A polymer dielectric with low dielectric constant and low loss and preparation method thereof

A low dielectric constant, polymer technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., to improve electrical insulation, increase thermal conductivity, reduce low dielectric constant and loss value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

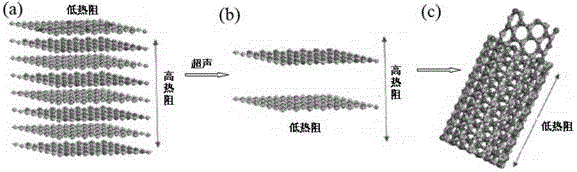

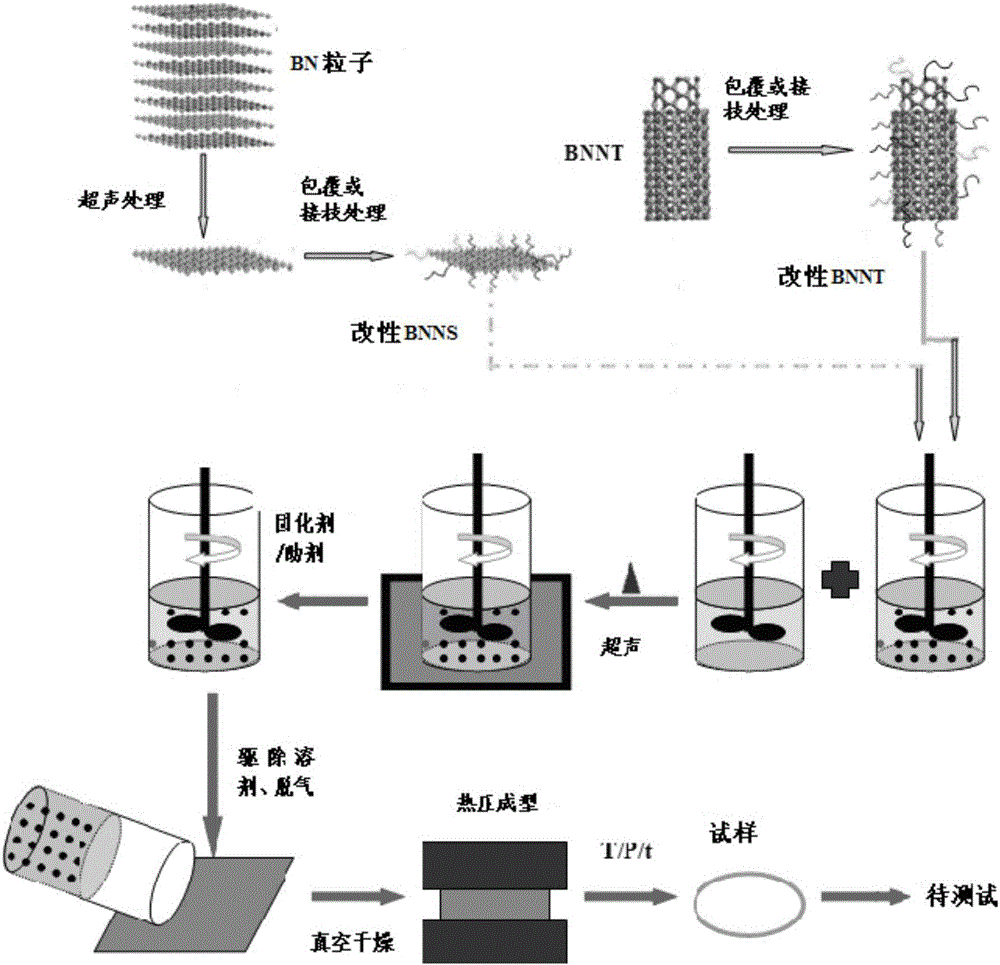

[0028] see image 3 , a method for preparing a polymer dielectric with low dielectric constant and low loss, comprising the steps of:

