Low-carbon energy-saving coating

An energy-saving coating and coating technology, which is applied in the direction of epoxy resin coating, reflection/signal coating, polyurea/polyurethane coating, etc., can solve the problems of conduction, coating surface heat loss, and amplifying coating phonon scattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

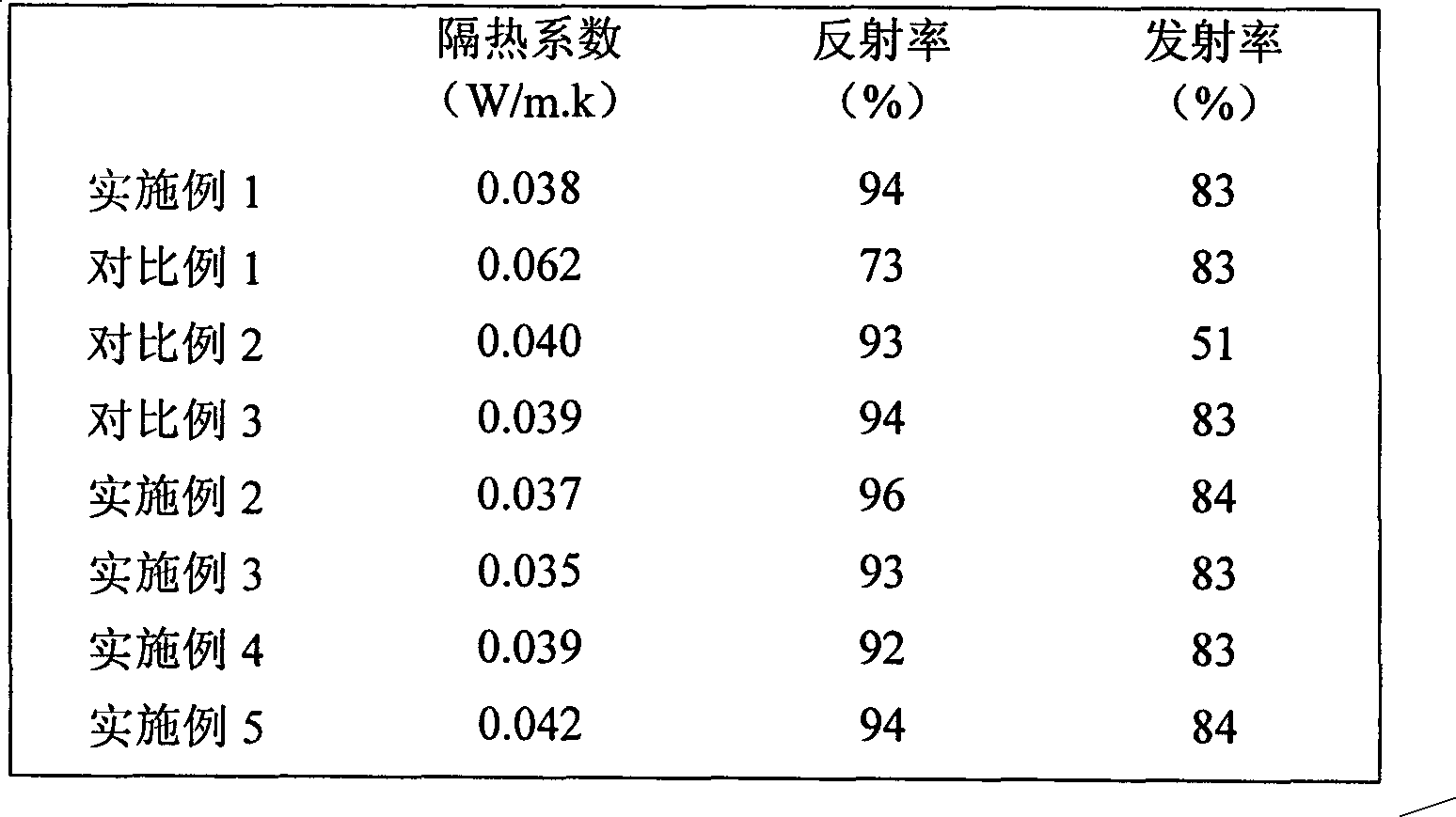

Examples

Embodiment 1 2

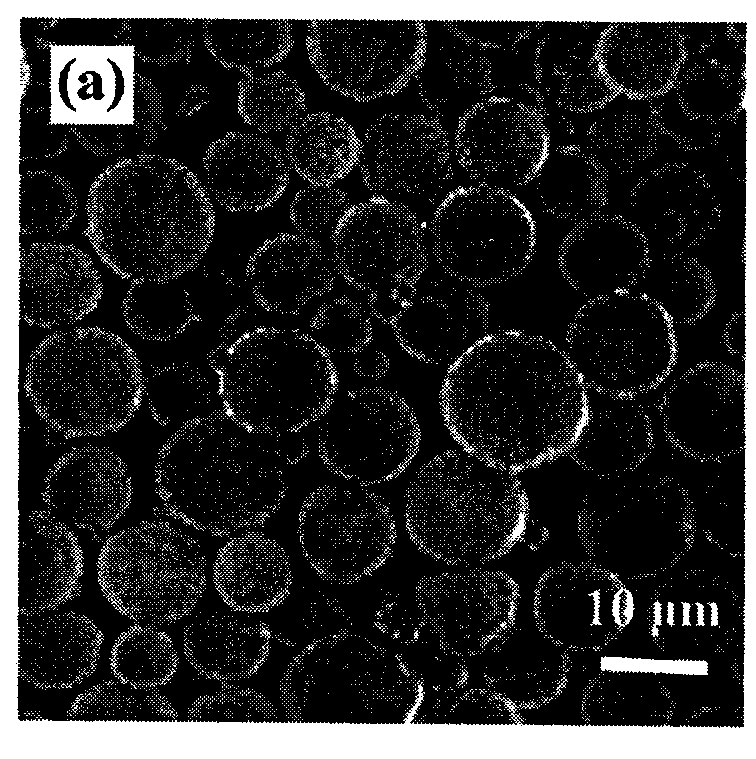

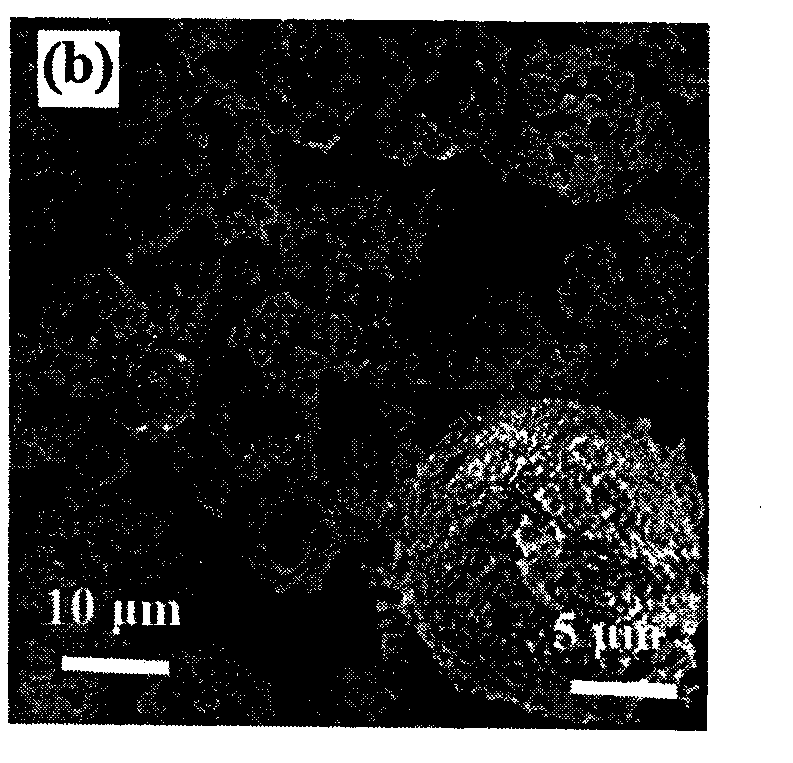

[0029] Example 1 Preparation of Titanium Dioxide Coated Hollow Silica Reflective Heat Ray Material

[0030] Add 5g of hollow silica powder to a mixed solution of 1ml of glacial acetic acid, 1ml of water, and 5ml of absolute ethanol under stirring conditions at 25°C, and mix thoroughly to obtain a uniformly dispersed mixed solution.

[0031] Dissolve 2.2ml of butyl titanate in 5ml of absolute ethanol within 10min at 25°C under the action of ultrasonic waves and stirring, and slowly add it dropwise to the above-mentioned hollow silica mixture, let it stand for 2h, and in the state of stirring Dry at 80°C for 1 hour to obtain a white gel. Place the above white gel in a temperature-programmed furnace, raise the temperature to 350°C at a rate of 2°C / min, and keep the temperature constant for 1 hour to obtain a nano-titanium dioxide-coated hollow bismuth. Composite material powder A1 of silicon oxide.

Embodiment 2

[0032] Example 2 Preparation of Tin Oxide-Indium Oxide Coated Hollow Silica Reflective Heat Ray Material

