Porous phosphor-nitrogen-codoped carbon material and preparation method thereof

A porous carbon material and carbon material technology, applied in the field of carbon materials, can solve problems such as low specific surface area and performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A. Dissolve 0.20g of triphenylphosphine in 2ml of aniline, stir to dissolve evenly, add to 10mL of 2mol / L hydrochloric acid solvent, stir and mix evenly, then add 5g of silicon dioxide nanosphere silicon-based hard template in turn (Ludox-HS40, purchased by Sigma-Aldrich Company), 0.02g iron nitrate (III) nonahydrate, 0.005g cobalt nitrate (II) hexahydrate, stir well, add 20mL1mol / L ammonium persulfate aqueous solution, at 0 Polymerization was stirred at °C for 24 h to obtain polymer 1.

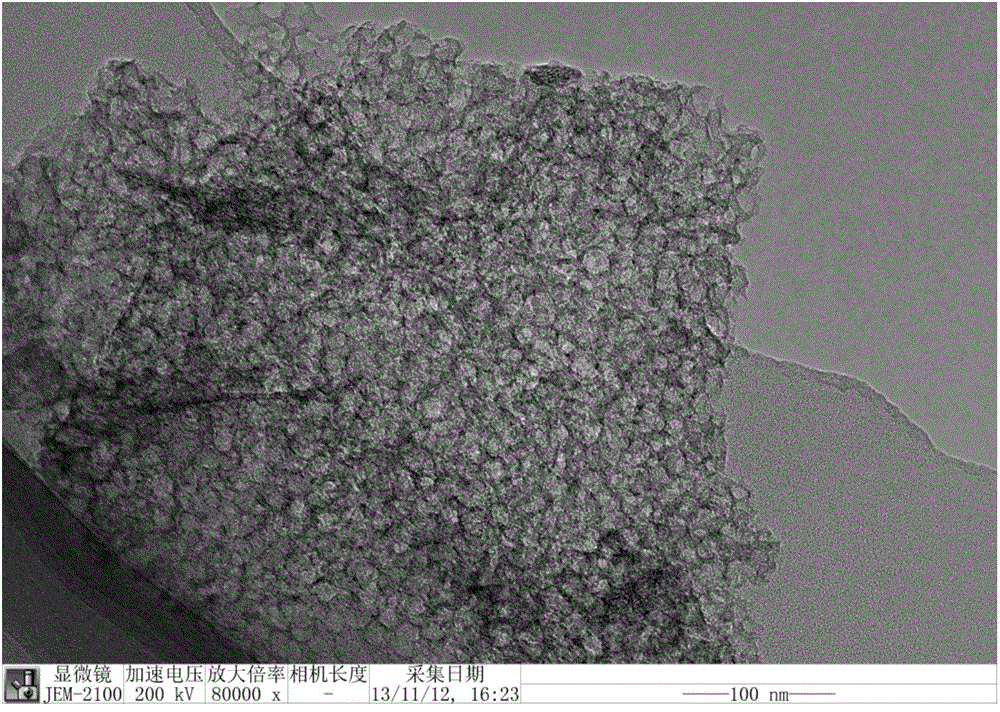

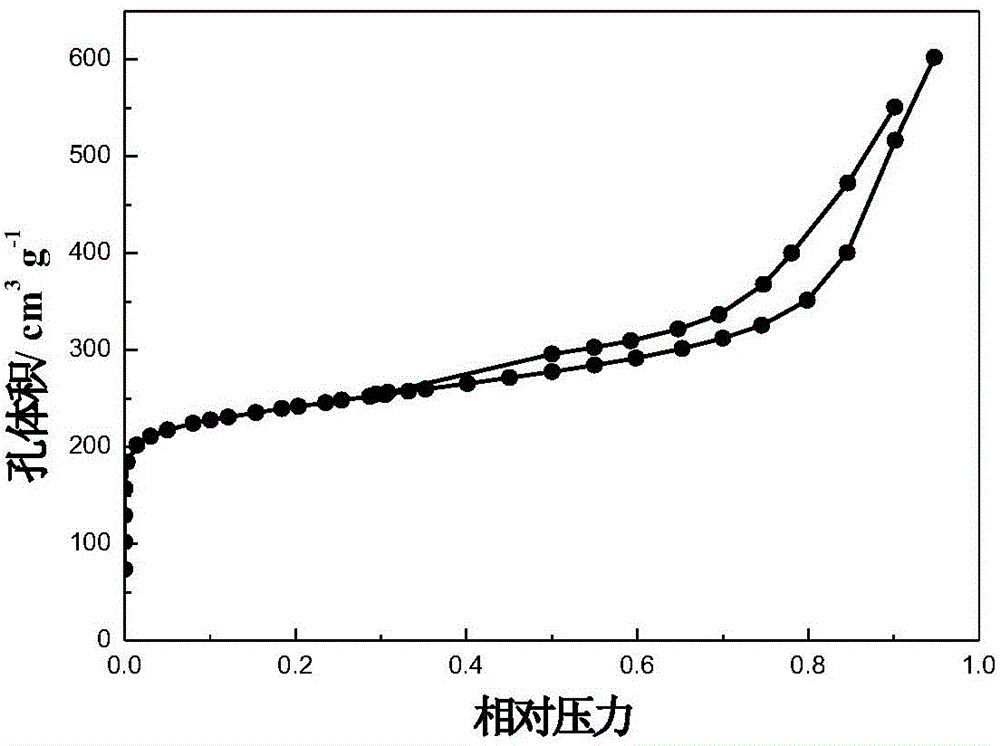

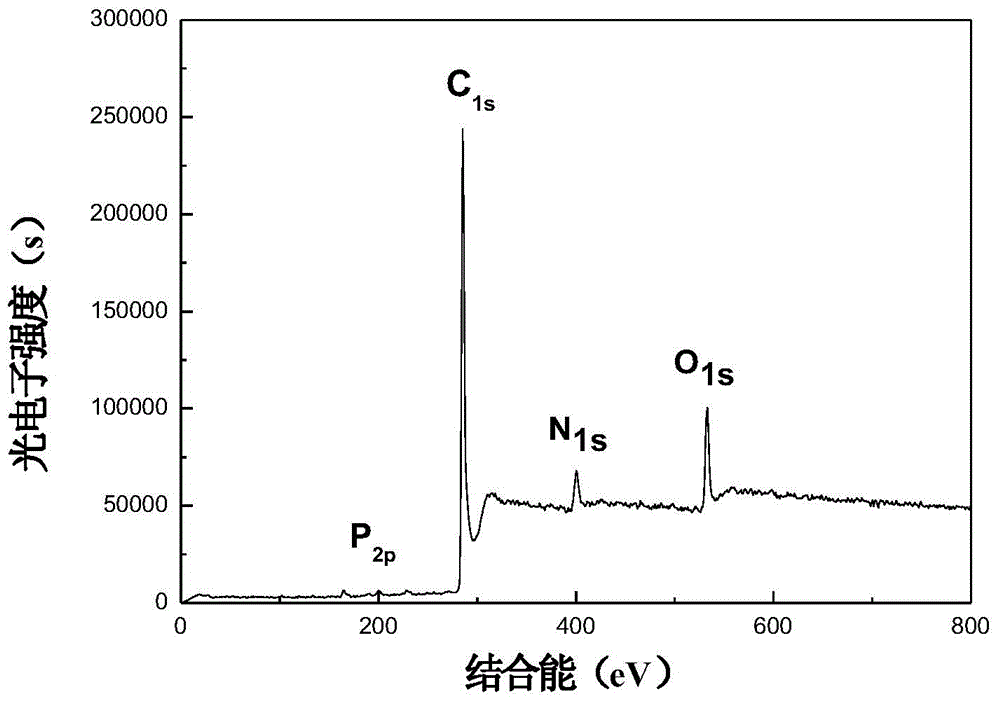

[0037] B. After polymer 1 is cooled to 25°C, it is transferred to a polytetrafluoroethylene hydrothermal reaction kettle, and reacted at 180°C for 24 hours. After the reaction, it is naturally cooled to 25°C, and the hydrothermal substance is taken out, and dried in a water bath at 80°C. The solid 1 was obtained, and the temperature of the solid 1 was raised to 600° C. at a rate of 10° C. / min under nitrogen protection, and calcined for 1 h. The temperature was lowered to 25°C and take...

Embodiment 2

[0041] A. The quality of triphenylphosphorus is changed to 0.1g, and other processing conditions are the same as in Example 1.

[0042] B. The hydrothermal reaction time is changed to 12h, and other processing conditions are the same as in Example 1.

