Treating and recycling process of acid wastewater generated in disperse dye production

A technology for disperse dyes and acidic wastewater, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problem of increasing treatment costs, increasing treatment steps, and the risk factor of liquid ammonia storage and transportation. Advanced problems, to achieve the effect of saving dosage, enhancing flocculation effect, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

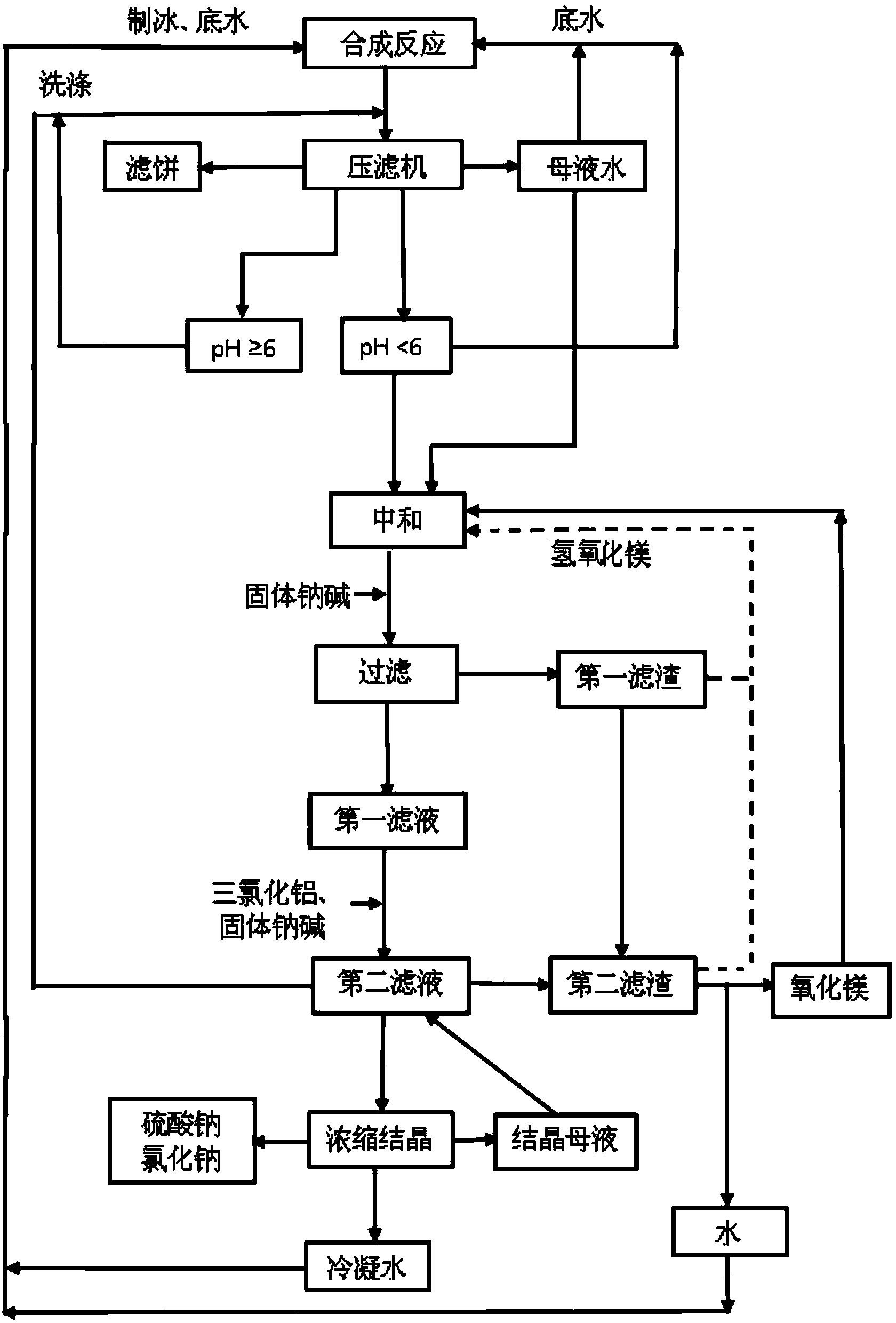

[0039] Such as figure 1 Shown:

