Technology for synthesizing sulfur quantum dots through oil-water interface method

An oil-water interface method, sulfur quantum technology, applied in the preparation/purification of sulfur, nanotechnology for materials and surface science, nanotechnology, etc. and other problems, to achieve the effects of uniform particle size distribution, mild reaction conditions, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

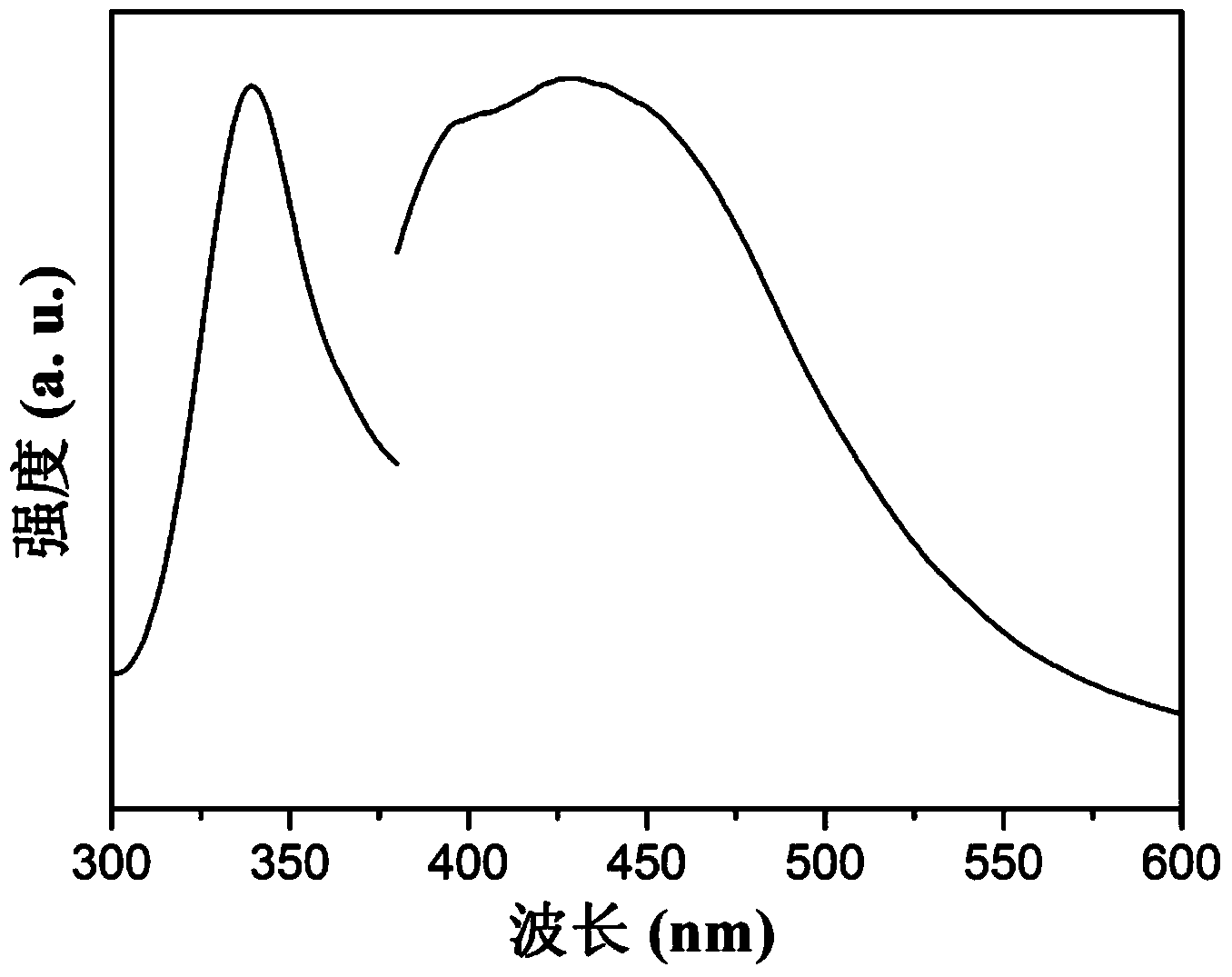

[0027] (1) Preparation of metal sulfide quantum dots: add metal chloride to oleic acid to prepare a mixed solution of oleic acid metal chloride with a concentration of 0.1-0.5mol / L, and stir magnetically at 90-170°C for 25-35min Finally, in the oleic acid metal chloride mixed solution, add a concentration of 0.2-0.6mol / L oleic acid solution dissolved with elemental sulfur, the volume of the oleic acid metal chloride mixed solution and the oleic acid solution dissolved with elemental sulfur The ratio is 2:1, and magnetically stirred at 150-320°C for 55-65min to obtain the crude product of metal sulfide quantum dots. Add absolute ethanol to the crude product of metal sulfide quantum dots to precipitate the metal sulfide quantum dots. Centrifuge at 8000-12000 rpm, wash the precipitate with absolute ethanol for more than three times, vacuum-dry the precipitate at 45-55°C to obtain metal sulfide quantum dots, dissolve the metal sulfide quantum dots in n-hexane, and The mass of the ...

