Flexible inorganic fiber material and its preparation method

An inorganic fiber and flexible technology, applied in the field of fiber materials and its preparation, can solve the problems of low content of ceramic components, low content of inorganic components, poor fiber continuity, etc., and achieve the effect of high yield and high content of inorganic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

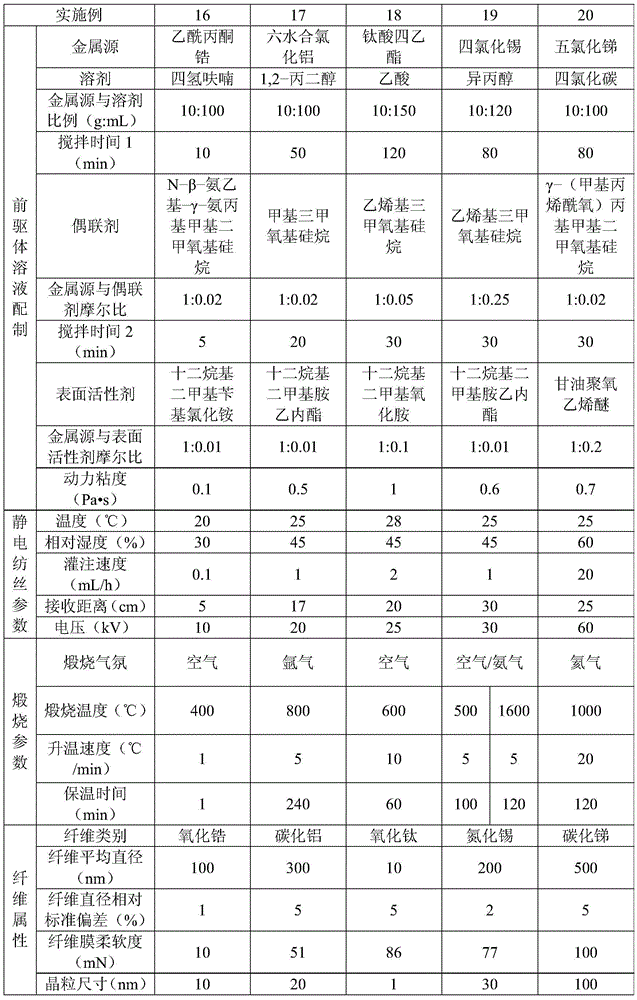

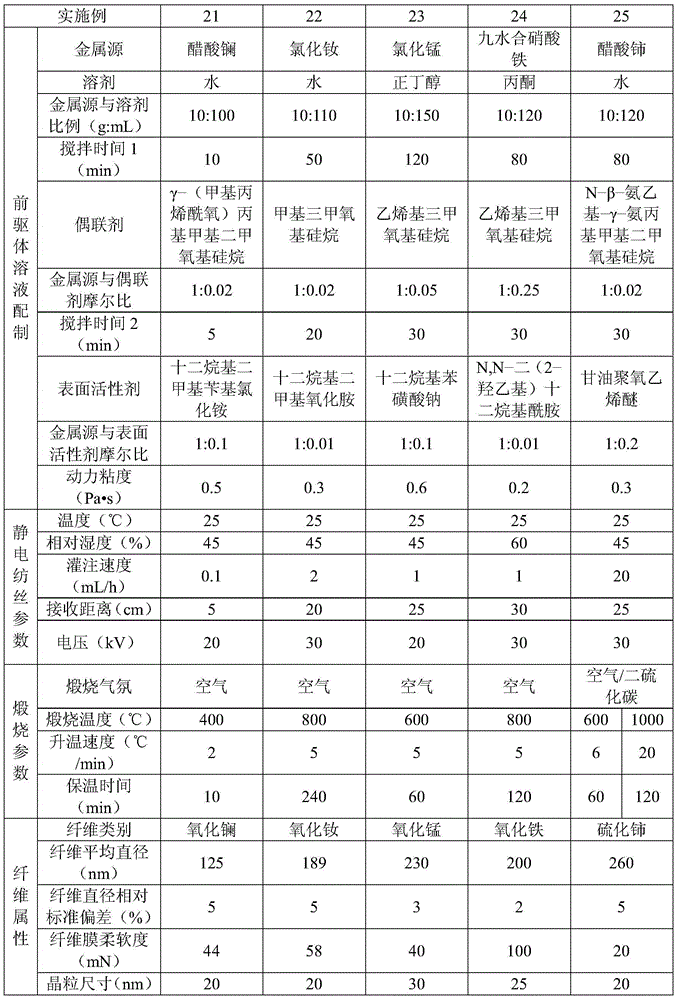

Examples

Embodiment 1

[0101] A method for preparing flexible zirconia fiber material, the specific steps are:

