Method for manufacturing nano silver wire

A technology of nano-silver wire and silver nitrate, which is applied in the direction of nanotechnology, can solve the problems of high synthesis cost, environmental pollution, harsh reaction conditions, etc., achieve good application and industrialization prospects, simple and easy-to-control preparation conditions, and low cost of process conditions low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

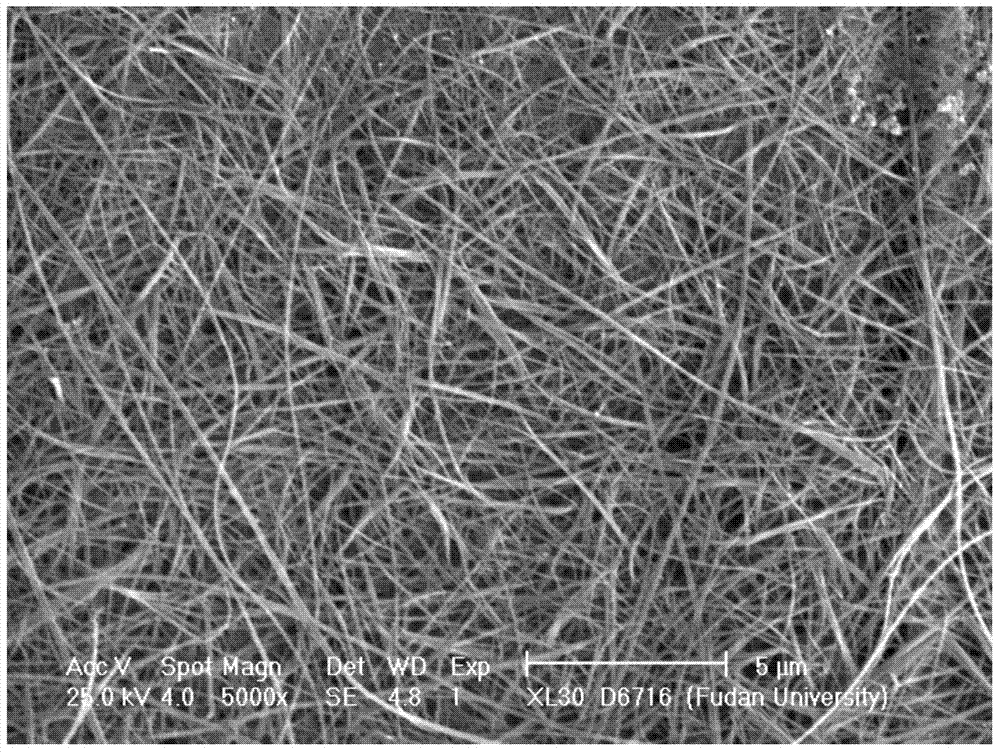

Embodiment 1

[0028] 1) The monocrystalline silicon used in this embodiment is a 1cm×1cm monocrystalline silicon wafer; the single crystal silicon wafer has a P-type 100 crystal surface, a resistivity of 3-8 ohms / cm, a thickness of 350nm, and single-sided polishing . Soak monocrystalline silicon in acetone for 5 minutes and wash with water;

[0029] 2) Place the monocrystalline silicon processed in step 1) into a 100mL centrifuge tube containing 40ml of silver nitrate aqueous solution with a concentration of 4g / L; the solid-to-liquid ratio of the monocrystalline silicon to the silver nitrate aqueous solution is 0.1 g / mL;

[0030] 3) adding hydrofluoric acid, capping and sealing the centrifuge tube, and sealing and reacting for 1 hour at an oil bath temperature of 50° C., wherein the volume ratio of the hydrofluoric acid to the silver nitrate aqueous solution in step 2) is 0.25;

[0031] 4) The reaction product in step 3) was taken out, washed with water and ultrasonically separated from t...

