Preparation method of cyclohexanone and cyclohexanol

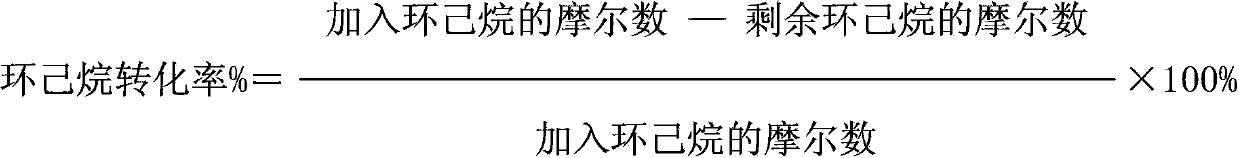

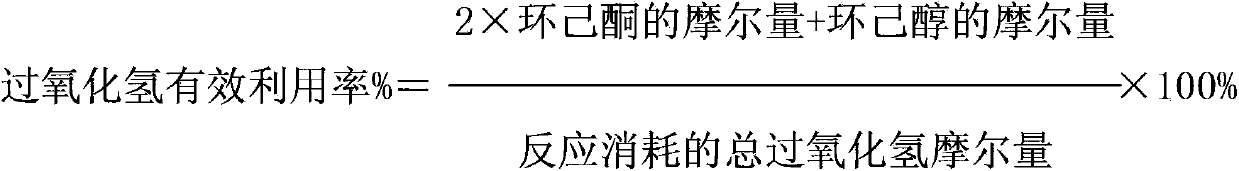

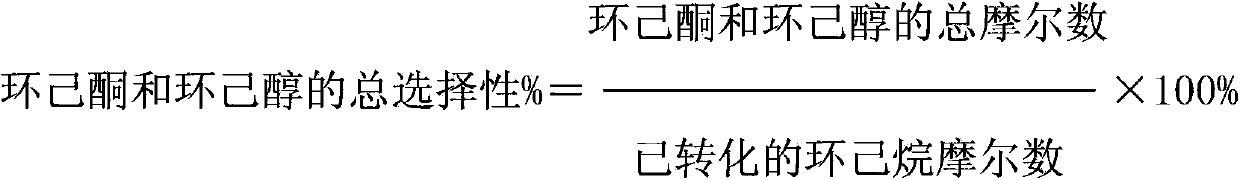

A technology of cyclohexanol and cyclohexanone, which is applied in the field of preparation of cyclohexanone and cyclohexanol, can solve the problem of large circulation amount of cyclohexane, low conversion rate of cyclohexane, and total selection of cyclohexanone and cyclohexanol. It can reduce the energy consumption and cost of separation, increase the selectivity of products, and improve the effective utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0008] The preparation method of cyclohexanone and cyclohexanol provided by the present invention is characterized in that it comprises cyclohexane and oxidant hydrogen peroxide at a temperature of 30-120°C and a pressure of 0.01-1.5MPa in the presence of a titanium-silicon molecular sieve catalyst. Under the condition that the molar ratio of cyclohexane is 1:0.1~10, cyclohexane is contacted with oxidant hydrogen peroxide to obtain cyclohexanone and cyclohexanol, and the azeotrope of unconverted cyclohexane and water is distilled off and separated, The step in which the cyclohexane is recycled, the water includes the water brought in by the oxidant hydrogen peroxide and the water generated by the contact process between the cyclohexane and the oxidant hydrogen peroxide, the water brought in by the oxidant hydrogen peroxide and the cyclohexane The total amount of water generated in the contact process with oxidant hydrogen peroxide is 1 part, and the water taken out by the azeot...

Embodiment 1

[0039] This example illustrates the method provided by the invention.

[0040] Put cyclohexane, hydrogen peroxide, solvent and microsphere catalyst according to the initial molar ratio of cyclohexane to hydrogen peroxide is 1:2, the molar ratio of solvent methanol to cyclohexane is 20:1, at a temperature of 80°C And the reaction is carried out in the slurry bed under the pressure of 0.10MPa, the feed rate of regulating cyclohexane and hydrogen peroxide, and if necessary, the heating power of the reaction is adjusted step by step (the process steps controlled by the remaining embodiments are similar, and will not be repeated. ), make cyclohexane and water form an azeotrope and distill it out, and make the ratio of the water brought out by the azeotrope to the water brought in by the oxidant and generated be 0.6:1, the ring brought out by the azeotrope The ratio of hexane to unreacted cyclohexane is 0.5:1; then the distilled azeotrope is statically separated into cyclohexane and...

Embodiment 2

[0042] This example illustrates the method provided by the invention.

[0043] Cyclohexane, hydrogen peroxide, solvent and microsphere catalyst are prepared according to the molar ratio of cyclohexane to hydrogen peroxide is 1:1, the molar ratio of solvent acetone to cyclohexane is 50:1, at a temperature of 40°C and The reaction is carried out in the slurry bed under the pressure of 0.04MPa, and the azeotrope of cyclohexane and water is distilled out at the same time, and the ratio of the water brought out by the azeotrope to the water brought in and produced by the oxidant is 0.5:1 , the ratio of cyclohexane brought out by the azeotrope to unreacted cyclohexane is 0.3:1; then the distilled azeotrope is statically separated into cyclohexane and water, and the separated cyclohexane Return to the slurry bed reactor for continuous reaction, while the separated water is discharged directly. The results of the reaction for 2 hours were as follows: the conversion rate of cyclohexan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com