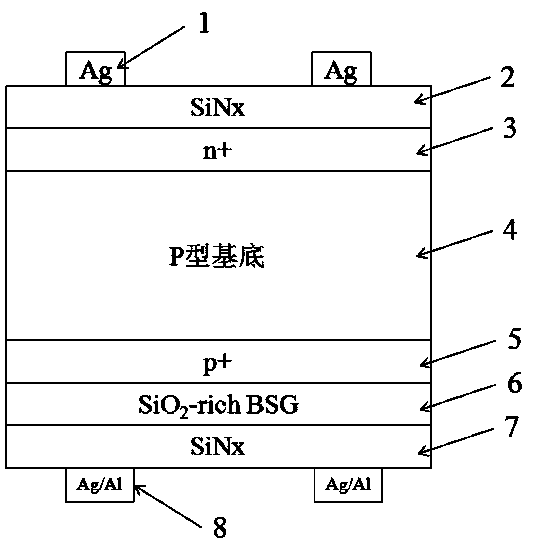

Double-face P-type crystalline silicon battery structure and manufacturing method thereof

A crystalline silicon cell, double-sided technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as unfavorable promotion and application of double-sided cells, lower production costs, unfavorable production efficiency, etc., to reduce production process costs and reduce density. , the effect of reducing the interface recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

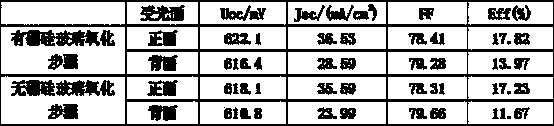

Embodiment 1

[0027] Adopt the method of the present invention to make a kind of double-sided P-type crystalline silicon battery structure, concrete steps are as follows:

[0028] (1) Czochralski monocrystalline P-type wafers are selected, with a resistivity of 1-5 ohm.cm. Both sides of the monocrystalline silicon wafers are cleaned and treated with positive pyramid texture to reduce the reflection of the final battery;

[0029] (2) Put the front surface of the above silicon wafer into a diffusion furnace for boron diffusion, using boron tribromide liquid source boron diffusion, the diffusion process is divided into deposition and advancement steps, the constant temperature zone is controlled at 900-960 during deposition and advancement The diffusion time is 30-60 minutes, and the placement method of the front surface veneer is to reduce the degree of boron diffusion on the front side of the silicon wafer as much as possible, and the boron diffusion resistance is controlled at 70-120 ohms / sq...

Embodiment 2

[0040] Adopt the method of the present invention to make a kind of double-sided P-type crystalline silicon battery structure, concrete steps are as follows:

[0041] (1) Czochralski monocrystalline P-type wafers are selected, with a resistivity of 1-3 ohm.cm. Both sides of the monocrystalline silicon wafers are cleaned and treated with positive pyramid texture to reduce the reflection of the final battery;

[0042] (2) Put the front surface of the above silicon wafer into a diffusion furnace for boron diffusion, using boron tribromide liquid source boron diffusion, the diffusion process is divided into deposition and advancement steps, the constant temperature zone is controlled at 900-960 during deposition and advancement The diffusion time is 30-60 minutes, and the placement method of the front surface veneer is to reduce the degree of boron diffusion on the front side of the silicon wafer as much as possible, and the boron diffusion resistance is controlled at 70-90 ohms / squ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com