Preparation of a bioactive peptide from shiitake mushroom

A technology of bioactive peptides and shiitake mushrooms, applied in the fields of peptides, depsipeptides, food science, etc., to achieve the effect of improving metabolic rate, increasing the activation rate of ADH and ALDH, enhancing biological absorption and sobering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

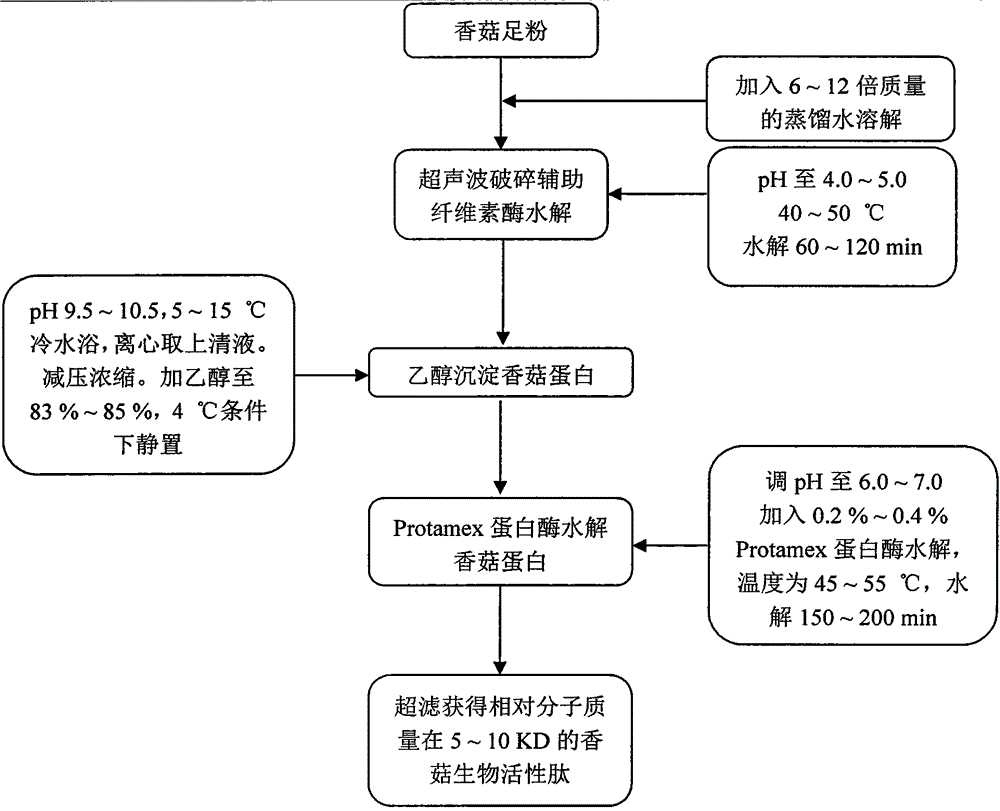

Method used

Image

Examples

Embodiment 1

[0029] Dissolution: Weigh 5.0g of shiitake mushroom powder and put it in the reactor, add 45g of distilled water to dissolve and fully stir to obtain the shiitake mushroom aqueous solution;

[0030] Wall breaking: Ultrasonic crushing for 20 minutes, adding 500 international units of cellulase, adjusting the pH to 4.5, heating to 45°C, and hydrolyzing for 60 minutes;

[0031] Precipitation: Cool to room temperature, add sodium hydroxide to adjust the pH to 10, extract in a cold water bath at 10°C for 30 minutes, centrifuge, and take the supernatant; concentrate under reduced pressure in a vacuum concentration equipment at a temperature of 44°C for 90 minutes; add Water ethanol to a concentration of 83% precipitation, ice water bath. Stand at 4°C for 60 minutes. Discard the supernatant by centrifugation, collect the precipitate, and dry at 40°C to obtain the mushroom protein:

[0032] Enzymolysis: Dissolve mushroom protein in 50 times distilled water, the unit is g. Adjust th...

Embodiment 2

[0035] Dissolving: Weigh 10.0kg of shiitake mushroom powder and place it in a reactor, add 100kg of distilled water to dissolve and fully stir to obtain an aqueous solution of shiitake mushrooms;

[0036] Wall breaking: Ultrasonic crushing for 20 minutes, adding 2 million international units of cellulase, adjusting the pH to 5.0, heating to 50°C, and hydrolyzing for 90 minutes;

[0037] Precipitation: Cool to room temperature, add sodium hydroxide to adjust the pH to about 10, extract in a cold water bath at 8°C for 40 minutes, centrifuge, and take the supernatant; concentrate under reduced pressure in a vacuum concentration equipment at a temperature of 45°C for 120 minutes; add Absolute ethanol to a concentration of 85% for precipitation, ice water bath. Stand at 4°C for 90 minutes. Discard the supernatant by centrifugation, collect the precipitate, and dry at 45°C to obtain the mushroom protein;

[0038] Enzymolysis: Dissolve the mushroom protein in 60 times distilled wat...

Embodiment 3

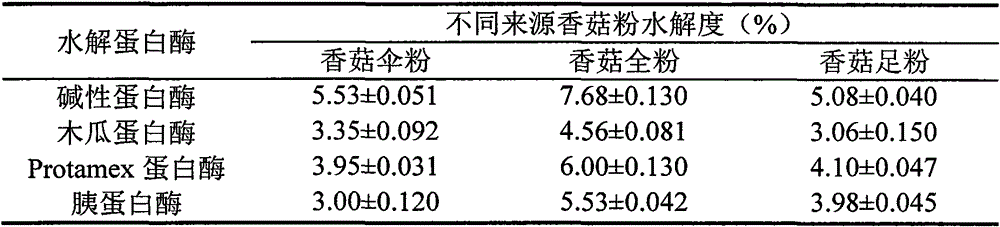

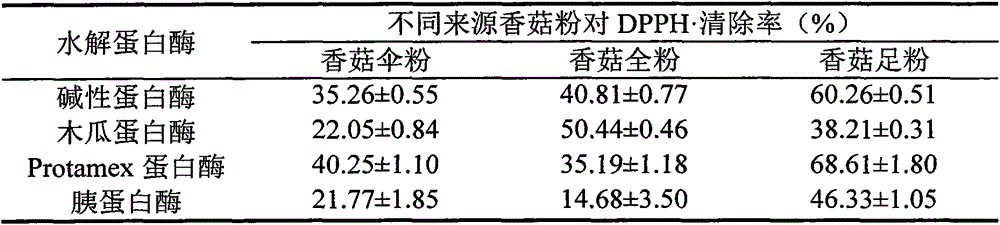

[0041] The optimal experimental conditions for papain, alkaline protease, Protamex protease, and trypsin to hydrolyze protein were obtained by consulting the literature. The above four enzymes were used to hydrolyze the same amount of shiitake mushroom powder, umbrella powder, and whole powder, and the formaldehyde titration method was used to detect The degree of hydrolysis of each hydrolyzate, the results are shown in Table 1.

[0042] Table 1 Comparison of hydrolysis degree of four kinds of enzymes to shiitake mushroom powder, whole powder and foot powder

[0043]

[0044] Note: Protamex protease was purchased from Novozymes.

[0045] As can be seen from Table 1, the present invention intends to take mushroom foot powder as the experimental raw material. As can be seen from the experimental results, taking mushroom as the substrate and the order of different enzymatic hydrolysis degrees are: alkaline protease>Protamex protease>trypsin> Papain, according to the results o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com