Li-S battery and Li-S reserve battery capable of performing impulsive discharge, and preparation methods thereof

A reserve battery and pulse discharge technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve problems that affect battery energy efficiency and service life, reduce current density, and hinder cation migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

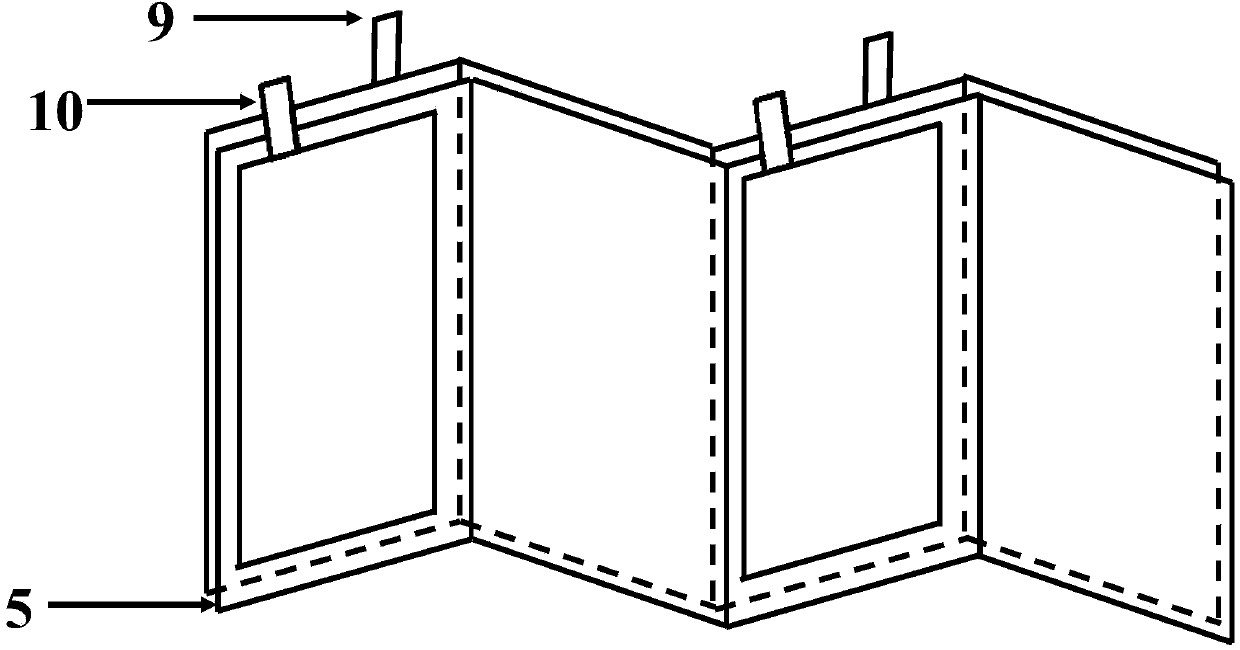

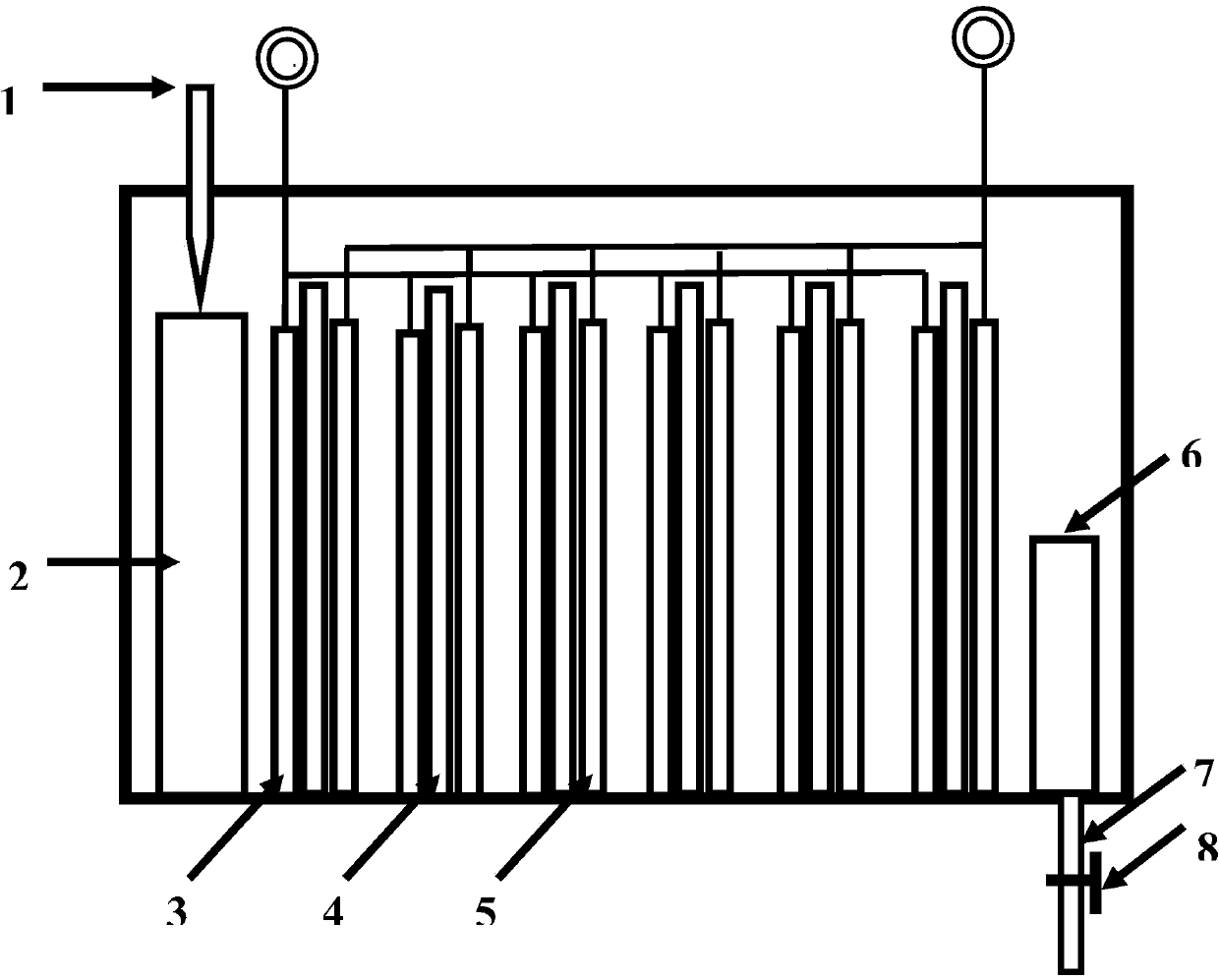

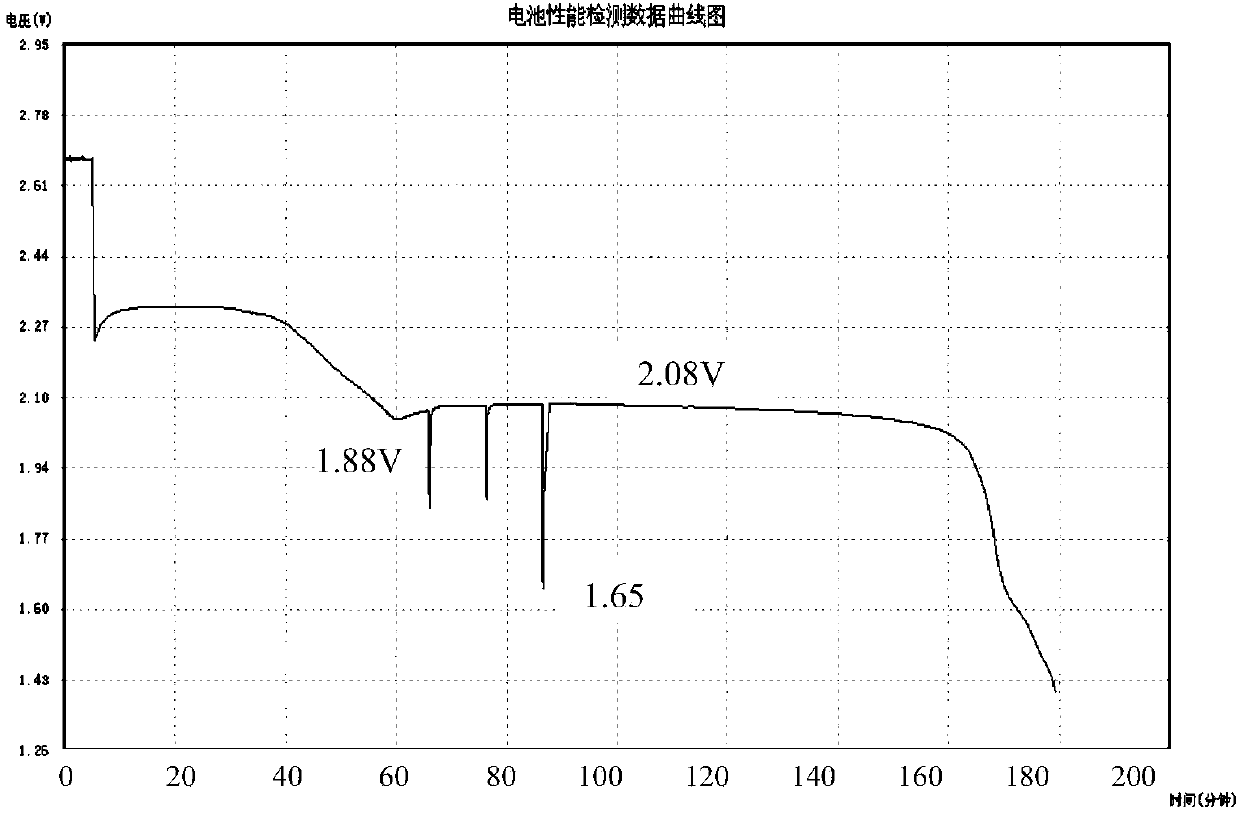

[0040] a kind of like figure 2 The pulse-dischargeable Li-S storage battery shown can be a single battery, a battery stack or an electrode group, etc., and the storage battery includes a bubble-type liquid storage structure 2 for storing electrolyte for a long time and is composed of A battery cell composed of a positive electrode assembly 3, a negative electrode assembly 4, and a separator 5. The battery cell is made by winding or laminating. The positive electrode assembly 3 includes an aluminum current collector and a positive electrode active material and adhesive coated on the aluminum current collector. mixture (sulfur-containing cathode slurry coating), the anode active