[0033] Use one of tin tetrachloride or tin sulfate to prepare 0.1-2mol / L solution A. Use one of indium nitrate, indium chloride and indium sulfate to prepare 0.1-2mol / L solution B. The two solutions of A and B are mixed, and the mixing ratio is between 1~10:10~1. Add hollow silicon dioxide to the mixed solution, stir to suspend it, add ammonium carbonate solution, adjust the solution pH to 5-9, control the temperature at 25°C, deposit the hydrolyzed product on the hollow silicon dioxide, filter and dry it at 500 °C to 700 °C for 1 hour heat treatment to obtain the tin oxide-indium oxide film-coated hollow silicon dioxide reflective heat ray material A2.

Embodiment 3

[0034] Example 3 Preparation of metal silver-coated hollow silica reflective heat ray material

[0035] In 100ml of silver nitrate aqueous solution with a concentration of 0.1-10%, add 10g of hollow silicon dioxide, add 5ml of 1% ammonia water, add 2ml of formaldehyde aqueous solution while stirring, and the reaction temperature is 25°C, so that the produced nano-silver particles are deposited on the hollow two A reflective film is formed on silicon oxide. After filtering and drying, the heat-ray-reflecting hollow silica material A3 coated with a silver layer is obtained.

[0036] Preparation method of infrared emitting powder

[0037]Using chemically pure ferric oxide, manganese dioxide, copper oxide, cobalt trioxide, and cordierite as raw materials, using the doping process between transition metal oxides to introduce dopants into the lattice and destroy its lattice Periodically, the crystal grains are finely distributed, and a variety of impurity levels are locally formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com