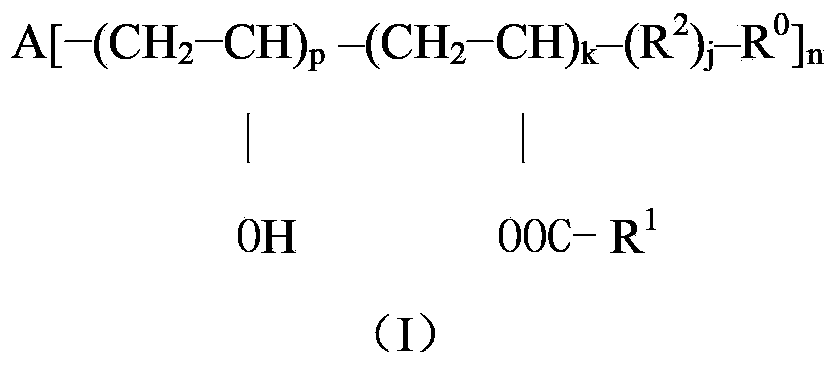

Modified vinyl alcohol-series polymer and its preparation method and use

A vinyl alcohol-based polymer technology, applied in the direction of monocarboxylic acid ester copolymer adhesives, dehydration/demulsification by chemical methods, adhesive types, etc., can solve the problems of difficult active polymerization of vinyl ester monomers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This example is the preparation of vinyl alcohol polymers modified by cationic groups by the traditional free radical copolymerization method

[0063] A. Polymerization

[0064] Into a 250ml four-necked flask equipped with a stirrer, a constant pressure dropping funnel, nitrogen ventilation and a reflux condensing device, add 100ml of methanol, 0.338mmol of methylenebismethacrylamide, 300mmol of vinyl formate, and Azodiisobutyronitrile (AIBN) 0.45mmol, n-butyl mercaptan (DDT) 0.01mmol. Place the four-necked bottle in a temperature-controlled water bath, blow nitrogen and oxygen for 30 minutes, raise the temperature to 60°C while stirring, and after stirring and reacting at 60°C for 10 minutes, continuously and slowly dropwise add 24mmol ethyleneoxyethyl The dimethylamine-containing 10% ethyleneoxyethyldimethylamine-methanol mixture was dropped within 90 minutes, and the reaction was completed after another 30 minutes.

[0065] B. Saponification

[0066] After the end...

Embodiment 2

[0071] This example is the preparation of vinyl alcohol-based polymers modified by anionic groups by the traditional free radical copolymerization method

[0072] A. Polymerization

[0073] In a 250ml four-necked flask equipped with a stirrer, constant pressure dropping funnel, nitrogen gas and reflux condensing device, add methanol 100ml, ethylene glycol diester dimethacrylate 1.2mmol, vinyl propionate 300mmol, Dibenzoyl peroxide (BPO) 0.9mmol, dodecyl mercaptan (DDT) 0.01mmol. Place the four-necked bottle in a temperature-controlled water bath, blow nitrogen and oxygen for 28 minutes, raise the temperature to 62°C while stirring, and after stirring and reacting at 62°C for 8 minutes, slowly and continuously dropwise add 9mmol of methacryloyloxygen to the system The mixture of ethylsulfonic acid and methanol containing 10% methacryloyloxyethylsulfonic acid was dropped within 120 minutes, and the reaction was completed after another 20 minutes.

[0074] B. Saponification

...

Embodiment 3

[0079] This example is the preparation of vinyl alcohol polymers modified by cationic groups by the traditional free radical copolymerization method

[0080] A. Polymerization

[0081] Into a 250ml four-necked flask equipped with a stirrer, constant pressure dropping funnel, nitrogen gas and reflux condensing device, add methanol 110ml, diisopropenylbenzene 0.27mmol, vinyl acetate 300mmol, azobisisoheptyl Nitrile (ABVN) 0.3mmol, dodecyl mercaptan (DDT) 0.006mmol. Place the four-necked bottle in a temperature-controlled water bath, blow nitrogen and oxygen for 35 minutes, raise the temperature to 58°C while stirring, and stir and react at 58°C for 16 minutes, then continuously and slowly dropwise add 105mmol methacryloyl oxygen The mixture of ethyltriethylammonium chloride and methanol containing 10% methacryloyloxyethyltriethylammonium chloride was dropped within 60 minutes, and the reaction was completed after another 5 minutes.

[0082] B. Saponification

[0083] After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com