Method for preparing epothilone B based on coupling of separation and fermentation of molecularly imprinted membrane

A technology of molecularly imprinted membrane and epothilone, which is applied in the field of fermentation engineering, to reduce feedback inhibition and product toxicity, reduce the cost of separation and purification, and facilitate post-processing and product refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation process of molecularly imprinted membrane in the present invention is: take polysulfone hollow fiber ultrafiltration membrane as base membrane, epothilone as template molecule, methyl methacrylate as functional monomer, ethylene glycol dimethacrylate as Cross-linking agent, methanol as solvent, azobisisobutyronitrile as initiator, prepared epothilone-imprinted hollow fiber composite membrane (molecularly imprinted membrane) by surface thermal polymerization.

[0032] The specific preparation process of the molecularly imprinted membrane is as follows: dissolve 10 mmol of epothilone in 50 mL of methanol-water mixed solution and let it stand for 30 min, add 40 mmol of α-methacrylamide and 200 mmol of pentaerythritol triacrylate, shake to dissolve for 10 min, and then add 60mg of azobisisobutyronitrile, ultrasonically degassed, repeatedly flushed with high-purity nitrogen for deoxygenation, and kept an inert environment. Using polysulfone hollow fiber ultraf...

Embodiment 1

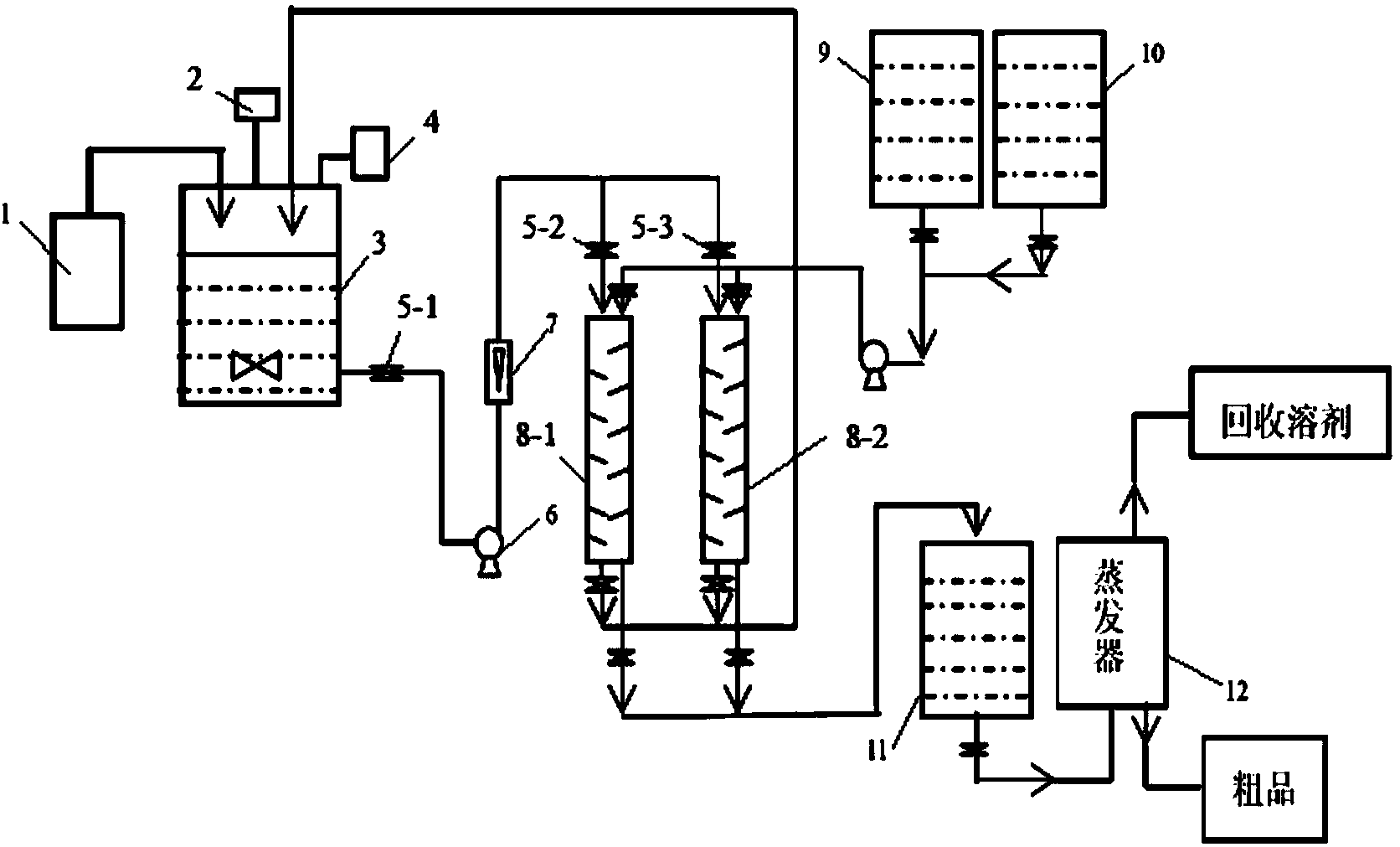

[0035] see figure 1 , a method for preparing epothilone B based on molecularly imprinted membrane separation and fermentation coupling, comprising the following steps:

[0036] (1) Pre-fermentation

[0037] Activation of strains: inoculate a preserved S. cellulosus ATCC25532 on the CNST medium for activation, and place a sterilized filter paper on the medium, and then place the CNST medium with the filter paper in a constant temperature incubator Cultivate at 30°C for 7 days; among them, the pH value of CNST medium is 7.2, and sterilize at 121°C for 30min; KNO in CNST medium 3 0.5g / L, Na 2 HPO 4 0.25g / L, MgSO 4 ·7H 2 O is 1g / L, EDTA-Fe 3+ The solution concentration is 1mL / L, the trace element solution concentration is 1mL / L, and the agar is 20g / L.

[0038] Seed culture: Use an inoculation loop to scrape the yellow colony that degraded the filter paper from the CNST medium, inoculate it into a seed bottle containing the seed medium, place it on a roving shaker (200r / min)...

Embodiment 2

[0044] A method for preparing epothilone B based on molecularly imprinted membrane separation and fermentation coupling, comprising the following steps:

[0045] (1) early stage fermentation: with embodiment 1.

[0046] (2) Fermentation culture: the seed culture liquid is inoculated in the fermentor of 5 liters according to the ratio of inoculating 8mL per 100mL, the liquid filling amount of the fermentation medium in the fermenter is 70%, the culture temperature is 30 ℃, and the stirring speed is 130r / min; the ventilation volume is 2.5L / min.

[0047] (3) Molecularly imprinted membrane filtration to remove epothilone B: S. cellulosus was fermented and cultivated in the fermenter 3. After 96 hours of fermentation and cultivation, the first valve 5-1 and the second valve 5-2 were opened to pass through the peristaltic pump 6 And flow meter 7 makes the fermented liquid in the fermentor 3 continuously enter in the first filtering device 8-1, filters and removes epothilone B, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com