Embodiment 1

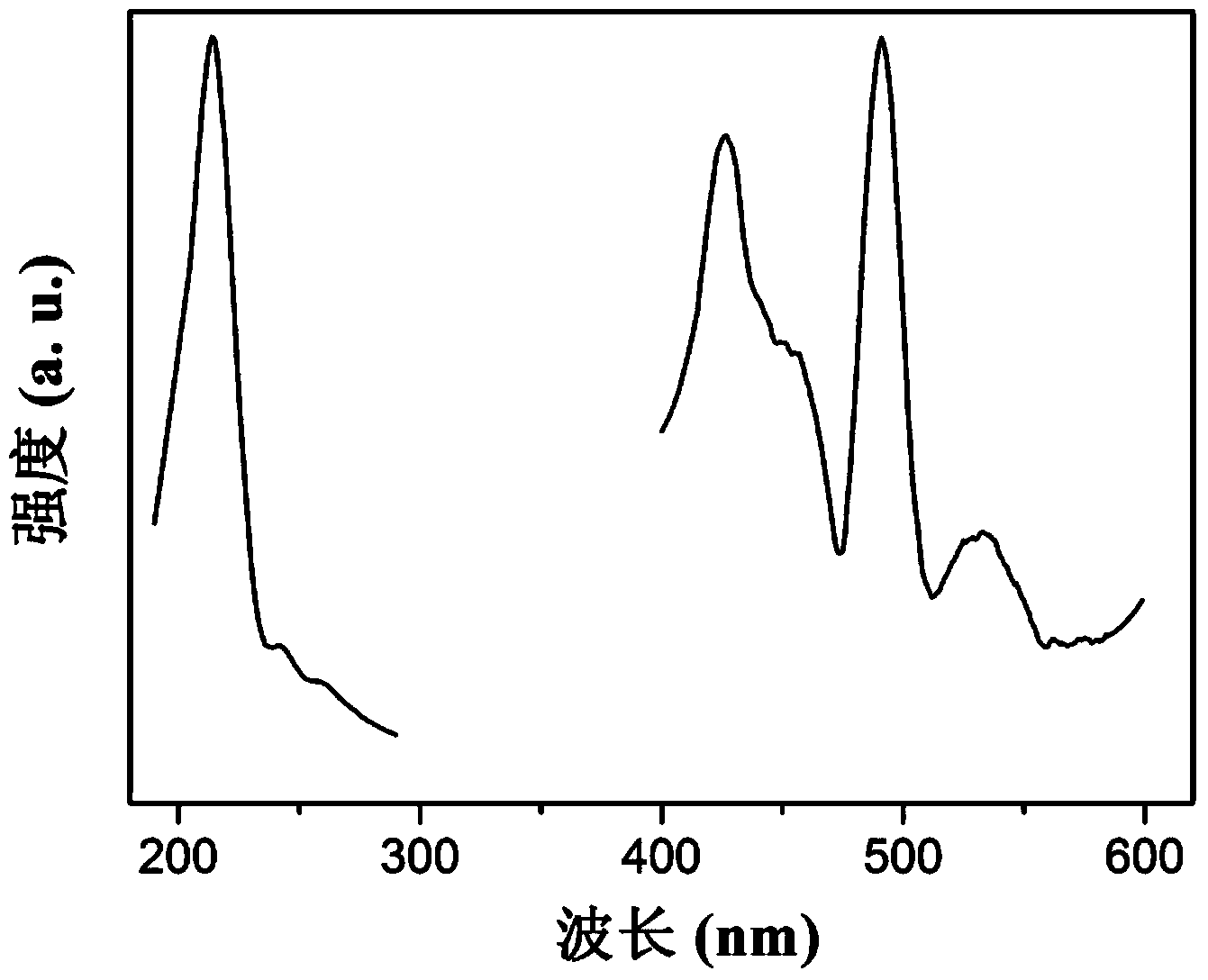

[0034] Add 2mmol of zinc chloride to 10mL of oleic acid to prepare a mixed solution of oleic acid metal chloride with a concentration of 0.2mol / L. After magnetic stirring at 170°C for 30min, add 5mL A 0.6mol / L oleic acid solution with elemental sulfur dissolved therein was magnetically stirred at 320°C for 60 minutes to obtain a crude product of metal sulfide quantum dots, and absolute ethanol was added to the crude product of metal sulfide quantum dots to make the metal sulfide quantum dots Spot the precipitate, centrifuge at 10000rpm, wash the precipitate with absolute ethanol for more than three times, and vacuum dry the precipitate at 50°C to obtain a white solid that is zinc sulfide quantum dots. Dissolve 4.85mg of zinc sulfide quantum dots in 9.7mL In n-hexane, zinc sulfide quantum dot n-hexane solution was obtained as the oil phase of the interface reaction; another nitric acid solution with a concentration of 0.05mol / L was prepared as the water phase of the interface re...

