Passivation improver for heavy metal pollution farmland and using method thereof

A technology of improver and heavy metal, applied in the direction of chemical instruments and methods, restoration and application of polluted soil, etc., can solve the problems of poor passivation effect, easy decomposition, reduced bioavailability and mobility, etc., and achieve good passivation Improve the effect of restoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the above-mentioned porous spherical cellulose, which includes:

[0042] In the first step, take 1.4kg NaOH, 2.6kg urea and 15kg water, mix them together, and stir them evenly in a mixer to obtain a dispersion medium;

[0043] In the second step, add 0.8kg of cotton pulp board to the above dispersion medium, and use a mixer to dissolve the above system for 1min, then use an ultrasonic oscillator to vibrate for 30min, and pre-cool the cellulose solution to -12°C, and put the solution at 8000r / min under the high-speed mixer to decompose for 10min to obtain the cellulose solution;

[0044] In the third step, the cellulose solution prepared in the second step is centrifuged and degassed at room temperature for 10 minutes at a rotating speed of 4000r / min to obtain a transparent cellulose solution, and 2.7% Span-80 is dissolved in liquid paraffin and stirred at a speed of 1000r / min After 30 minutes, add the above-me...

Embodiment 1

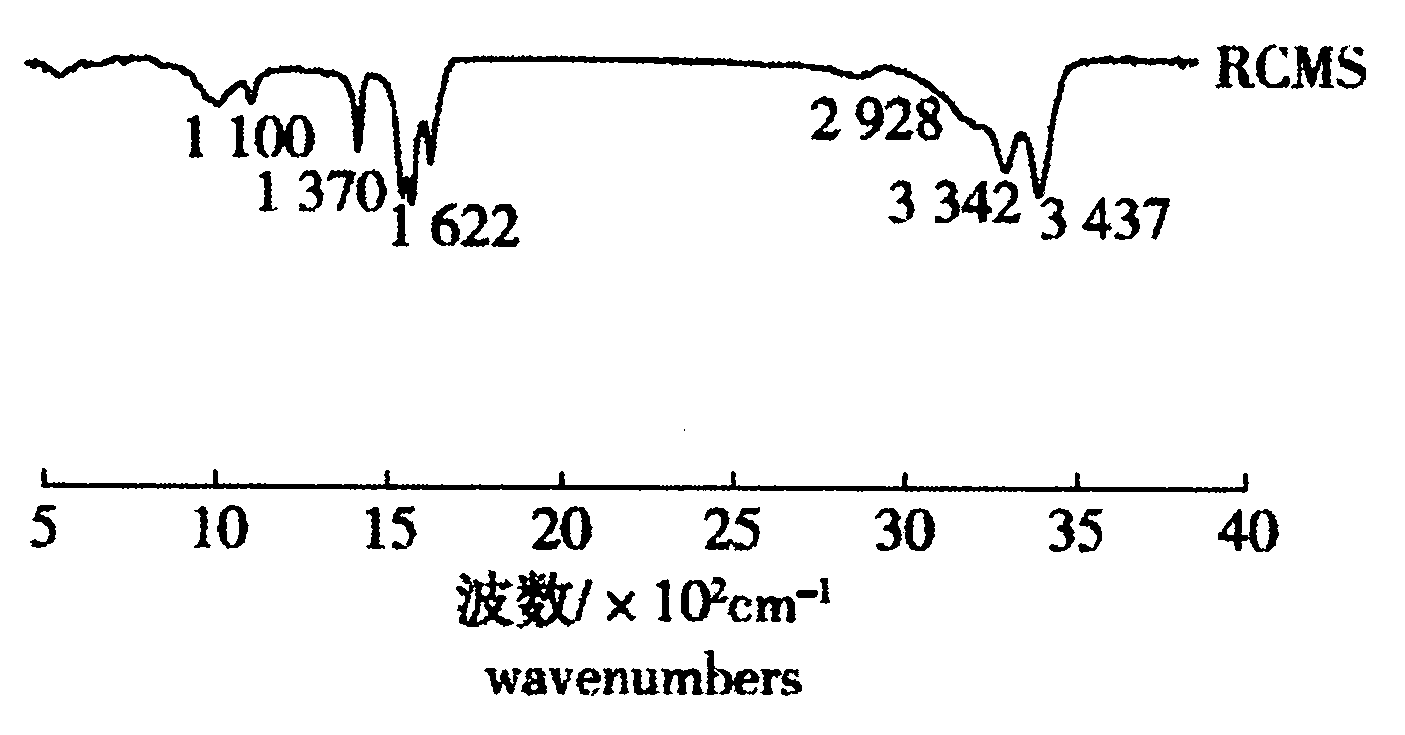

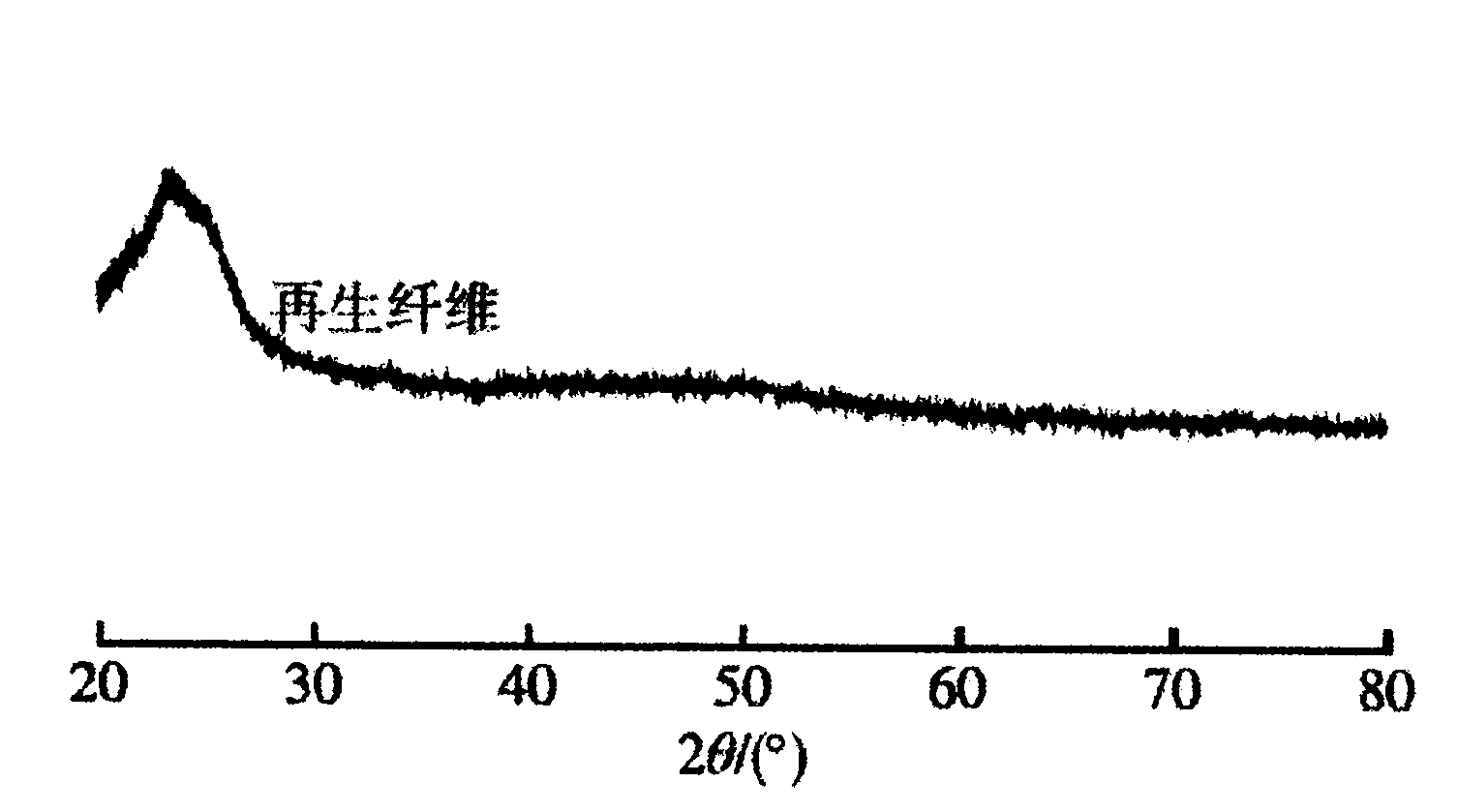

[0051] The preparation of embodiment 1 porous spherical cellulose

[0052] Take 1.4kg of NaOH, 2.6kg of urea and 15kg of water, mix them together, and stir them evenly in a mixer to obtain a dispersion medium; add 0.8kg of cotton pulp board to the above dispersion medium, and use a mixer to dissolve the above system for 1min, and then use ultrasonic vibration Shake the cellulose solution for 30 minutes, and pre-cool the cellulose solution to -12°C, decompose the solution for 10 minutes under a high-speed mixer at 8000r / min to obtain a cellulose solution; centrifuge the prepared cellulose solution at room temperature at a speed of 4000r / min After soaking for 10 minutes to obtain a transparent cellulose solution, dissolve 2.7% Span-80 in liquid paraffin and stir at a speed of 1000r / min for 30min. Stir and emulsify for 5 hours. Under the above conditions, add 10% dilute hydrochloric acid dropwise to adjust the pH to 7.0. The suspension solidifies to form regenerated cellulose mic...

