A kind of preparation method and product of nitrogen-doped carbon nanotube

A nanotube and nitrogen carbon technology, applied in the nano field, can solve the problems of difficulty in obtaining nitrogen-doped carbon nanotubes, difficult to put into actual industrial production, complicated preparation process, etc., achieving strong sustainability, realizing large-scale production and preparation simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of nitrogen-doped carbon nanotube in the present embodiment, carries out following operation successively:

[0042] (1) prepare the compound of melamine oxalate and cobalt oxalate

[0043] Add 50mL of water and 1.575g of oxalic acid into a 100mL round bottom flask, stir to dissolve. Add 0.5948 g of metal salt (in this example, cobalt chloride hexahydrate). The reaction was stirred for 10 min. Add 1.26 g of melamine, reflux at 92° C. for 6 h after adding, then carry out suction filtration, washing, and drying to obtain a composite of melamine oxalate and metal oxalate (cobalt oxalate in this example). In this embodiment, the molar ratio of water: oxalic acid: melamine: metal salt is 278:5:4:1 (the crystal water in the metal salt is free water, which is not included in the molar amount of water).

[0044] In this embodiment, what is obtained after reflux is a suspension, the concentration of melamine oxalate in this suspension is 0.2mol / L, and th...

Embodiment 2

[0052] The preparation method of the nitrogen-doped carbon nanotubes of this embodiment is the same as that of Example 1, except that the water added in step (1) is 100 mL, that is, the molar ratio of water: oxalic acid: melamine: metal salt is 556:5: 4:1.

[0053] What obtain after reflux among the present embodiment is suspension, the concentration of melamine oxalate in this suspension is 0.1mol / L, the mol ratio of the melamine oxalate that obtains after further suction filtration, washing, drying and cobalt oxalate is 4:1.

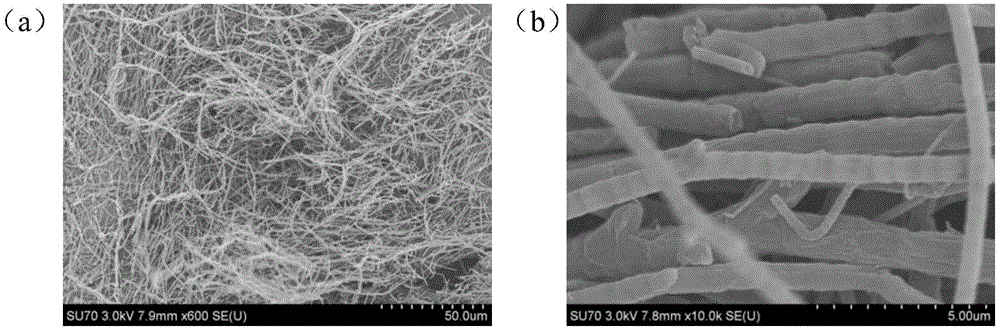

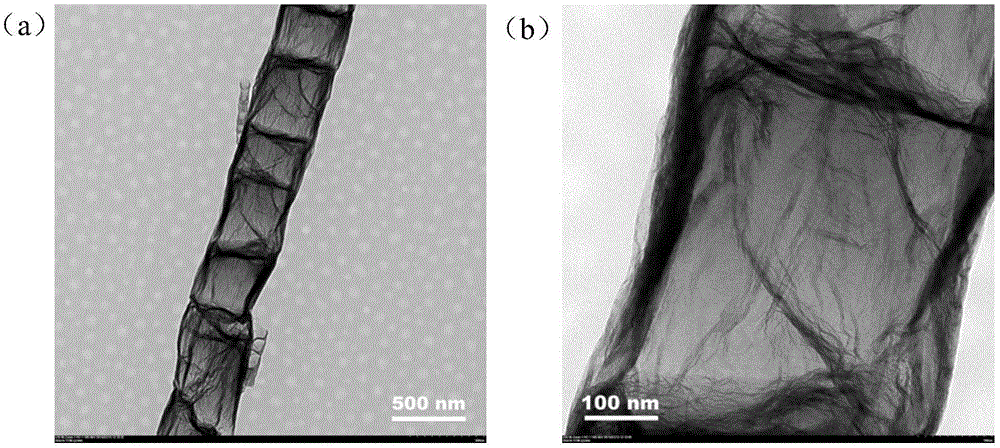

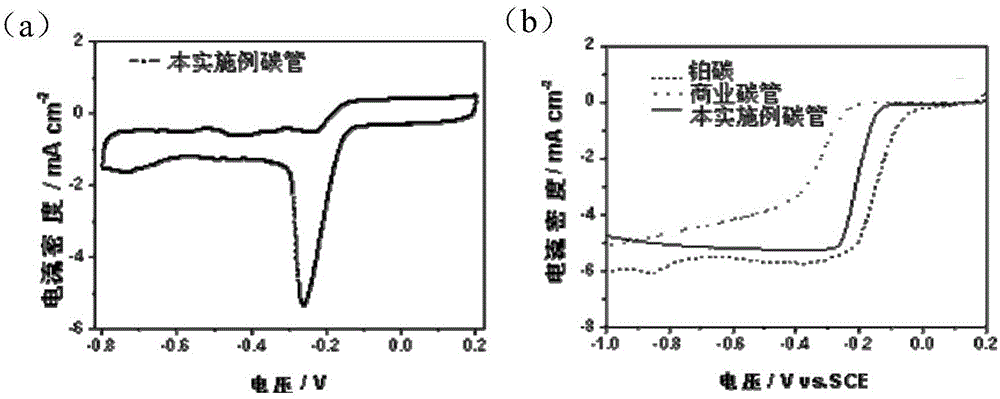

[0054] The morphology of the nitrogen-doped carbon nanotubes prepared in this example is as follows: Figure 4 shown, where Figure 4 (a) and (b) have different resolutions. It can be seen from the figure that the nitrogen-doped carbon nanotubes in this example have a length of more than 100 μm, a diameter of about 100 nm, and a bamboo-like structure without curling, and are evenly distributed within the range of 200 μm×150 μm.

Embodiment 3

[0056] The preparation method of nitrogen-doped carbon nanotubes in this embodiment is the same as that in Embodiment 1, except that the metal salt in step (1) is nickel chloride hexahydrate, and correspondingly, the obtained metal oxalate is nickel oxalate. And the quality of the added metal salt is 0.5940g, to ensure that the molar ratio of oxalic acid in this embodiment: water: metal salt: melamine is the same as that in Example 1.

[0057] What obtain after reflux among the present embodiment is suspension, the concentration of melamine oxalate in this suspension is 0.2mol / L, the mol ratio of the melamine oxalate that obtains after further suction filtration, washing, drying and nickel oxalate is 4:1.

[0058] The morphology of the nitrogen-doped carbon nanotubes prepared in this example is as follows: Figure 5 shown, where Figure 5 (a) and (b) have different resolutions. It can be seen from the figure that the nitrogen-doped carbon nanotubes in this example have a le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com