Method for preparing polycarbonate

A polycarbonate and polymer technology, applied in the field of preparation of new polycarbonate materials, can solve the problems of not being widely used in the chemical industry, poor dimensional thermal stability at high temperature, and low glass transition temperature, and achieve biodegradability and Improved thermal stability, improved performance such as biocompatibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

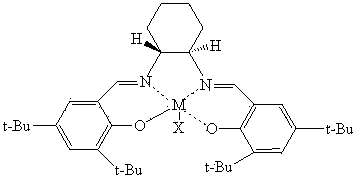

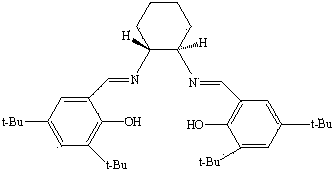

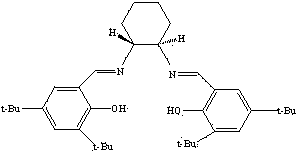

[0036] 1. The main catalyst is the tetradentate Schiff base metal complex SalenCr Ⅲ Preparation of Cl

[0037] (1) Resolution of cyclohexanediamine

[0038]Add 20g of L-(+)-tartaric acid and 60mL of distilled water into a 250mL three-necked flask equipped with a stirring bar, reflux condenser and constant pressure dropping funnel, stir until dissolved at room temperature, and the solution temperature is 60°C, then add dropwise 40mL of trans-1,2-cyclohexanediamine mixture, control the reaction temperature at 60°C, after the dropwise addition, raise the reaction temperature to a constant value and start to add glacial acetic acid dropwise, with the addition of glacial acetic acid, a white precipitate is formed, Cool to room temperature after keeping for 20min, then stir for 1h, and then cool for 1h after the end, then carry out suction filtration and washing (washing with water and ethanol three times in sequence), and dry overnight in a vacuum oven at 40°C to obtain the produc...

Embodiment 2

[0053] 1. The main catalyst is the tetradentate Schiff base metal complex SalenCr Ⅲ Preparation of Cl

[0054] (1) Resolution of cyclohexanediamine

[0055] Add 25g of L-(+)-tartaric acid and 70mL of distilled water into a 250mL three-neck flask equipped with a stirring bar, reflux condenser and constant pressure dropping funnel, stir at room temperature until dissolved, and the solution temperature is 65°C, then add dropwise 50mL of trans-1,2-cyclohexanediamine mixture, control the reaction temperature at 70°C, after the dropwise addition, raise the reaction temperature to a constant value and start adding glacial acetic acid dropwise, with the addition of glacial acetic acid, a white precipitate is formed, After keeping for 20min, cool to room temperature, stir for 2h, and cool for 2h after finishing, then carry out suction filtration and washing (washing with water and ethanol three times in sequence), and dry overnight in a vacuum oven at 50°C to obtain the product ( R, ...

Embodiment 3

[0070] 1. The main catalyst is the tetradentate Schiff base metal complex SalenCr Ⅲ Preparation of Cl

[0071] (1) Resolution of cyclohexanediamine

[0072]Add 25g of L-(+)-tartaric acid and 70mL of distilled water into a 250mL three-neck flask equipped with a stirring bar, reflux condenser and constant pressure dropping funnel, stir at room temperature until dissolved, and the solution temperature is 65°C, then add dropwise 50mL of trans-1,2-cyclohexanediamine mixture, control the reaction temperature at 70°C, after the dropwise addition, raise the reaction temperature to a constant value and start adding glacial acetic acid dropwise, with the addition of glacial acetic acid, a white precipitate is formed, After keeping for 20min, cool to room temperature, stir for 2h, and cool for 2h after finishing, then carry out suction filtration and washing (washing with water and ethanol three times in sequence), and dry overnight in a vacuum oven at 50°C to obtain the product ( R, R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com