieves improved uniformity, increased growth rate, and The effect of increasing the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

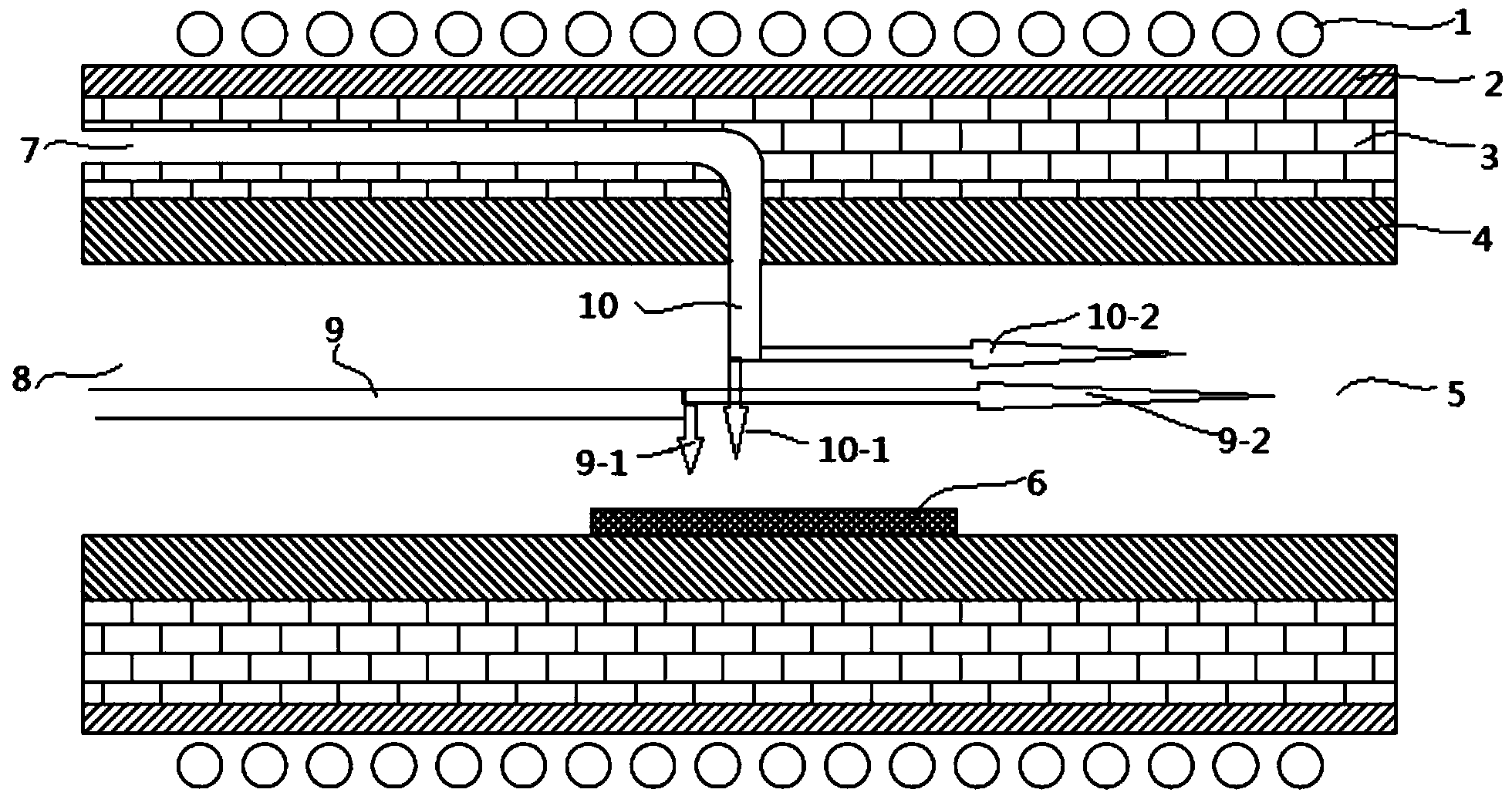

[0069] Such as figure 1 As shown, a silicon carbide epitaxial growth device of the present invention has a cylindrical shape and a cross-sectional radius of 18 cm, wherein a heating coil, a quartz wall, a graphite soft felt, a graphite support layer and the surrounding parts are arranged sequentially from the outside to the inside. Cuboid reaction chamber, the two ends of the reaction chamber are respectively equipped with an air inlet device and an air outlet device, the inner wall of the graphite support layer is coated with a coating, the coating is silicon carbide, and the thickness is 70um. Felt and vertically pass through the L-shaped air supply pipe of the graphite support layer, and the inner wall of the air supply pipe is coated with a coating.

[0070] The thickness of the quartz wall is 4 mm, and the thickness of the graphite support layer is 1.5 cm.

[0071] The gas supply pipes side by side covering the entire section of the reaction chamber are made of high-puri...

Embodiment 2

[0080] Such as figure 1 As shown, a kind of silicon carbide epitaxial growth device of the present invention, device is cylindrical, and cross-sectional radius is 20cm, wherein is provided with heating coil, quartz wall, graphite soft felt, graphite support layer and surrounded by it successively from outside to inside Cuboid reaction chamber, the two ends of the reaction chamber are respectively equipped with an air inlet device and an air outlet device, the inner wall of the graphite support layer is coated with tantalum carbide, and the thickness is 80um. Felt and vertically pass through the L-shaped air supply pipe of the graphite support layer, and the inner wall of the air supply pipe is coated with a coating.

[0081] The thickness of the quartz wall is 5 mm, and the thickness of the graphite support layer is 1.8 cm.

[0082] The gas supply pipes side by side covering the entire section of the reaction chamber are made of high-purity graphite, and the inner wall is coa...

Embodiment 3

[0091] Such as figure 1 As shown, a kind of silicon carbide epitaxial growth device of the present invention, device is cylindrical, and cross-sectional radius is 25cm, wherein is provided with heating coil, quartz wall, soft graphite felt, graphite support layer and surrounded by it successively from outside to inside Cuboid reaction chamber, the two ends of the reaction chamber are respectively equipped with an air inlet device and an air outlet device, the inner wall of the graphite support layer is coated with silicon carbide, and the thickness is 90um. Felt and vertically pass through the L-shaped air supply pipe of the graphite support layer, and the inner wall of the air supply pipe is coated with a coating.

[0092] The thickness of the quartz wall is 6 mm, and the thickness of the graphite support layer is 2.0 cm.

[0093] The air supply pipes covering the entire section of the reaction chamber side by side are made of high-purity graphite, and the inner wall is coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com