Embodiment 2

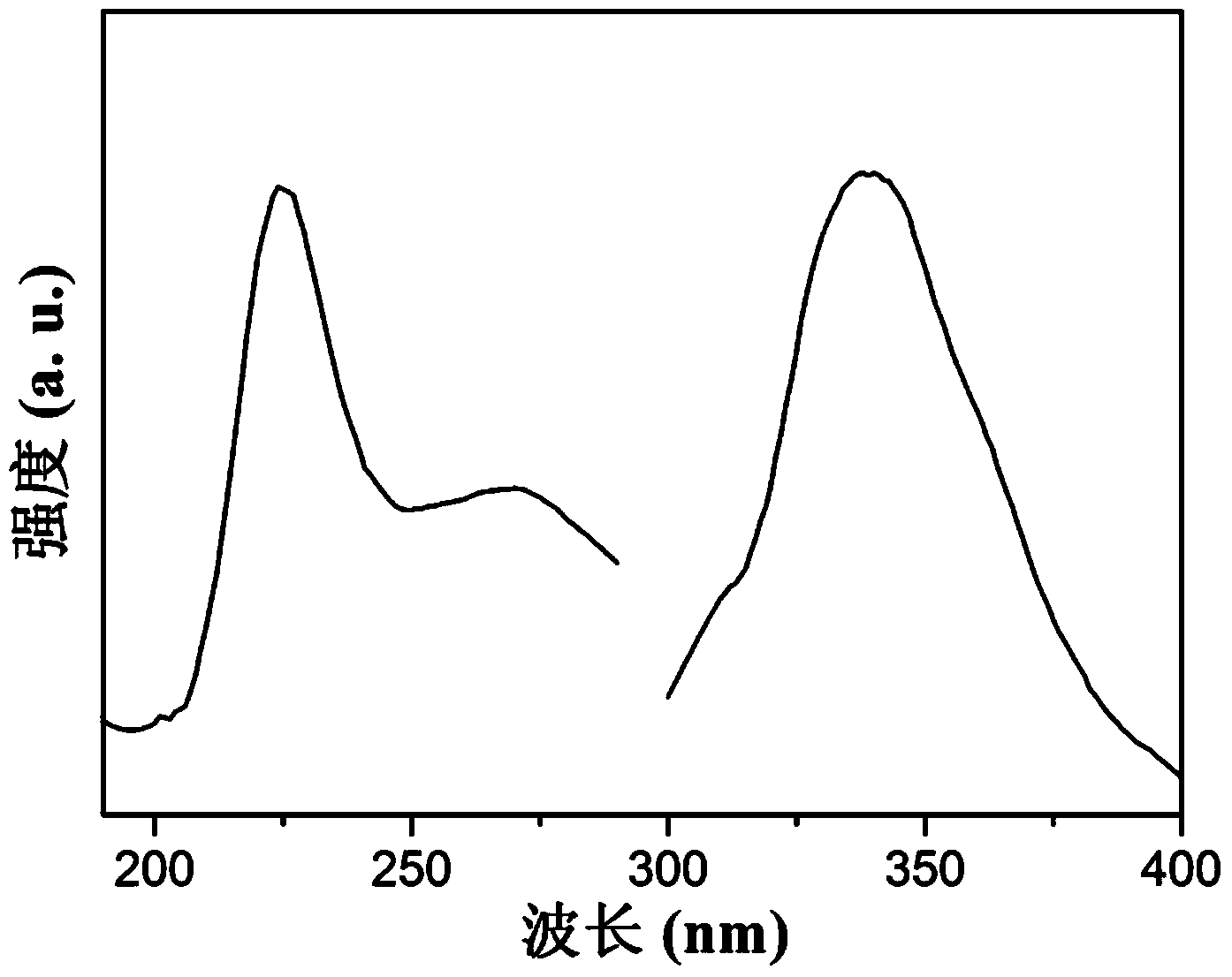

[0037] Add 5mmol of manganese chloride to 10mL of oleic acid to prepare a mixed solution of oleic acid metal chloride with a concentration of 0.5mol / L. After magnetically stirring at 120°C for 25min, add 5mL A 0.2mol / L oleic acid solution with elemental sulfur dissolved therein was magnetically stirred at 280°C for 55 minutes to obtain the crude product of metal sulfide quantum dots, and absolute ethanol was added to the crude product of metal sulfide quantum dots to make the metal sulfide quantum dots Spot the precipitate, centrifuge at 8000rpm, wash the precipitate with absolute ethanol for more than three times, and vacuum-dry the precipitate at 45°C to obtain a black solid that is manganese sulfide quantum dots. Dissolve 26.1mg of manganese sulfide quantum dots in 78.3mL In n-hexane, manganese sulfide quantum dot n-hexane solution was obtained as the oil phase of the interfacial reaction; another nitric acid solution with a concentration of 0.04mol / L was prepared as the aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com