Method for preparing porous carbon for supercapacitor with salicylate complex

A technology of supercapacitor and salicylate, which is applied in the fields of hybrid capacitor electrode, hybrid/electric double layer capacitor manufacturing, carbon preparation/purification, etc., which can solve the problem that it is difficult to obtain wide application, and metal oxides are expensive and difficult to obtain Widely used and other issues to achieve the effects of improved stability, large total pore volume, and excellent capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

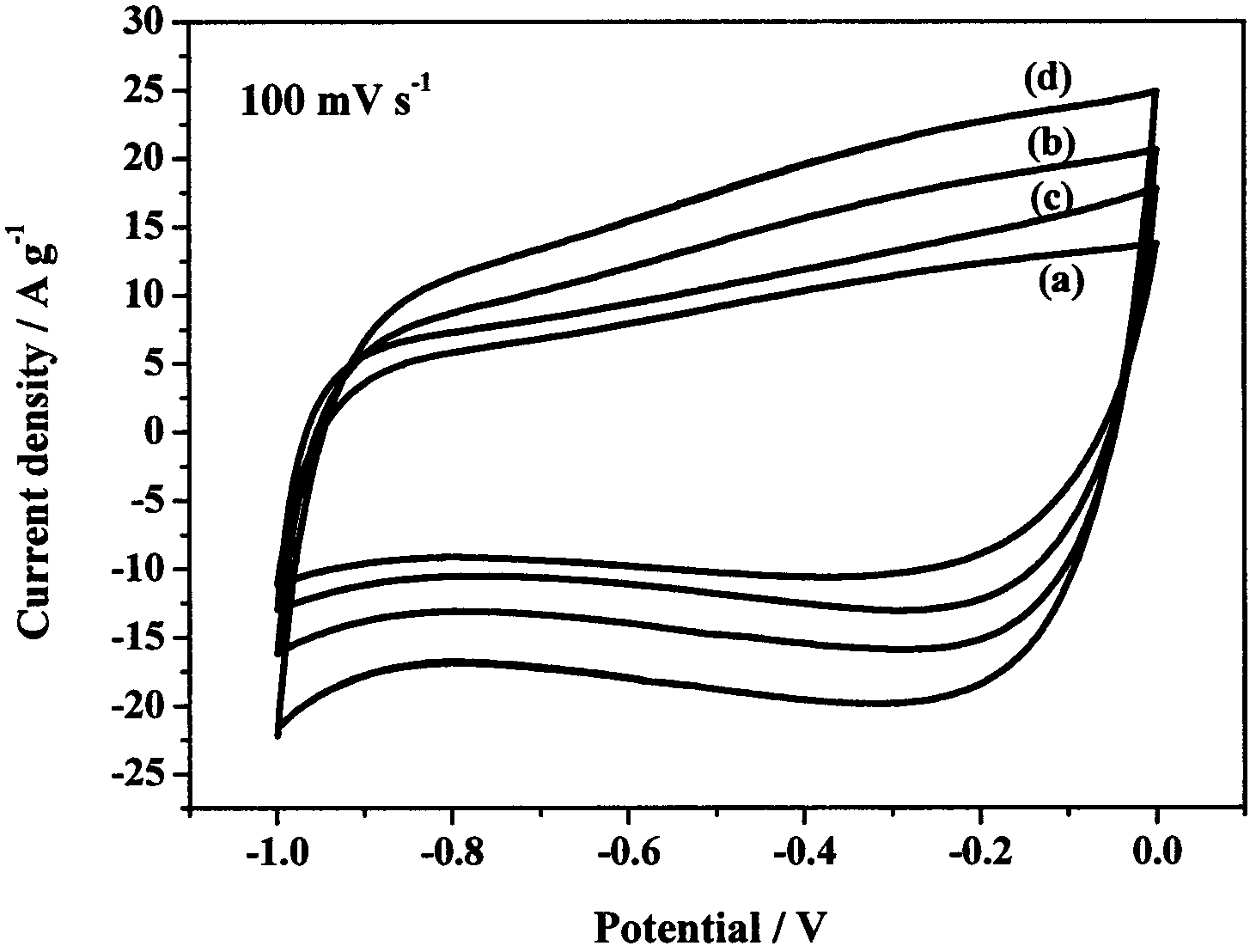

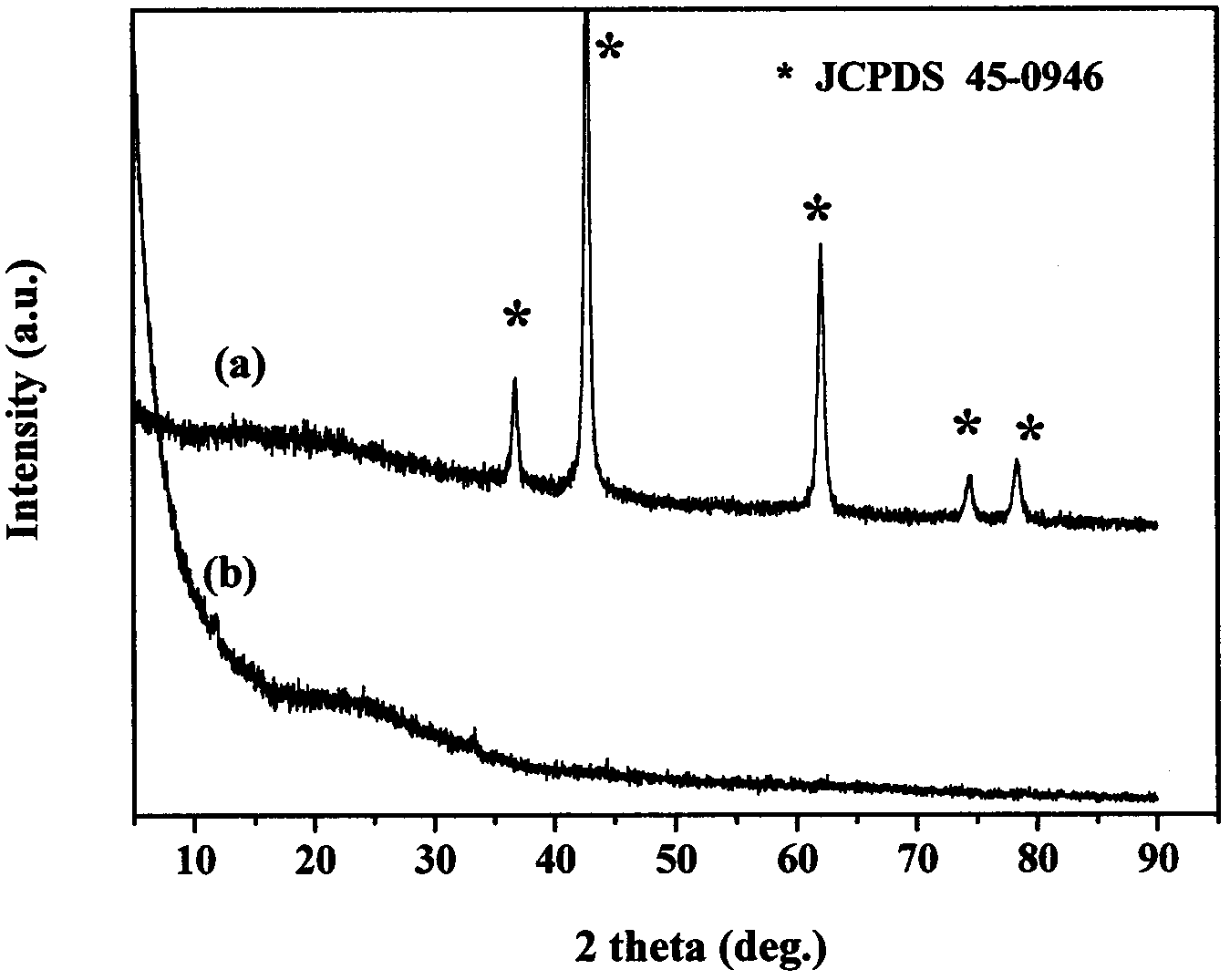

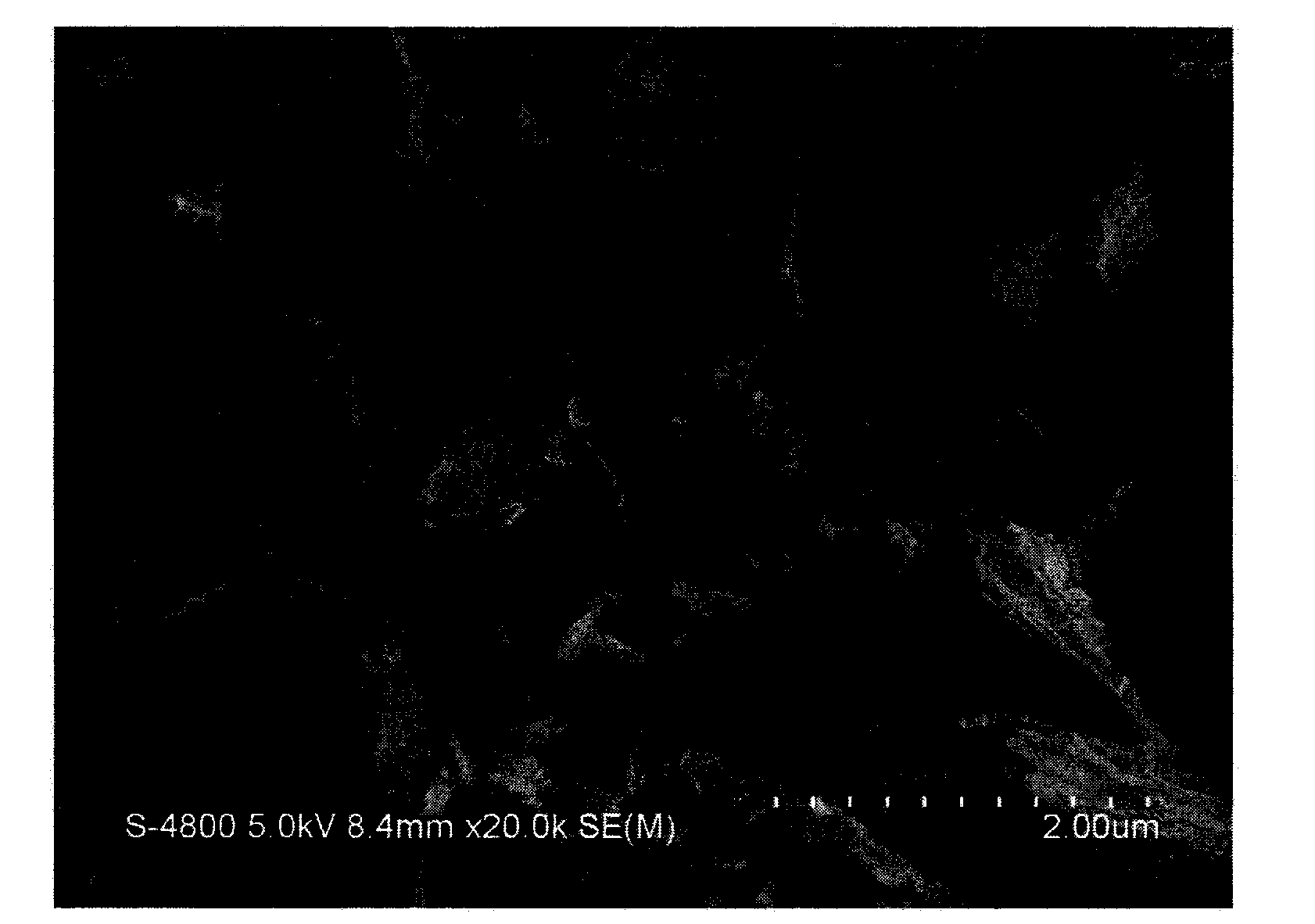

[0027] In this experiment, sodium salicylate and zinc nitrate were used to form complexes and calcined at different temperatures to prepare different porous carbon materials:

[0028] (1) Using zinc salicylate as raw material to calcinate at 800°C to prepare porous carbon

[0029] Take 3.2g of sodium salicylate and dissolve it in a beaker, and dissolve 2.97g of zinc nitrate in another beaker. Slowly pour the sodium salicylate solution into the zinc nitrate solution under stirring to form the complex zinc salicylate. After 0.5h, , filtered and