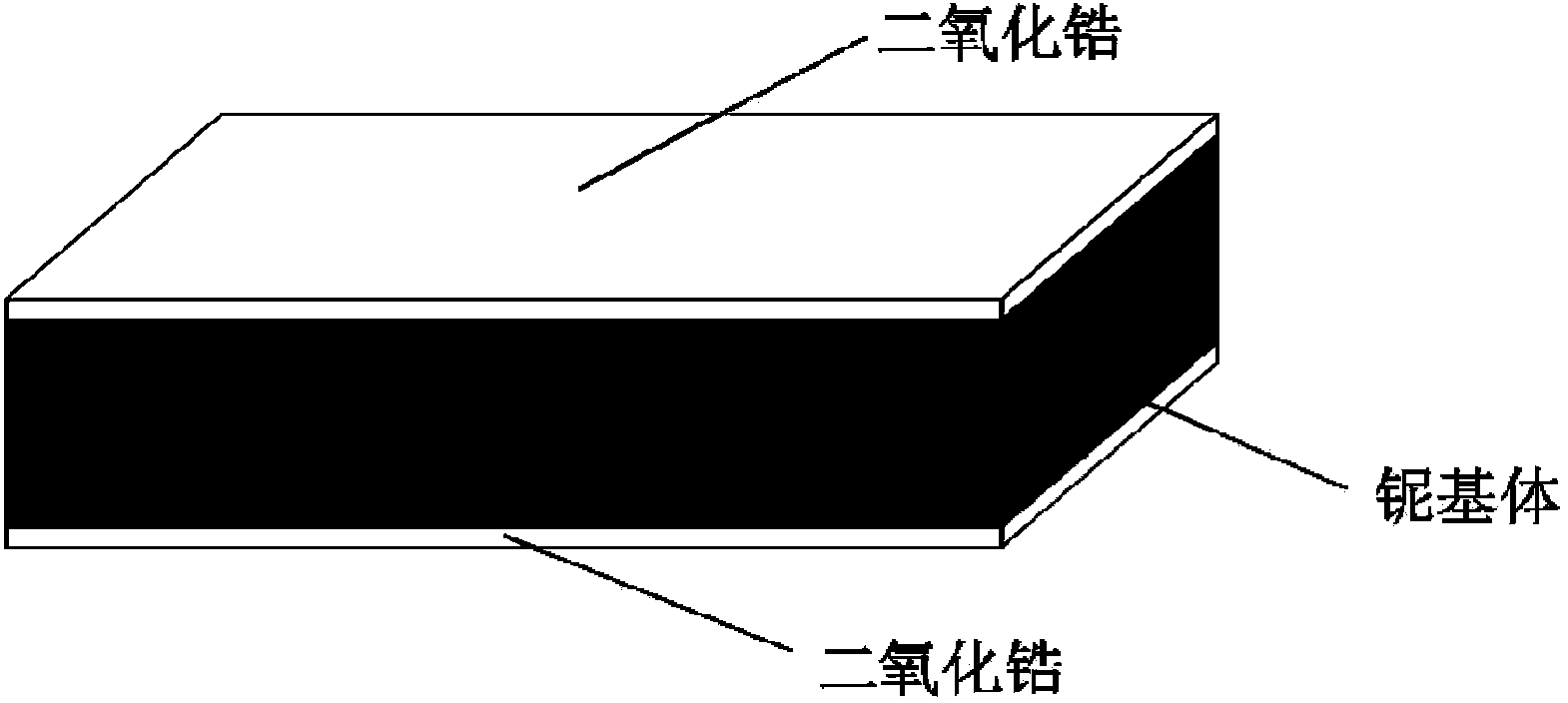

Preparation method for high-temperature-resistant laminated composite zirconium dioxide-niobium material

A technology of zirconium dioxide and high temperature resistant layer, which is applied in metal material coating process, coating, ion implantation plating, etc., and can solve problems such as easy warping and cracking, uneven sedimentation, and non-dense film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

