Process for preparing cadmium sulfide quantum dots by low temperature two-phase synthesis method

A synthesis method, cadmium sulfide technology, applied in cadmium sulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of increasing difficulty and difficulty in realizing industrial production, and achieve narrow size distribution, Uniform particle size and strong fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Dissolve 0.025 mmol of cadmium nitrate in 1.25 ml of oleylamine, then add 5 ml of oleic acid to dilute to prepare a cadmium solution.

[0016] (2) Add 0.0056 g (0.175 mmol) of sublimed sulfur powder and 0.0324 g (0.0875 mmol) of trioctylphosphine into 5 ml of dimethyl sulfoxide, and ultrasonically dissolve the sublimed sulfur powder at room temperature to obtain sulfur solution.

[0017] (3) Mix the cadmium solution prepared in step (1) with the sulfur solution prepared in step (2), and react in a water bath at 70 degrees for 30 minutes. After the reaction, cadmium sulfide quantum dots are formed in the oil phase. Then extract the oil phase in the reaction system, add ethanol, centrifuge, wash the obtained yellow precipitate with toluene, add ethanol, centrifuge, and finally disperse with toluene as a solvent to obtain cadmium sulfide quantum dot sol.

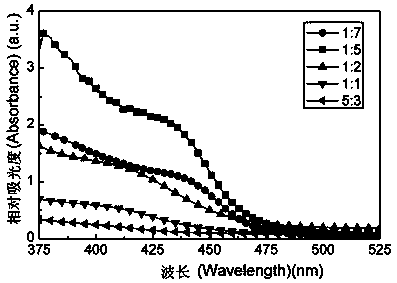

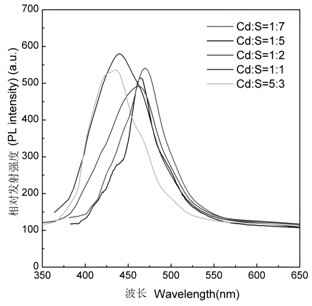

[0018] The cadmium sulfide quantum dots prepared in this embodiment are characterized, and the transmission elect...

Embodiment 2

[0020] (1) Dissolve 0.025 mmol of cadmium sulfate in 1.25 ml of oleylamine, then add 5 ml of oleic acid to dilute to prepare a cadmium solution.

[0021] (2) Add 0.004 g (0.125 mmol) of sublimed sulfur powder and 0.0232 g (0.0625 mmol) of trioctylphosphine into 5 ml of dimethyl sulfoxide, and ultrasonically dissolve the sublimed sulfur powder at room temperature to obtain sulfur solution.

[0022] (3) Mix the cadmium solution prepared in step (1) with the sulfur solution prepared in step (2), and react in a water bath at 70 degrees for 30 minutes. After the reaction, cadmium sulfide quantum dots are formed in the oil phase. Then extract the oil phase in the reaction system, add ethanol, centrifuge, wash the obtained yellow precipitate with toluene, add ethanol, centrifuge, and finally disperse with toluene as a solvent to obtain cadmium sulfide quantum dot sol.

[0023] The cadmium sulfide quantum dots prepared in this embodiment are characterized, and the transmission electr...

Embodiment 3

[0025] (1) Dissolve 0.025 mmol of cadmium chloride in 1.25 ml of oleylamine, then add 5 ml of oleic acid to dilute to prepare a cadmium solution.

[0026] (2) Add 0.0016 g (0.05 mmol) of sublimed sulfur powder and 0.0093 g (0.025 mmol) of trioctylphosphine into 5 ml of dimethyl sulfoxide, and ultrasonically dissolve the sublimed sulfur powder at room temperature to obtain sulfur solution.

[0027] (3) Mix the cadmium solution prepared in step (1) with the sulfur solution prepared in step (2), and react in a water bath at 70 degrees for 30 minutes. After the reaction, cadmium sulfide quantum dots are formed in the oil phase. Then extract the oil phase in the reaction system, add ethanol, centrifuge, wash the obtained yellow precipitate with toluene, add ethanol, centrifuge, and finally disperse with toluene as a solvent to obtain cadmium sulfide quantum dot sol.

[0028] The cadmium sulfide quantum dots prepared in this embodiment are characterized, and the transmission electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com