A kind of electrochemical polishing method of palladium and its alloy

An electrochemical and palladium alloy technology, applied in the field of electrochemical treatment of metal surfaces, can solve problems such as scratches on deformed layers, low hardness of alloys, and scratches on the surface, so as to reduce waste liquid discharge, consume less raw materials, and have little environmental impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

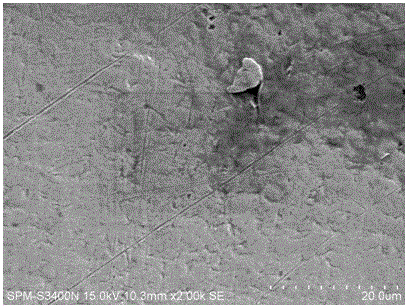

[0019] The electrochemical polishing method of this palladium, its concrete steps are as follows: at first take palladium as anode, carbon rod is cathode, with the organic acid that is 40% by mass percentage, the oxidizing acid of 10%, the organic alcohol of 10%, 1% The homogeneous mixed liquid composed of surfactant and the balance of water is the electrolyte, and the temperature of the electrolyte is 15°C, and the voltage is 10V. Polishing for 5 minutes, the palladium after electrochemical polishing can be taken out and cleaned to obtain a smoother surface. Ideal palladium, the surface topography of the metal before and after polishing is as follows figure 1 , 2 shown.

[0020] Wherein the organic acid is acetic acid; the oxidizing acid is perchloric acid; the organic alcohol is glycerol; the surfactant is nonylphenol polyoxyethylene ether; the power supply for controlling the voltage is a DC power supply; the above reagents are all analytically pure.

Embodiment 2

[0022] The electrochemical polishing method of this palladium-silver-copper alloy, its specific steps are as follows: first, take the palladium-silver-copper alloy (the mass percentage content of Pd is 35%) as the anode, the carbon rod as the cathode, and the organic acid with 60% by mass percentage , 5% of oxidizing acid, 10% of organic alcohol, 0.001% of surfactant and the balance of water are uniformly mixed liquid as electrolyte, and the temperature of the electrolyte is 30 ℃, and the voltage is 50V. Polishing 60min, The palladium-silver-copper alloy with an ideal surface can be obtained after the electrochemically polished palladium-silver-copper alloy is taken out and cleaned.

[0023] Among them, the organic acid is a mixed acid of formic acid and propionic acid with a volume ratio of 1:1; the oxidizing acid is nitric acid; the organic alcohol is a mixed alcohol of ethylene glycol, polyethylene glycol and polyvinyl alcohol with a volume ratio of 1:1:1; surface active Th...

Embodiment 3

[0025] The electrochemical polishing method of the palladium-silver-zinc alloy, its specific steps are as follows: first, the palladium-silver-zinc alloy (the mass percent content of Pd is 35%) is used as the anode, the carbon rod is the cathode, and the organic acid with a mass percent of 50% , 10% of oxidizing acid, 20% of organic alcohol, 0.01% of surfactant and the balance of water are uniformly mixed liquid as the electrolyte, and the temperature of the electrolyte is 15°C, and the voltage is 2V. Polishing for 40min, The palladium-silver-zinc alloy with an ideal surface can be obtained after the electrochemically polished palladium-silver-zinc alloy is taken out and cleaned.

[0026] Among them, the organic acid is oxalic acid; the oxidizing acid is a mixed acid of perchloric acid and nitric acid with a volume ratio of 1:1; the organic alcohol is polyvinyl alcohol; A mixture of oxyethylene ether and block polyoxyethylene-polyoxypropylene ether; the power supply for contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com