[0043] C. Same as Example 1 to obtain a porous nitrogen-phosphorus co-doped carbon material.

[0044] The specific surface area of the porous nitrogen-phosphorus co-doped carbon material obtained by nitrogen adsorption and desorption analysis and scanning electron microscopy is 197.7m 2 g -1 , the pore size is mainly 12.7nm pores; the scanning electron microscope energy spectrum shows that the atomic percentages in the porous nitrogen-phosphorus co-doped carbon material are 85.0% carbon, 2.8% oxygen, 4.26% nitrogen, and 0.1% phosphorus.

Embodiment 3

[0046] A. The mass of triphenylphosphine was changed to 0.4g, the silicon-based hard template of silica nanospheres was changed to Ludox-TM40, which was purchased from Sigma-Aldrich, and other processing conditions were the same as in Example 1.

[0047] B. The hydrothermal reaction time was changed to 12 hours, the calcination temperature was changed to 800° C., and only the heating treatment was performed, that is, the holding time was 0 hours, and the other treatment conditions were the same as in Example 1.

[0048] C. Same as Example 1 to obtain a porous nitrogen-phosphorus co-doped carbon material.

[0049] The specific surface area of the porous nitrogen-phosphorus co-doped carbon material obtained by nitrogen adsorption and desorption analysis and scanning electron microscope detection is 142m 2 g -1 , the pore size is mainly 23nm pores; the scanning electron microscope energy spectrum shows that the atomic percentages in the porous nitrogen-phosphorus co-doped carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com