Crop straw decomposing inoculant and using method and effect thereof

A technology of crop straw and decomposing bacteria agent, which is applied in the direction of botany equipment and methods, methods based on microorganisms, biochemical equipment and methods, etc., and can solve the problem of insufficient utilization of straw resources, affecting plowing and rotary tillage operations, straw Deal with problems such as short time to achieve the effect of improving crop quality, increasing nutrient conversion rate, and reducing pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

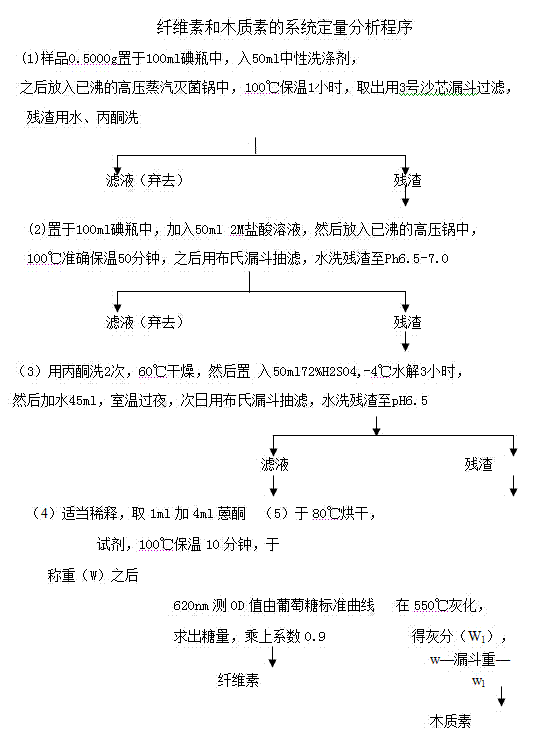

Method used

Image

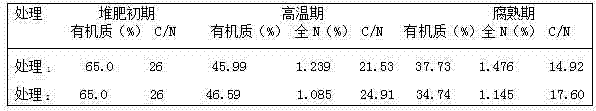

Examples

Embodiment 1

[0036] Preparation of media and strains

[0037] 1. Preparation of culture medium

[0038] 1. Potato and dextrose agar medium (PDA)

[0039] Take 200 grams of peeled potatoes, cut them into small pieces, add 1000ml of water and boil for 30 minutes, filter out the potato pieces, make up the filtrate to 1000ml, add 20 grams of glucose, 15 grams of agar, dissolve and subpackage, sterilize for 30 minutes in 15 pounds , the pH is natural, and no agar is added when preparing the liquid medium.

[0040] 2. Nutrient gravy agar

[0041] It consists of 5g of peptone, 5g of sodium chloride, 3g of beef extract and 1000ml of distilled water. pH7.0 (add 15-20g of agar to the solid medium).

[0042] 3. Potassium bacteria medium

[0043] Yeast Extract 0.4g, Mannitol 10.0g, K 2 HPO 4 0.5g, MgSO 4 7H 2 O 0.2g, FeCl 3 0.005g, CaCO 3 1.0g, 1000.0ml distilled water, pH7.0-7.2, add 15g agar when preparing solid medium.

[0044] 4. Solid fermentation medium

[0045] 80g wheat bran,...

Embodiment 2

[0058] Embodiment 2: (parts by weight)

[0059] A crop straw decomposing bacterial agent, prepared as follows (by weight):

[0060] Table 1 Composition of crop straw decomposing bacteria agent

[0061] name Phaneroderma chrysosporium Trichoderma chrysogreen Bacillus subtilis Bacillus peptiformis (1) 0.5 2.0 1.0 2.0 (2) 1.0 1.5 2.0 1.5 (3) 1.5 1.0 1.5 1.0 (4) 2.0 0.5 0.5 0.5

[0062] The number of effective viable bacteria is 6×10 8 piece / g;

Embodiment 3

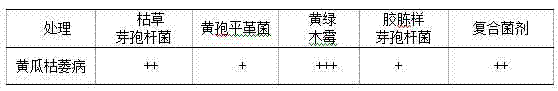

[0064] Mutual antagonism experiment between strains

[0065] The activated Phaneroderma chrysosporium, Trichoderma chrysogenum, Bacillus subtilis and Bacillus peptone-like were subjected to the mutual antagonism experiment between strains, and they were combined in pairs, divided into 12 combinations in total, and each combination was repeated three times.

[0066] The steel ring method was used to carry out the antibacterial test, and the strain was cultured in the corresponding medium for 3-5 days (190r / min, 28°C) to make a fermentation broth. Take 0.1mL of the fermentation broth of one of the bacteria (A) and spread it on a PDA plate, then place two pre-sterilized steel circles on the solid medium of each plate, and then add 0.25mL to each steel circle For the fermentation broth of any bacteria (B) other than bacteria A, each treatment was repeated three times, and the plate only inoculated with bacteria A was used as a control. Incubate at 28°C and observe the antibacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com