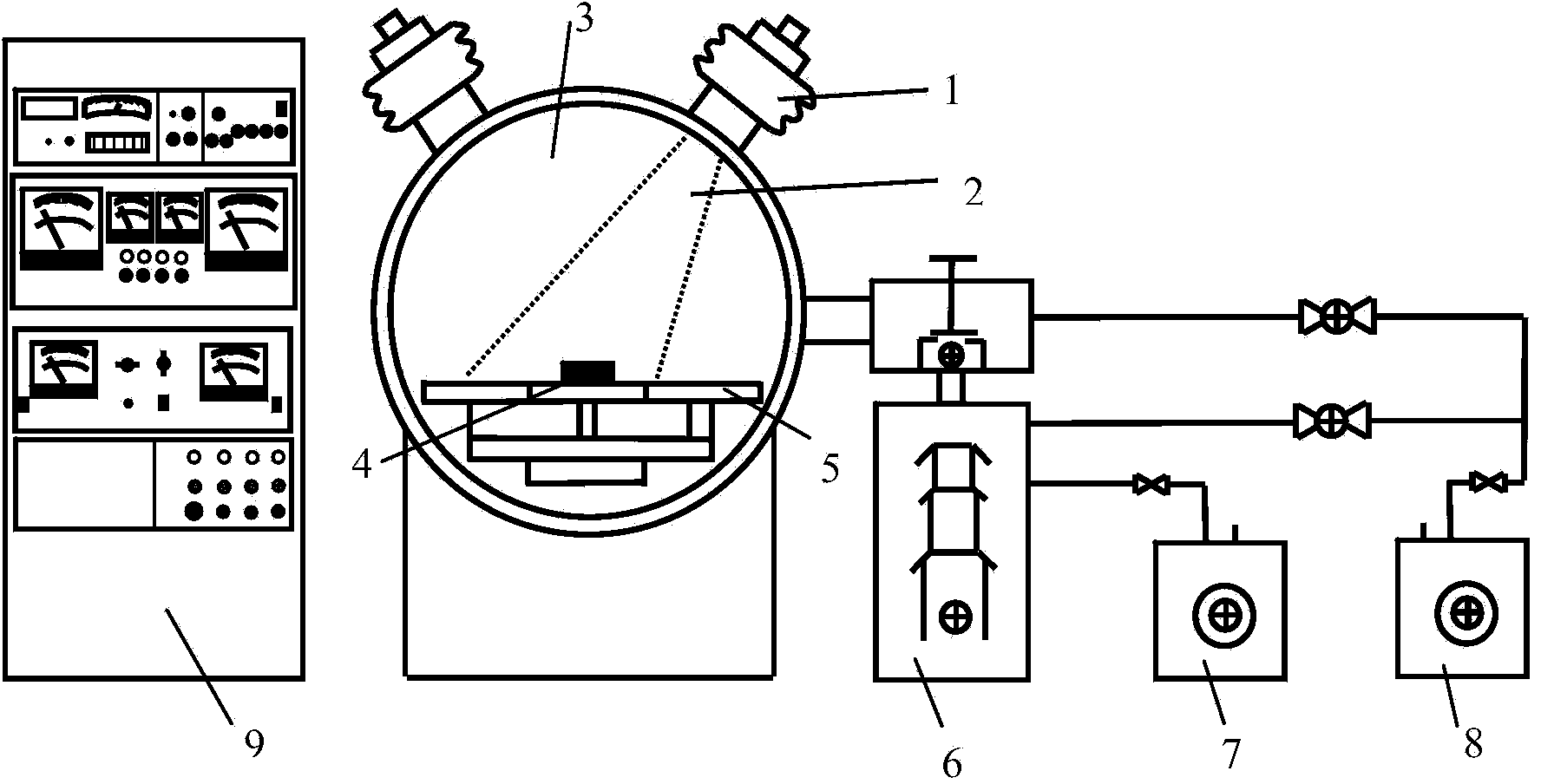

Method used

Image

Examples

Embodiment Construction

[0024] The following describes the detailed process of the present invention through the examples, and the examples are provided for the convenience of understanding, and are by no means limiting the present invention.

[0025] 1. Pretreatment. Cut the pure niobium plate into a test piece with a specification of 15mm×5mm×1mm, and polish it with 2000-grit sandpaper to remove part of the oxide film to make the surface of the test piece smooth. Then put the test piece in degreasing solution (50ml of 37% concentrated hydrochloric acid+50ml of 98% concentrated sulfuric acid+50ml of deionized water) for 5min to remove oil, and wash it with deionized water for 5 times after taking it out. Immerse the cleaned sample in 300ml of etching solution (100ml of 68% concentrated hydrochloric acid + 100ml of 40% hydrofluoric acid + 100ml of deionized water) and etch for 8min. (manufactured by Kunshan Hechuang Ultrasonic Instrument Co., Ltd., model Kh5200E) for ultrasonic cleaning. The ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com