Carbon fiber-based coated sand material for selective laser sintering and preparation method thereof

A laser sintering and carbon fiber technology, applied in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of short laser beam irradiation time, large sand mold gas generation, poor air permeability and collapsibility, etc., to achieve rapid response manufacturing capabilities Huge, enhanced effect, improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

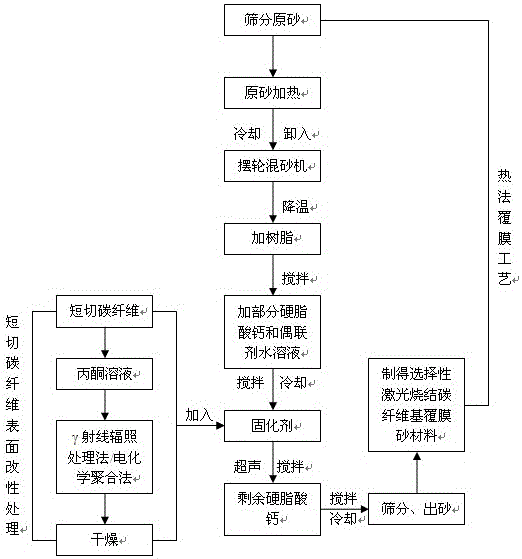

[0030] A carbon fiber-based coated sand material for selective laser sintering is carried out in the following steps:

[0031] Step 1: Use γ-ray irradiation to modify the surface of chopped carbon fibers. First, put the chopped carbon fibers with a diameter of 7 μm and a length of 2.5 mm into an acetone solution, wash them for 48 hours, and then dry them. In the irradiated bottle of tetraethylene glycol acetone solution with active functional group concentration of 2 mol / L, one end of the two vent holes of the irradiated bottle was continuously ventilated with nitrogen for 2 min, and sealed after the oxygen in the bottle was removed. Put it in a Coγ-ray irradiation source, and carry out co-irradiation grafting modification according to the irradiation dose of 200kGy. After the chopped carbon fibers were irradiated, they were cleaned with acetone and dried in a vacuum oven at 50 °C for 12 h for later use.

[0032] Step 2: Using the thermal coating process, sieve the spherical ...

Embodiment 2

[0037] A carbon fiber-based coated sand material for selective laser sintering is carried out in the following steps:

[0038] Step 1: Use electrochemical polymerization to modify the surface of chopped carbon fibers. First, put the chopped carbon fibers with a diameter of 7 μm and a length of 1.5 mm into an acetone solution for 48 hours, and then use sulfuric acid as an electrolyte to deionize Water was used as a solvent, and monomers with a mass fraction of 1% were added to form an electrolyte. Then carbon fiber was used as an anode and graphite was used as a cathode. At room temperature, electrolytic polymerization was carried out at a polymerization current of 90 mA for 60 seconds, and then deionized water was used to The surface of the chopped carbon fiber was cleaned to remove residual electrolyte ions and unpolymerized monomers on the surface, and finally it was dried in a vacuum oven at 50 °C for 12 h for later use.

[0039] Step 2: Using the thermal coating process, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com