material is a carbon-sulfur compound, and the binder is polyvinylidene fluoride; the anode assembly 4 is mainly a lithium metal sheet, and the diaphragm 5 is a composite diaphragm with barrier properties to anions , the composite diaphragm is mainly composed of a base film (this embodiment is a Celgard ...

Embodiment 2

[0050] a kind of like figure 2 The pulse-dischargeable Li-S storage battery shown can be a single battery, a battery stack or an electrode group, etc., and the storage battery includes a bubble-type liquid storage structure 2 for storing electrolyte for a long time and is composed of A battery cell composed of a positive electrode assembly 3, a negative electrode assembly 4, and a separator 5. The battery cell is made by winding or laminating. The positive electrode assembly 3 includes an aluminum current collector and a positive electrode active material and adhesive coated on the aluminum current collector. mixture (sulfur-containing cathode slurry coating), the anode active material is a carbon-sulfur compound, and the binder is polyvinylidene fluoride; the anode assembly 4 is mainly a lithium metal sheet, and the diaphragm 5 is a composite diaphragm with barrier properties to anions , the composite diaphragm is mainly composed of a base film (this embodiment is a Celgard ...

Embodiment 3

[0060]The lithium perfluorosulfonamide polymer electrolyte in the above embodiments can also be a lithium perfluorosulfonyl carboxylate polymer electrolyte, and other process parameters, process conditions and raw materials are the same as those in Example 1 or Example 2.

[0061] The preparation method of perfluorosulfonyl carboxylate lithium polymer electrolyte in this embodiment specifically includes the following steps:

[0062] (1) Dissolve 0.6g of carbamoyl chloride in 200g of anisole, then add 25g of perfluorosulfonyl fluoride resin to the solution, stir and reflux at 70°C for 15h under a nitrogen atmosphere, remove unreacted raw materials and By-products are precipitated to obtain perfluorosulfonylformyl chloride resin polymers containing sulfonylformyl chloride groups in their side chains. The perfluorosulfonylformyl chloride resin polymer was filtered and washed with a mixed solvent such as ethanol and water, and then dried to obtain 26.8 g of a solid product. The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com