Embodiment 2

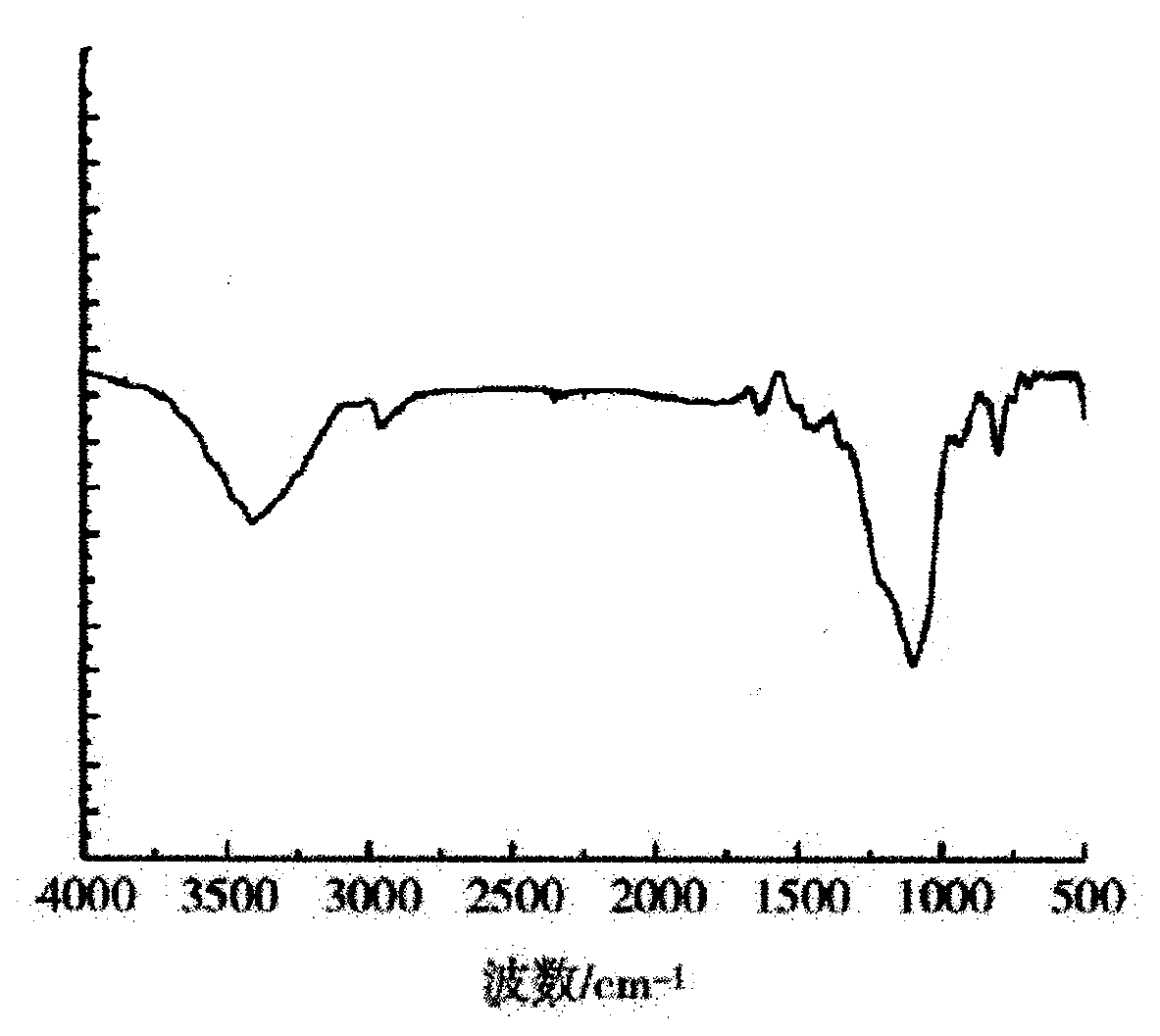

[0057] Embodiment 2 Hydroxypropyl modified SiO 2 / Preparation of Chitosan Nanoparticles

[0058] Mix 2.5L ethyl silicate, 5L absolute ethanol and 5L deionized water evenly, reflux and stir at 80°C for 1h, then adjust the pH of the solution to 6 with acetic acid, and continue stirring for 1h to make SiO 2 Sol, get 8g epichlorohydrin and acidify to pH value 6 with HCl, SiO prepared in front 2 Disperse the sol with 50L of absolute ethanol to obtain a dispersion, add the previously acidified epichlorohydrin dropwise to the dispersion, control the temperature at 40°C for 7 hours, evaporate the solvent and unreacted epichlorohydrin to obtain a white solid powder , dried in vacuum at 50°C for 6h to obtain hydroxypropylated SiO 2 , disperse 2kg chitosan in 40L isopropanol, basify with 0.3kg sodium hydroxide for 3h at a constant temperature of 40°C, then add 2.5kg hydroxypropylated SiO obtained above 2 , reacted at a constant temperature of 45°C for 5h, cooled, filtered with suctio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com