Quantum dot/polyurethane nano crystal complex and preparation method thereof as well as colorful conversion film

A color conversion film and nanocrystal technology, applied in the direction of photosensitive materials for opto-mechanical equipment, etc., can solve the problems of low color gamut, not bright and realistic colors, low light source utilization, etc., and achieve high luminous efficiency and saturation. High, pure color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

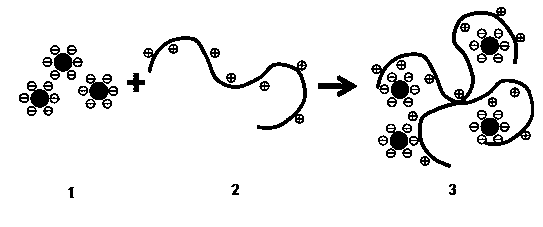

[0065] The quantum dot / polyurethane nanocrystal composite prepared by the above method increases the interaction between the quantum dot and the photoresist, overcomes the problems that the surface atoms of the quantum dot have high activity, is extremely unstable, and is easy to agglomerate. Better disperse in the photoresist to play the light-emitting properties of quantum dots. Therefore, the quantum dot / polyurethane nanocrystal composite can be used to prepare a color conversion film, and the preparation method of the color conversion film comprises the following steps:

[0066] i) Disperse the quantum dot / ionic polyurethane nanocrystal composite in the photoresist, and coat it on the transparent substrate of the prepared black matrix to form a layer of photoresist film with dispersed quantum dots; ii) through the mask film exposing the photoresist film; iii) developing the exposed photoresist film.

[0067] Among them, the main components of the so-called photoresist are...

Embodiment 1

[0072] Example 1: Preparation of quantum dot / polyurethane nanocrystal composite by solution blending method

[0073] Under a nitrogen atmosphere, 10mol 2,4-toluene diisocyanate, 6mol polyethylene glycol PEG400, and 5mol dibromoneopentyl glycol were prepared anyway to obtain a polyurethane containing bromine atoms in the side chain. Further, 5mol imidazole and side chains containing bromine atoms The polyurethane was quaternized to prepare imidazolium cationic polyurethane, which was dissolved in methyl ethyl ketone hot liquid to obtain a concentration of 0.1mg mL -1 Methyl ethyl ketone solution of ionic polyurethane, thioglycolic acid ligand-stabilized CdTe / ZnS quantum dots were dissolved in acetone solution to prepare 0.02mg mL -1 quantum dot nanocrystal solution. Under mechanical stirring, mix 10mL imidazolium cationic polyurethane solution with 10mL quantum dot solution, continue mechanical stirring for 0.5h, then add imidazolium cationic polyurethane precipitant methanol ...

Embodiment 2

[0076] Embodiment 2: Preparation of quantum dot / polyurethane nanocrystal composite by melt blending method

[0077] Under nitrogen atmosphere, 15mol 1,6-hexyl diisocyanate, 7mol unsaturated polyester diol 191#, 8mol 2,2-dimethylol propionic acid were prepared anyway to obtain polyurethane containing -COOH group in the side chain, and further , 8mol triethylamine reacted with polyurethane containing -COOH group in the side chain to produce an acid addition salt to prepare -COO-anionic polyurethane. Take 5g and heat it above the melting temperature. Under mechanical stirring, mix 1g of mercaptoethylene Disperse the amine-stabilized CdSe / CdS quantum dot powder into the ionic polyurethane in the molten state, continue mechanical stirring for 2 hours, and cool down to room temperature naturally to obtain the CdSe / CdS quantum dot / anionic polyurethane nanocrystal composite, which is placed in a desiccator Keep it in use (the whole composite process is completed under the protection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com