Antimicrobial fabric for medical partition curtain

A technology of antibacterial fabrics and curtains, applied in the field of medical fabrics, can solve the problems of low surface load rate, discounted antibacterial effect, poor adhesion between carrier and antibacterial nanomaterials, etc., to achieve the effect of inhibiting the reproduction of bacteria and excellent waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation of embodiment 1 modifying agent

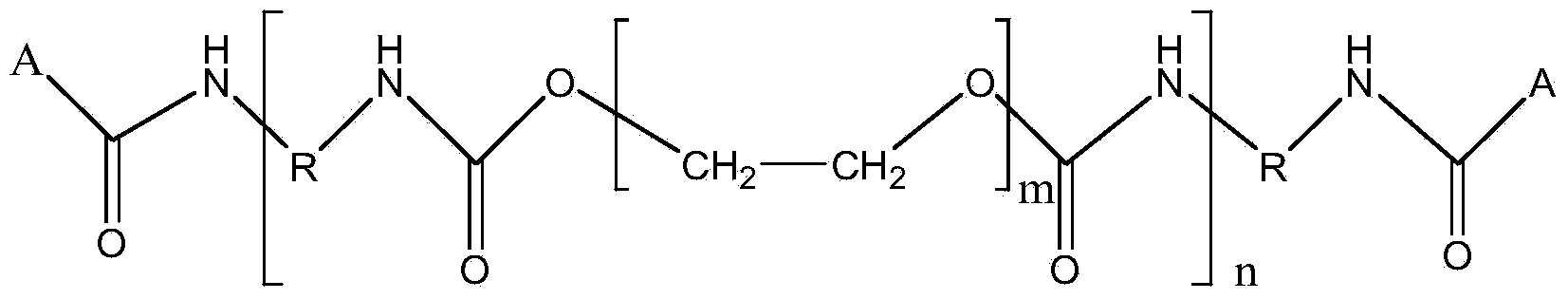

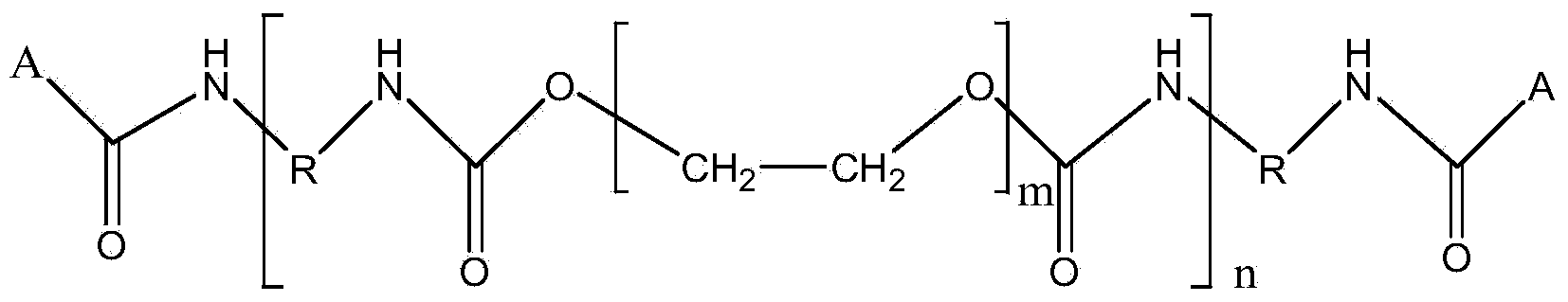

[0017] Modifier used in the present invention is the compound with following general structure:

[0018]

[0019] In the above general structure, A is the residue after the reaction of 4-hydroxyethylimidazole and isocyanate group; R is the part of diphenylmethane-4,4,-diisocyanate except the isocyanate group. Wherein, m and n are integers, and 5≤m≤10, 3≤n≤5. The modifier consists of diphenylmethane-4,4,-diisocyanate and polyether polyols with different degrees of polymerization in toluene, acetone and other organic solvents in a certain proportion to form polyurethane with isocyanate groups at both ends of the molecular chain. Then add 4-hydroxyethylimidazole to block it and prepare it. During the reaction, in order to increase the reaction speed, the catalyst dibutyltin dilaurate can be used to control the degree of polymerization of the polyether polyol used to control the general formula The m value in the struct...