[0029] 1) Surface modification of BNNTs:

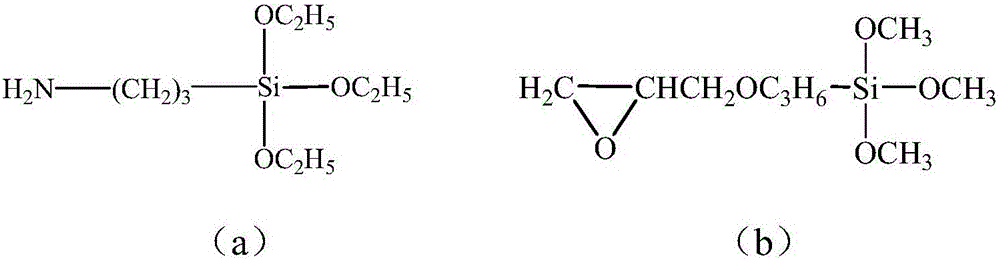

[0030]Put 10g of BNNTs into a hydrogen peroxide solution with a mass concentration of 65%, soak it under ultrasonic for about 30-32h, filter to remove impurities, wash it with deionized water until the pH value is about 7 and dry it, then add it to pure toluene, and Add KH-550 silane coupling agent (structural formula see figure 2 ), reflux and stir at 85-95°C for 10-12h, then continue to reflux at 110-120°C for 4-5h; finally carry out high-speed centrifugation and put the solid obtained by centrifugation into a vacuum oven and dry at 80-100°C After 8-12 hours, the surface-modified BNNTs are obtained and are ready for use.

[0031] 2) Surface modification of BNNSs particles

[0032] Take 25g of BNNSs into a nitric acid solution with a mass concentration of 50%, soak for about 40-45 hours, filter ...

Embodiment 1

[0037] A polymer dielectric with low dielectric constant and low loss, comprising 50% epoxy resin system and 50% hybrid nano boron nitride particles by mass percentage; wherein the hybrid nano boron nitride particles are boron nitride A mixture of nanotubes (BNNTs) and boron nitride nanosheets (BNNSs); the epoxy resin system is composed of 100phr epoxy resin E-51 and 85phr of hexahydromethylphthalic anhydride and 1phr of benzyl di A mixture of methylamines.

[0038] The diameter of boron nitride nanotubes (BNNTs) is about 70-80 nm, and the tube length is about 15-20 μm; the diameter of boron nitride nanosheets (BNNSs) is about 3-5 μm, and the thickness is about 40-60 nm. The optimal weight ratio between BNNTs and BNNSs is 0.3:1.

[0039] A method for preparing a polymer dielectric with low dielectric constant and low loss, comprising the steps of:

[0040] 1) Surface modification of BNNTs:

[0041] Put BNNTs in a hydrogen peroxide solution with a mass concentration of 65%, ...

Embodiment 2

[0047] A polymer dielectric with low dielectric constant and low loss, comprising 60% epoxy resin system and 40% hybrid nano-boron nitride particles by mass percentage; wherein the hybrid nano-boron nitride particles are boron nitride A mixture of nanotubes (BNNTs) and boron nitride nanosheets (BNNSs); the epoxy resin system is composed of 100phr epoxy resin E-51 and 85phr of hexahydromethylphthalic anhydride and 1phr of benzyl di A mixture of methylamines.

[0048] The diameter of boron nitride nanotubes (BNNTs) is about 70-80 nm, and the tube length is about 15-20 μm; the diameter of boron nitride nanosheets (BNNSs) is about 3-5 μm, and the thickness is about 40-60 nm. The optimal weight ratio between BNNTs and BNNSs is 0.4:1.

[0049] A method for preparing a polymer dielectric with low dielectric constant and low loss, comprising the steps of:

[0050] 1) Surface modification of BNNTs:

[0051] Put the BNNTs in a hydrogen peroxide solution with a mass concentration of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com