Large area multifunction graphene film preparation method

A graphene thin film, multifunctional technology, applied in the field of nanomaterials, can solve the problems of poor conductivity, difficult separation, low efficiency, etc., and achieve the effects of good flexibility and stability, simple preparation method, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of graphene oxide doped polyaniline

[0031] Weigh 0.5g of graphite oxide (200 mesh) into a beaker, add 100 mL of 1M HCl, and sonicate for 30 minutes, add 1g of aniline, and then sonicate for 2.0 hours, then stir the solution at room temperature for 30 minutes, and place it in In an ice-bath environment, slowly add 0.8 g of APS and 30 mL of 1M HCl solution, aniline reacts to form polyaniline, after the reaction is complete. Add 150 mL of ionized water to dilute the solution, and then put the solution in a funnel for suction filtration. After suction filtration, the polyaniline-doped graphene oxide obtained on the filter paper is dispersed in the aqueous solution, and the polyaniline-doped graphene oxide solution is Put it in a vacuum drying oven at 100°C for 10 h to obtain solid polyaniline-doped graphene oxide powder.

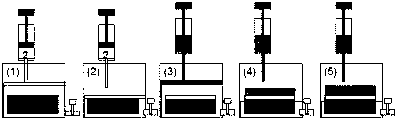

[0032] (2) Preparation of polyaniline-doped graphene oxide film

[0033] In a water tank with a valve, the valve at the bottom of th...

Embodiment 2

[0037] (1) Preparation of graphene oxide doped polyacetylene

[0038] According to the preparation method in Example 1, 1 g of aniline is changed into 2 g of acetylene, and the oxidant APS is changed into 1.2 g of FeCl 3 To prepare graphene oxide doped with polyacetylene.

[0039] (2) Preparation of graphene oxide films doped with polyacetylene and polyethylene oxide

[0040] According to the preparation method in Example 1, the glass sheet is replaced by flexible PET, and the inclination angle between the bottom of the tank and the bottom of the tank is 45 °, and the ethanol / ultrapure water mixed solution with a volume ratio of 1:8 is changed to 1: 6 acetone / ultrapure water mixture to prepare a single-layer flexible transparent graphene oxide film doped with polyacetylene. Then use a single layer of polyacetylene-doped flexible transparent graphene oxide film as a substrate, deposit polyethylene oxide-doped graphene oxide on it, and then dry it in an oven at 90°C to obtain...

Embodiment 3

[0044] (1) Preparation of graphene oxide doped polypropylene oxide

[0045] According to the preparation method in Example 1, 1 g of aniline was replaced with 2.3 g of propylene oxide to prepare graphene oxide doped with polypropylene oxide.

[0046] (2) Preparation of four-layer graphene oxide films doped with polypropylene oxide, polyacetylene, polythiophene and polyethylene succinate

[0047] According to the preparation method in Example 2, the glass substrate is replaced by a flexible FRP composite film, and the angle of inclination between the bottom of the tank and the bottom of the tank is 60°, and the ethanol / ultrapure water mixed solution with a volume ratio of 1:8 is changed to 1:9 N,N-dimethylformamide / ultrapure water mixture to prepare a single-layer large-area flexible transparent graphene oxide film doped with polypropylene oxide. The prepared single-layer doped polypropylene oxide large-area flexible transparent graphene oxide film was used as a substrate, on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com