Embodiment 2

[0020] Embodiment 2 antibacterial additive A

[0021] The antibacterial additive described in the present embodiment is prepared by the following method:

[0022] (1) adding calcium carbonate particles with an average particle diameter of 10 μm into water to form a suspension with a concentration of 10wt%, then adding nanometer titanium dioxide particles and 1-vinylimidazole, controlling the temperature of the system to be 20 to 30°C, and Stirring and reacting for 30 minutes at a stirring speed of 2000rpm; wherein the average particle diameter of the nano-titanium dioxide is 20nm, the quality of the nano-titanium dioxide is 10wt% of the calcium carbonate quality, and the quality of 1-vinylimidazole is 3.0wt% of the calcium carbonate quality;

[0023] (2) Add silver nitrate, citric acid, glucose and N-vinylcaprolactam, and react at a stirring speed of 2000rpm for 20 minutes; then age for 12 hours, filter, dry and disperse to obtain nano-coated calcium carbonate particles Where...

Embodiment 3

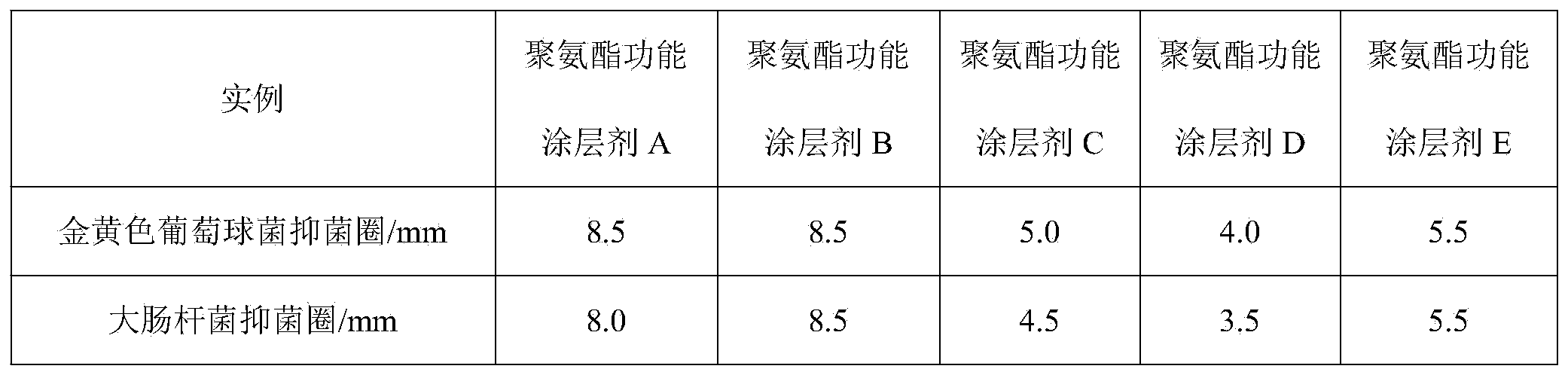

[0035] The preparation of embodiment 3 polyurethane functional coating agent A

[0036] Under the protection of dry nitrogen, polyoxypropylene diamine D-2000 after vacuum dehydration, bisphenol A polyoxyethylene ether BPE-06, carbodiimide modified 4,4,-MDI, N-methyl di Ethanolamine, 1,4-butanediol, antibacterial additive A, diethylaminoethyl methacrylate, tetraisobutyl titanate, ultraviolet absorber, antioxidant, 8-hydroxyquinolinone and an appropriate amount of solvent ( Add raw materials such as toluene and ethyl acetate) into the reactor at one time, react at 75-80°C for 2.0 hours, lower the system temperature to 20-30°C, and then add deionized water, sodium carboxymethylcellulose, polyethylene Pyrrolidone and fatty alcohol polyoxyethylene ether are dispersed for 15 to 20 minutes under the stirring condition of 3000 rpm, and then the solvent and low boilers are removed under reduced pressure to obtain the polyurethane functional coating agent. In this example, carbodiimide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com