Method for manufacturing Grifola frondosa culture material from sunflower byproducts

The technology of cultivation material and frondosa, applied in the field of tree flower cultivation material, can solve the problems of traffic and civil aviation safety hazards, increase production cost, pollute the environment, etc., and achieve the effects of strong water retention, promotion of complementarity and good growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

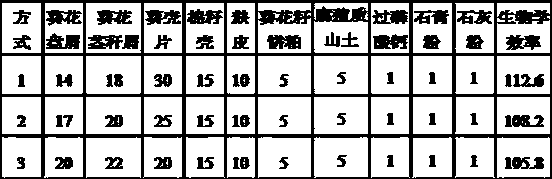

[0031] Method 1: The Grifola frondosa cultivation material in this example includes the following components and mass ratio: 14% sunflower disc chips, 18% sunflower stalk chips, 30% sunflower shell slices, 15% cottonseed hulls, 10% bran, sunflower 5% of seed cake, 5% of humus mountain soil, 1% of superphosphate, 1% of lime powder, and 1% of gypsum powder, all of which are the quality of dry matter, and the sum of the proportions is 100%.

[0032] Production Method:

[0033] ①Sunning material: Expose the raw material for 2 days before mixing the material, and use ultraviolet rays to kill some bacteria in the raw material;

[0034] ②Pre-wet: First, mix the sunflower disc chips, sunflower stalk chips, and sunflower shell slices evenly in a dry state, and then pre-wet with 1% lime aqueous solution (fully soaked);

[0035] ③ Stacking fermentation: Pile the wet material into a trapezoidal pile with a height of 1.2 m and a width of 3 m. The dry weight of each pile is controlled at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com