Embodiment 2

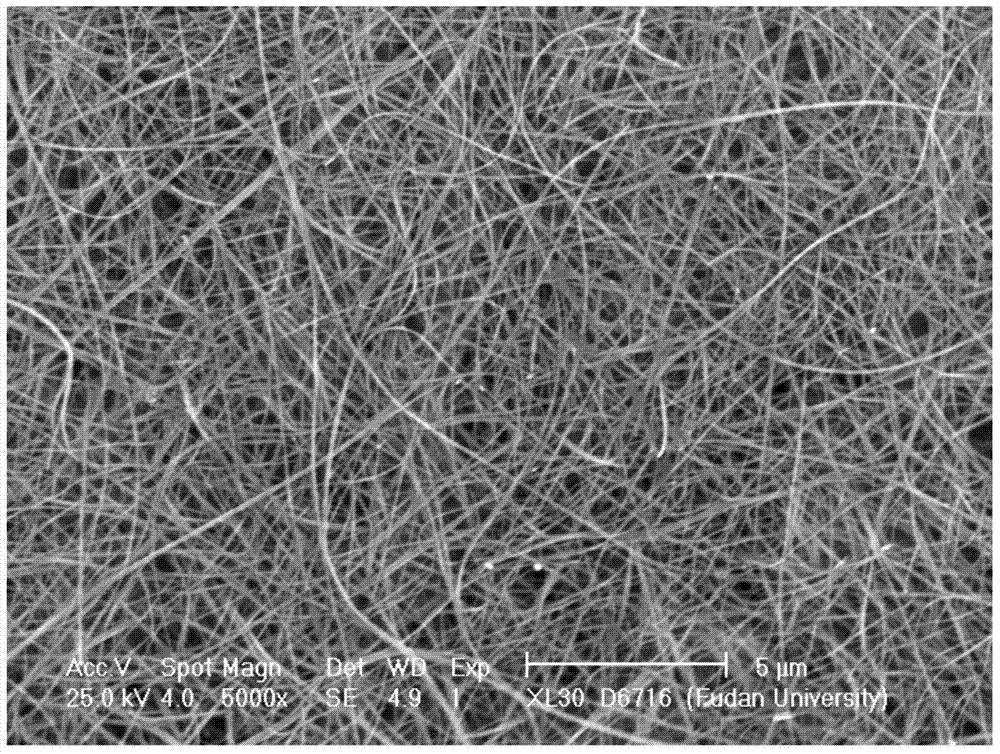

[0035] The single crystal silicon used in this embodiment is 40 mesh silicon powder.

[0036] 1) Soak 2g of silica fume in acetone for 5 minutes and wash with water;

[0037] 2) the silicon powder processed in step 1) is placed in the 100mL centrifuge tube that fills 40ml concentration and is the silver nitrate aqueous solution of 5g / L; The solid-liquid ratio of described monocrystalline silicon and described silver nitrate aqueous solution is 0.05g / mL;

[0038] 3) adding hydrofluoric acid, capping and sealing the centrifuge tube, and sealing and reacting for 2 hours at an oil bath temperature of 60° C., wherein the volume ratio of the hydrofluoric acid to the silver nitrate aqueous solution in step 2) is 0.2;

[0039] 4) The reaction product in step 3) was taken out, washed with water and ultrasonically separated from the silicon chip, and soaked in 6 wt% nitric acid aqueous solution for 2 minutes, then centrifuged to separate the solid and washed with water to obtain the p...

Embodiment 3

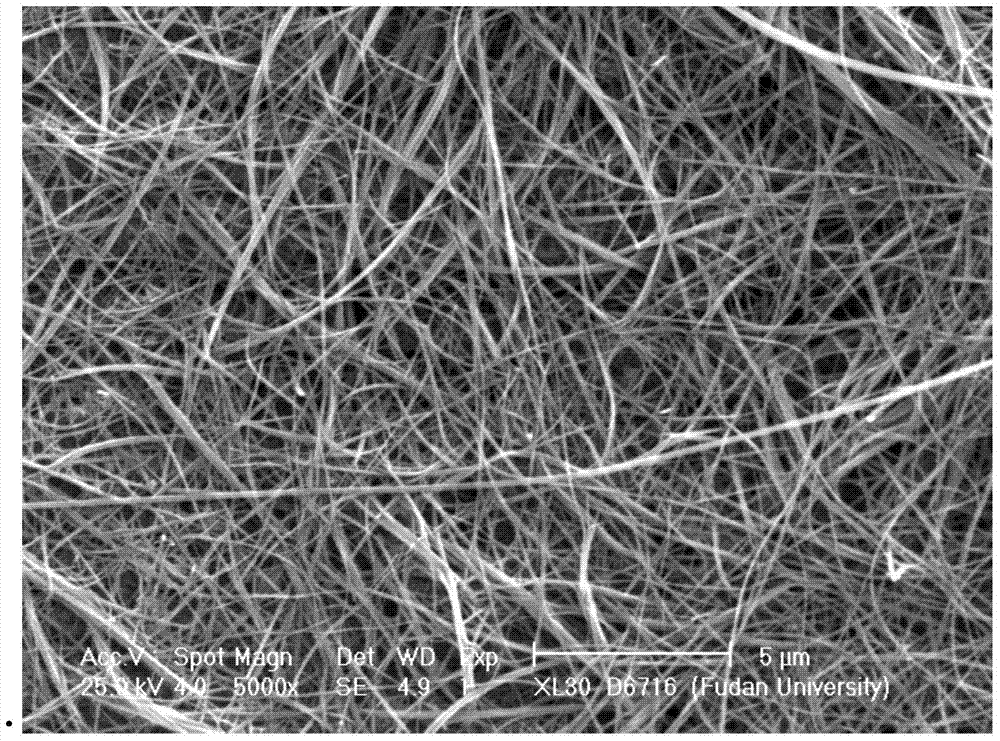

[0043] Experiment with the same method as Example 2, but change the silicon powder into 80 mesh.

[0044] The SEM picture of the silver nano wire obtained in the present embodiment is as image 3 shown.

[0045] The length of the nano-silver wire prepared in this example is: 5-50 μm, the diameter is 40-200 nm, and the product purity is more than 95%.

[0046] superior.

[0047] Using the silver nanowires prepared in Example 3 of the present invention, the conductive silver glue was prepared according to the preparation method of silver nanowire doped conductive silver glue disclosed in the domestic application number 2011100631768. The effect of the obtained conductive silver paste is shown in Table 1 and Table 2 below:

[0048] Among them, Table 1 is a comparison of the resistivity values of the conductive silver glue obtained after adding silver powder particles and adding the silver nanowires in Example 3 of the present invention. Table 2 is a comparison of the perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com