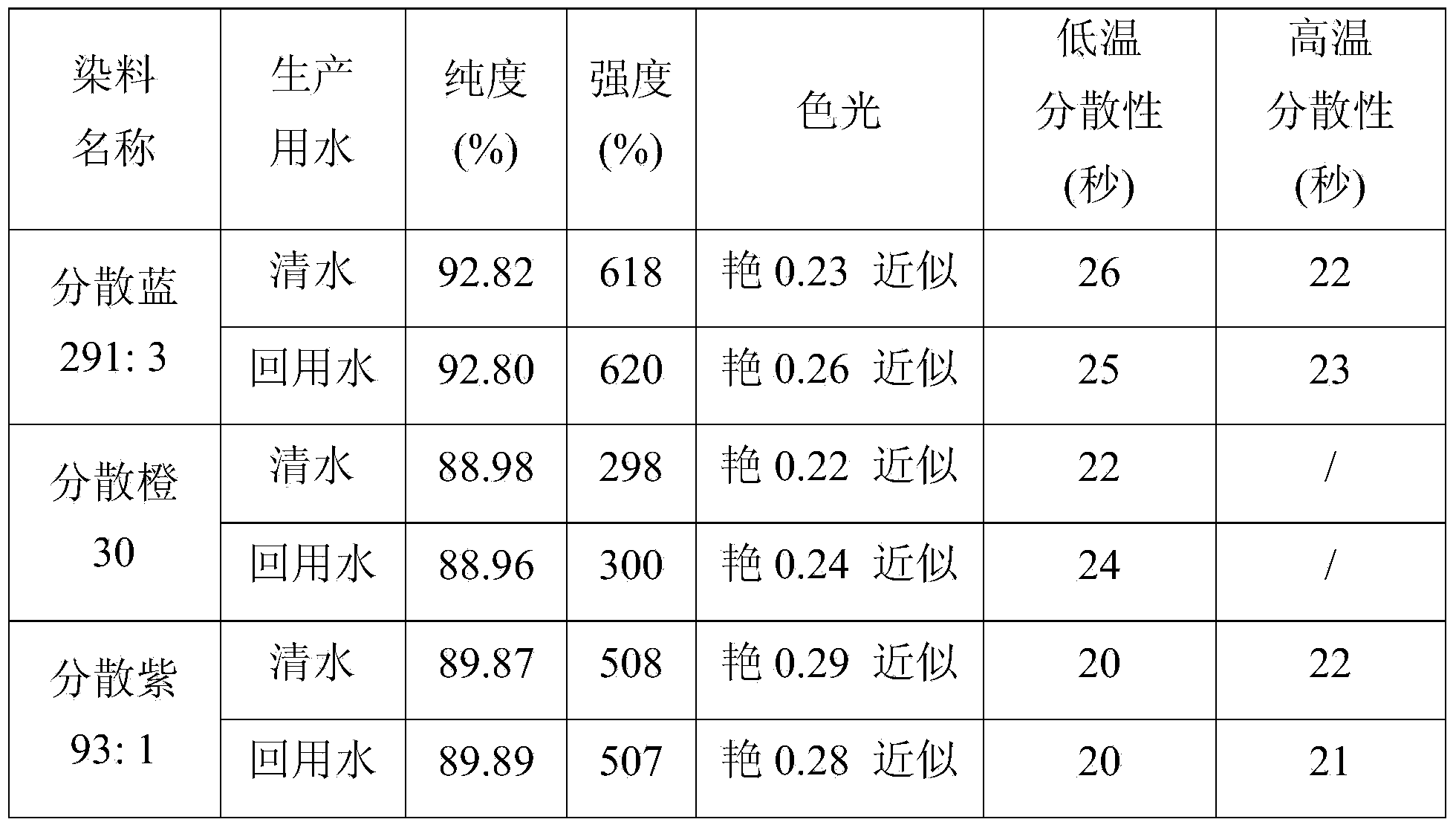

[0040] (1) Preparation of Disperse Blue 291:3 filter cake

[0041] Add 3800kg of nitrosyl sulfuric acid and 800kg of 98% sulfuric acid into the reactor, and add 2,4-dinitro-6-chloroaniline and 2,4-dinitro-6-bromoaniline with a mass ratio of 3:1 2000kg , stir to dissolve, control the temperature at 25-30°C for reaction, and detect the end point of the reaction with starch potassium iodide test paper to obtain a diazonium salt solution. Add 2600kg (dried) 2-methoxy-5-acetylamino-N,N-diallylaniline and 5kg Pingpingjia O-15 to 32 tons of sulfuric acid aqueous solution with an acid value of 8%, beat for 2 hours use. Slowly add the above-prepared diazonium salt solution into the prepared coupling solution, add 20 tons of ice, and carry out the coupling reaction at -5 ~ 0°C. After the reaction is completed, press filter, and the filtrate is 46 tons of mother liquor water. The filter cake is washed with water until the neutral disperse blue 291:3 f...

Embodiment 2

[0053] Preparation of Disperse Orange 30 filter cake

[0054] According to the method described in embodiment 1, the difference is:

[0055] In step (1), 2400kg of nitrosyl sulfuric acid is added to the reaction kettle, and then 2,6-dichloro-4-nitroaniline is added to react with 2000kg, and 2500kg of N-cyanoethyl-N-acetoxyethylaniline is added to the 25 tons of sulfuric acid aqueous solution with an acid value of 10%. With 15 tons of ice during coupling, filter cake is washed to neutrality with 130 tons of clear water; Obtain 32 tons of mother liquor water, 89 tons of acid washing water, 15 tons of neutral washing water;

[0056] In step (2), use Disperse Orange 30 instead of Disperse Blue 291:3;

[0057] In step (3), use 15 tons of neutral washing water instead of 15 tons of clear water to make ice for the coupling reaction, 15 tons of mother liquor water and 10 tons of acidic washing water instead of sulfuric acid aqueous solution as the bottom water for the coupling react...

Embodiment 3

[0059] (1) Preparation of Disperse Violet 93:1 filter cake

[0060] According to the method described in embodiment 1, the difference is:

[0061] In step (1), add 2100kg of nitrosyl sulfuric acid and 900kg of 98% sulfuric acid into the reactor, then add 2000kg of 2,4-dinitro-6-chloroaniline to react, and 2150kg of N,N-diethylm-acetyl Aminoaniline is added to 29 tons of sulfuric acid aqueous solution with an acid value of 5.5%. During coupling, use 18 tons of ice and 145 tons of clear water to wash the filter cake of Disperse Violet 93:1 to neutral; obtain 42 tons of mother liquor water, 125 tons of acidic washing water, and 18 tons of neutral washing water;

[0062] In step (2), use disperse violet 93:1 instead of disperse blue 291:3;

[0063] In step (3), use 18 tons of neutral washing water instead of 18 tons of clear water to make ice, 19 tons of mother liquor water and 10 tons of acidic washing water instead of sulfuric acid aqueous solution as bottom water for coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com