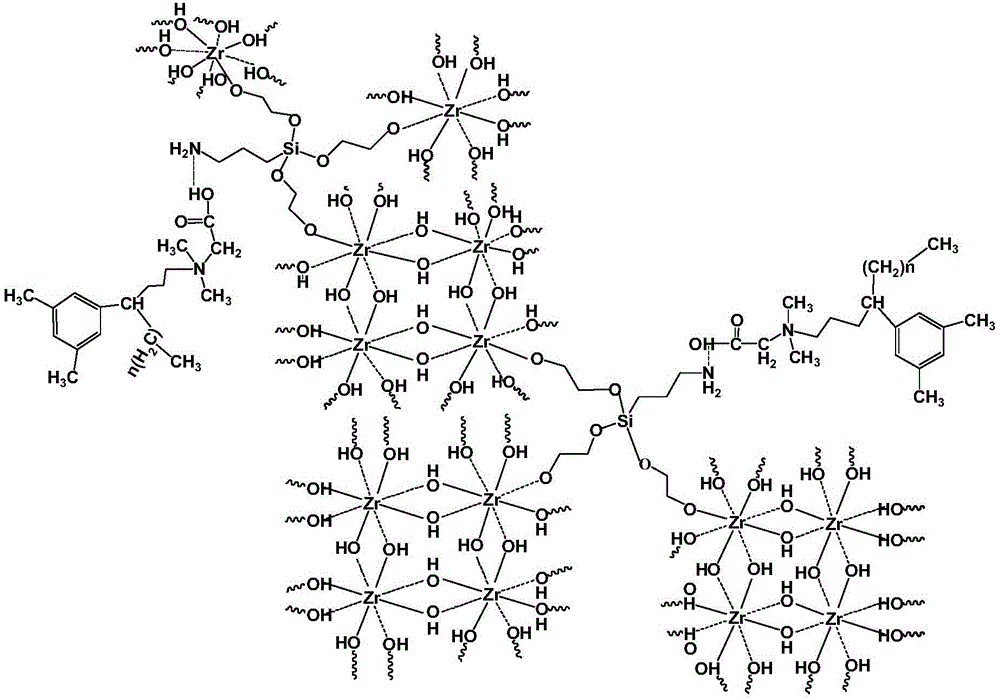

[0102] Step 1: Dissolve zirconyl nitrate in water, add coupling agent γ-aminopropyltriethoxysilane after stirring for 10 minutes, continue stirring for 5 minutes, and add surfactant dodecyldimethylbenzyl chloride Ammonium, where the ratio of zirconyl nitrate to water is 10g:50mL, the molar ratio of zirconyl nitrate to coupling agent γ-aminopropyltriethoxysilane is 1:0.02, and the ratio of zirconyl nitrate to surfactant dodecane The molar ratio of dimethylbenzylammonium chloride is 1:0.01; the uniform and stable precursor solution with a dynamic viscosity of 0.1Pa·s is prepared by mixing uniformly, and the precursor solution has an interpenetrating three-dimensional network Structure molecular chain, its structural formula is as follows:

[0103]

[0104] The second step: the above precursor solution is made into precursor fiber material through the electrospinning process; the electrospinning...

Embodiment 2

[0107] A method for preparing flexible aluminum carbide fiber material, the specific steps are:

[0108] Step 1: Dissolve aluminum isopropoxide in water / acetic acid / ethanol, add coupling agent N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane after stirring for 100 minutes, and continue stirring for 15 minutes Then add the surfactant dodecyl dimethyl amine oxide, where the ratio of aluminum isopropoxide to water / acetic acid / ethanol is 10g:70mL, the volume ratio of water / acetic acid / ethanol is 4:1:1, isopropyl The molar ratio of aluminum alkoxide to coupling agent N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane is 1:0.25, aluminum isopropoxide and surfactant dodecyl dimethyl oxidation The molar ratio of the amine is 1:0.01; the mixture is uniformly mixed to prepare a uniform and stable precursor solution with a dynamic viscosity of 2Pa·s, and the precursor solution has molecules with an interpenetrating three-dimensional network structure similar to that in Example 1. chain;

[...

Embodiment 3

[0112] A preparation method of flexible titanium carbide fiber material, the specific steps are:

[0113] The first step: Dissolve tetrabutyl titanate in acetic acid / ethanol, stir for 80 minutes and add the coupling agent vinyl trimethoxysilane, continue stirring for 30 minutes, and then add the surfactant N,N-bis(2-hydroxyethyl) Base) dodecyl amide, in which the ratio of tetrabutyl titanate to acetic acid / ethanol is 10g:150mL, the volume ratio of acetic acid to ethanol is 3:1, tetrabutyl titanate and the coupling agent vinyl trimethoxy The molar ratio of silane is 1:0.08, and the molar ratio of tetrabutyl titanate to surfactant N,N-bis(2-hydroxyethyl)dodecyl amide is 1:0.05; mix evenly to make uniform and stable A precursor solution with a dynamic viscosity of 0.1 Pa·s, the precursor solution having an interpenetrating three-dimensional network structure molecular chain similar to that of Example 1;

[0114] The second step: the above precursor solution is made into precursor fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com