Catalyst for oxidizing and synthesizing dimethoxymethane by methyl alcohol as well as preparation method and application thereof

A technology for the oxidation of dimethoxymethane and methanol, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, physical/chemical process catalysts, etc., and can solve the problem of methylal selectivity of methanol conversion rate Problems that need to be improved, such as limiting the large-scale production and application of DMM, and the complicated DMM process, can achieve the effects of stable structure, long life and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

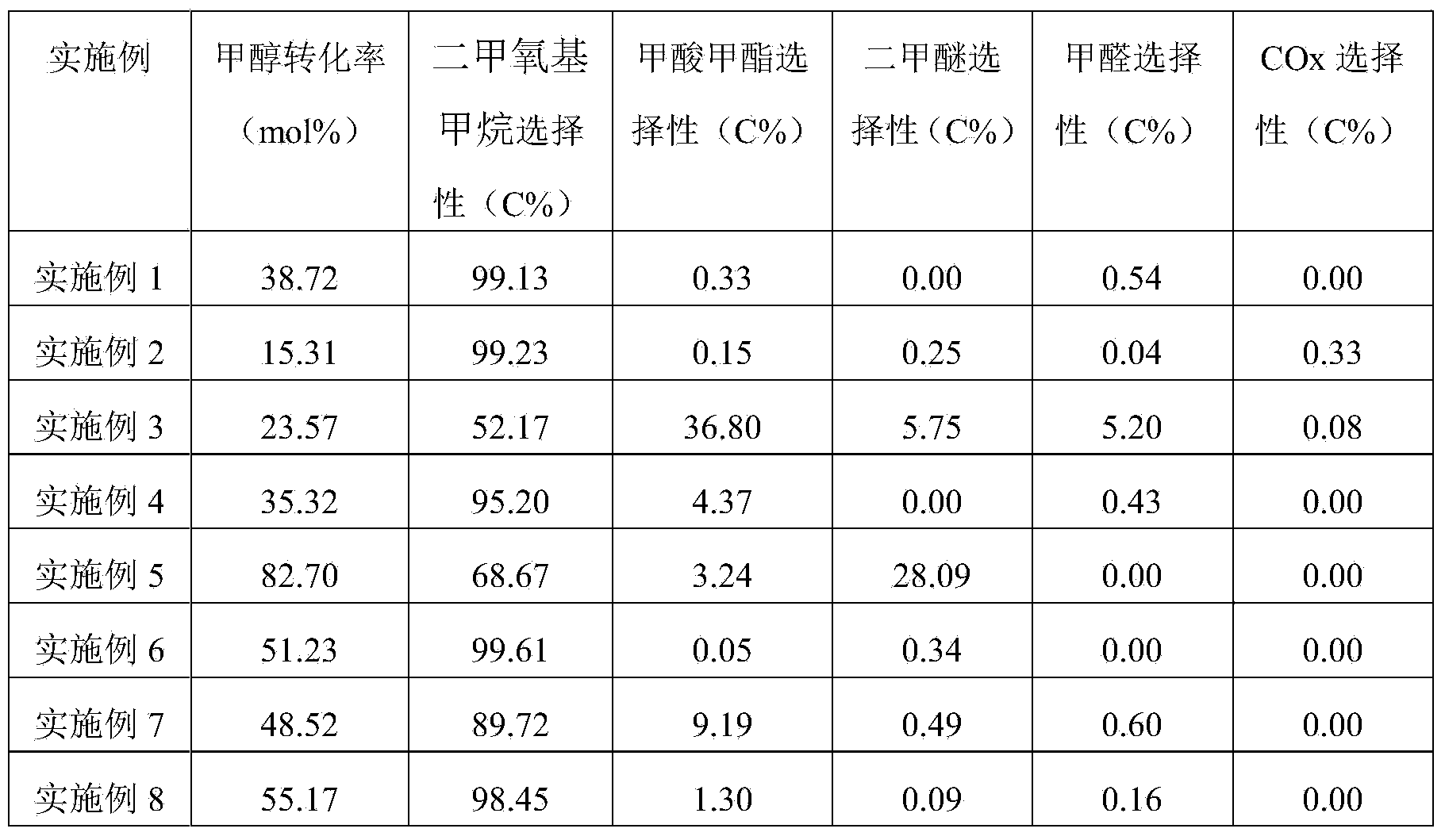

Examples

Embodiment 1

[0023] Catalyst preparation: Add 3.89g ammonium metavanadate, 8.36mL titanium tetrachloride, 15.86g zirconium oxychloride, 5.86mL malonic acid to 200mL, 12mol / L concentrated hydrochloric acid and 200mL deionized aqueous solution, heat and stir to dissolve, Obtain a transparent solution; the above solution was rapidly heated at 120°C in the air for 40min, then dried at 120°C for 24h, and then the product was roasted at 450°C for 12h to obtain a vanadium oxide content of 20%, a titanium oxide content of 40%, and a zirconium oxide content of 40%. Catalyst with a content of 40% is named 20VTi 0.40 Zr 0.40 .

[0024] Catalyst application: the catalyst in 7vol%O 2 / Ar atmosphere at 80ml.min -1 Activation at 400°C for 4 hours at a flow rate, then lowered to 80°C, the methanol liquid is preheated to 100°C by a preheater and vaporized to form a raw material gas with a mixed gas containing oxygen. The volume ratio of the raw material gas is N 2 :O 2 :CH 3 OH=84.15:9.35:6.50, the r...

Embodiment 2

[0026] Catalyst preparation: Add 4.68g sodium metavanadate, 6.69mL titanium sulfate, 12.24g cerium nitrate, 3.96mL oxalic acid to 200mL, 16mol / L concentrated nitric acid and 200mL deionized aqueous solution, heat and stir to dissolve to obtain a transparent solution; the above solution After rapidly heating at 100°C in the air for 30 minutes, drying at 130°C for 36 hours, and then roasting the product at 400°C for 13 hours, to obtain a product with a vanadium oxide content of 28%, a titanium oxide content of 37%, and a cerium oxide content of 35%. Catalyst, named 28VTi 0.37 Ce 0.35 .

[0027] Catalyst application: the catalyst in 10vol%O 2 / Ar atmosphere 70ml.min -1 Activation at 350°C for 10 hours at a flow rate, and then lowered to 100°C, the methanol liquid is preheated to 110°C by a preheater and vaporized to form a raw material gas with a mixed gas containing oxygen. The volume ratio composition of the raw gas is N 2 :O 2 :CH 3 OH=82.8:9.2:8.0, the raw material gas ...

Embodiment 3

[0029] Catalyst preparation: Add 5.41g potassium metavanadate, 6.69mL titanium isopropoxide, 22.31g aluminum nitrate, 14.55g citric acid to 250mL, 16mol / L concentrated nitric acid and 250mL deionized aqueous solution, heat and stir to dissolve to obtain a transparent solution After the above-mentioned solution was rapidly heated at 120° C. for 30 minutes in the air, it was dried at 120° C. for 15 hours, and then the resulting product was roasted at 400° C. for 12 hours to obtain a vanadium oxide content of 21%, a titanium oxide content of 47%, and an aluminum oxide content of 32% catalyst, named 21VTi 0.47 Al 0.32 .

[0030] Catalyst application: put the catalyst in 12vol%O 2 / Ar atmosphere 80ml.min -1 Activation at 400°C for 5 hours at a flow rate, and then lowered to 100°C, the methanol liquid is preheated to 120°C by a preheater and vaporized to form a raw material gas with a mixed gas containing oxygen. The volume ratio composition of the raw gas is N 2 :O 2 :CH 3 OH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com