washed with water until neutral, and dried in an oven at 60°C for 6 hours. Take an appropriate amount of zinc salicylate in a tube furnace in an argon atmosphere at 4°C min -1 The heating rate was raised to 800°C, and the temperature was kept constant for 2 hours. After cooling down to room temperature, the obtained sample was ultrasonically cleaned with 30% dilute hydrochloric acid or dilute nitric acid for 1 hour, stirred and reacted f...

Embodiment 2

[0034] Take 3.2g of sodium salicylate and dissolve it in a beaker, and dissolve 2.97g of zinc nitrate in another beaker. Slowly pour the sodium salicylate solution into the zinc nitrate solution under stirring to form the complex zinc salicylate. After 0.5h, , filtered and washed with water until neutral, and dried in an oven at 60°C for 6 hours. Take an appropriate amount of zinc salicylate in a tube furnace in an argon atmosphere at 4°C min -1The heating rate was increased to 900°C, and the temperature was kept constant for 2 hours. After cooling down to room temperature, the obtained sample was ultrasonically cleaned with 30% dilute hydrochloric acid or dilute nitric acid for 1 hour, stirred and reacted for 6 hours, filtered, washed with water until neutral, and dried to obtain the finished product.

[0035] In the same manner as in Example 1, the porous carbon material prepared in this example was made into a porous carbon electrode for electrochemical testing. The curve ...

Embodiment 3

[0038] Take 3.2g of sodium salicylate and dissolve it in a beaker, and dissolve 2.97g of zinc nitrate in another beaker. Slowly pour the sodium salicylate solution into the zinc nitrate solution under stirring to form the complex zinc salicylate. After 0.5h, , filtered and washed with water until neutral, and dried in an oven at 60°C for 6 hours. Take an appropriate amount of zinc salicylate in a tube furnace in an argon atmosphere at 4°C min -1 The heating rate was increased to 1000°C, and the temperature was kept constant for 2 hours. After cooling down to room temperature, the obtained sample was ultrasonically cleaned with 30% dilute hydrochloric acid or dilute nitric acid for 1 hour, stirred and reacted for 6 hours, filtered, washed with water until neutral, and dried to obtain the finished product.

[0039] In the same manner as in Example 1, the porous carbon material prepared in this example was made into a porous carbon electrode for electrochemical testing. The curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com