Organic fertilizer prepared from antiviral granule medicine dregs and preparation method thereof

An anti-virus and organic fertilizer technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, can solve the problems of excessive heavy metal content in terminal fertilizer products, incomplete conversion of organic fertilizer components, and large energy and labor consumption. , to achieve the effect of short drying time, stable product quality and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

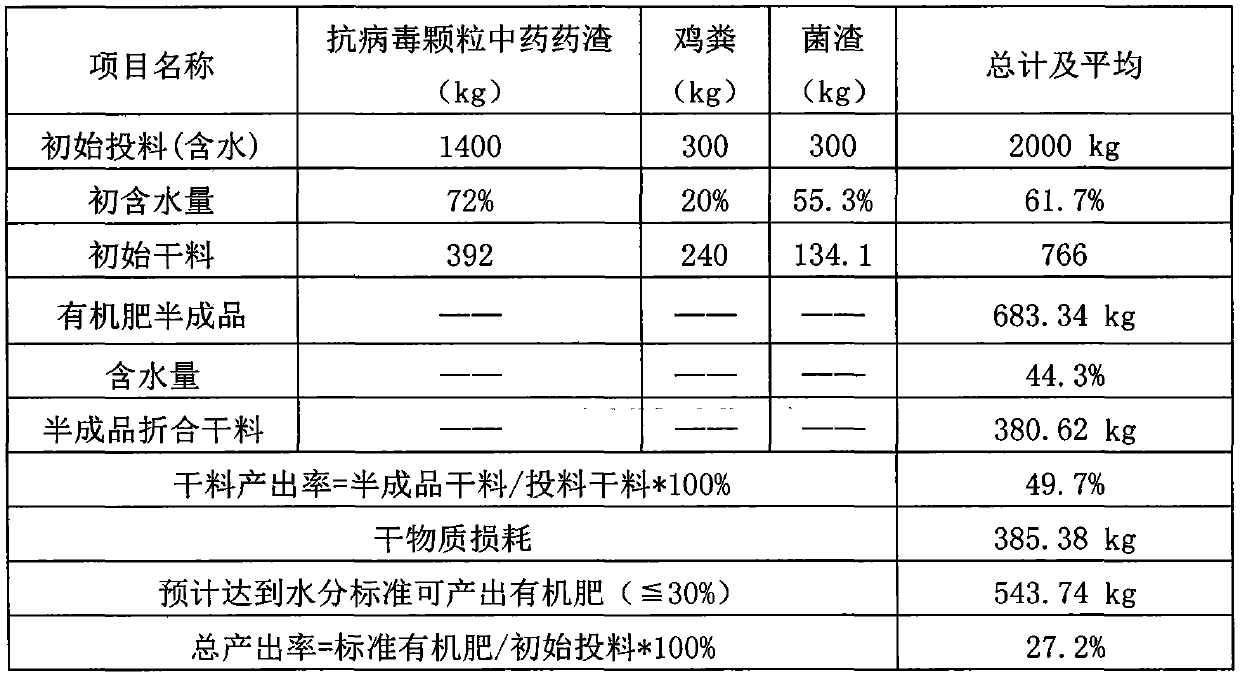

Examples

Embodiment 1

[0069] The preparation of embodiment 1 fermentation bacterial agent

[0070] (1) Preparation of Bacillus subtilis bacterial liquid: Weigh 10 grams of beef extract, 10 grams of peptone, 5 grams of sodium chloride, 5 mg of manganese sulfate, and 15 grams of agar (not added to the liquid medium) and fully dissolve them in 1000 milliliters of distilled water medium, adjust the pH to 7.0-7.2, divide into 150ml Erlenmeyer flasks, sterilize at 121°C for 20 minutes, make a plate when the temperature drops to about 50°C, insert Bacillus subtilis strains after cooling, and place Cultivate in a constant temperature incubator at 45°C for 24 hours, then transfer to a liquid medium, and cultivate in a constant temperature shaker at 45°C for 24 hours to obtain a Bacillus subtilis liquid with a viable count greater than 1×10 7 individual / ml.

[0071] (2) Preparation of Bacillus licheniformis bacterial liquid: take by weighing 5.0 grams of beef extract, 3.0 grams of peptone, 5.0 grams of yeas...

Embodiment 2

[0076] (1) directly pulverize the fresh Chinese medicine dregs after extracting the medicinal liquid to obtain coarse Chinese medicine dregs powder;

[0077] (2) Mix the pulverized coarse traditional Chinese medicine dregs powder with the chicken manure material in proportion, after fully mixing, add the self-screened fermentation agent to obtain the pre-fermentation mixture;

[0078] (3) Transfer the mixture into the fermentation tank, pile it up into stacks with a width of 1.5-2m, a height of 0.8-1.2m, and a length of more than 2m for fermentation. Aerobic fermentation, after 36 days of fermentation, the pile temperature drops below 40°C and the water content drops to 44%;

[0079] (4) Pulverize the fermented mixture and pass through a 2mm sieve and a 5mm sieve to obtain a semi-finished organic fertilizer with good commerciality. Can not return step (3) by the material of 5mm sieve;

[0080] (5) aging the semi-finished organic fertilizer for 20 days;

[0081] (6) Spread a...

Embodiment 3

[0094](1) directly pulverize the fresh Chinese medicine dregs after extracting the medicinal liquid to obtain coarse Chinese medicine dregs powder and coarse Chinese medicine dregs powder;

[0095] (2) The coarse Chinese medicine slag powder after pulverizing is mixed in proportion with chicken manure material, the mixing ratio of described thick Chinese medicine slag powder and chicken manure is 14: 3, and the water content of chicken manure is 15%, fully After mixing, the self-selected fermenting agent is added, and the fermenting agent is composed of a mixture of Bacillus subtilis, Bacillus licheniformis and Aspergillus niger. Obtaining a pre-fermentation mixture, the pre-fermentation mixture has a water content of about 60%;

[0096] (3) Transfer the mixture into a fermentation tank for fermentation, control the fermentation temperature range in the pile to 60-70°C, and turn the pile in time to promote aerobic fermentation. After 36 days of fermentation, the pile temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com