Polyurethane (PU)/small intestine submucosa (SIS) membrane composite material and application thereof

A technology of small intestinal submucosa and composite materials, applied in medical science, prostheses, etc., can solve the problems of application limitations and single performance, and achieve good histocompatibility, excellent mechanical properties, tensile strength and elongation at break The effect of high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1 Preparation of PU / SIS composite material of the present invention

[0086] 1. Preparation of anionic water-based polyurethane emulsion

[0087] 1) Prepolymerization: Add isophorone diisocyanate (IPDI) and polytetrahydrofuran 1000 (PTMG 1000) with a molar ratio of 1.45:0.5, in which isophorone diisocyanate is 0.1mol, into a three-necked flask, and add 0.2 ml stannous octoate catalyst, pre-polymerized at 74°C for 2h50min;

[0088] 2) Chain extension: 2,2-dimethylolbutyric acid (DMBA) with a PTMG 1000 / DMBA molar ratio of 5:5 was reacted at 54° C. for 3 h. Observe the viscosity of the system during the reaction process. If necessary, add an appropriate amount of acetone to adjust the viscosity of the reaction system. Visually observe the viscosity of the reaction system that does not accumulate on the stirring rod during the stirring process, so that the reaction can be maintained in a stable state;

[0089] 3) Neutralization and emulsification: at room tempe...

Embodiment 2

[0110] Embodiment 2 Preparation of PU / SIS composite material of the present invention

[0111] 1. Preparation of anionic water-based polyurethane emulsion

[0112] 1) Prepolymerization: Add isophorone diisocyanate (IPDI) and polytetrahydrofuran 1000 (PTMG 1000) with a molar ratio of 1.45:0.5, in which isophorone diisocyanate is 0.1mol, into a three-necked flask, and add 0.2 ml stannous octoate catalyst, pre-polymerized at 74°C for 2h50min;

[0113] 2) Chain extension: 2,2-dimethylolpropionic acid (DMPA) with a molar ratio of PTMG 1000 / DMBA of 5:5 was reacted at 54° C. for 3 h. Observe the viscosity of the system during the reaction process. If necessary, add an appropriate amount of acetone to adjust the viscosity of the reaction system. Visually observe the viscosity of the reaction system that does not accumulate on the stirring rod during the stirring process, so that the reaction can be maintained in a stable state;

[0114] 3) Neutralization and emulsification: at room ...

Embodiment 3

[0126] Embodiment 3 Preparation of PU / SIS composite material of the present invention

[0127] 1. Preparation of anionic water-based polyurethane emulsion

[0128] Same as Example 2.

[0129] 2. Preparation of SIS powder

[0130] Same as Example 1.

[0131] 3. Preparation and molding of PU / SIS composite materials

[0132] 1) Preparation: 0.3 g of SIS powder was added to 10 g of polyurethane emulsion with a solid content of 21%, and stirred at room temperature for 3 hours to obtain a polyurethane / SIS sol.

[0133] 2) Forming: Pour the sol into a 24-well plate, pre-freeze at -40°C, and vacuum freeze-dry to form.

[0134] 3) Cross-linking: Soak the obtained material in 2.5% (w / v) 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride at pH 5.5 for twice the volume of the material (EDC), after cross-linking at room temperature for 36 h, washed with saturated brine three times to remove residual EDC. Wash the material with a large amount of deionized water, freeze-dry, a...

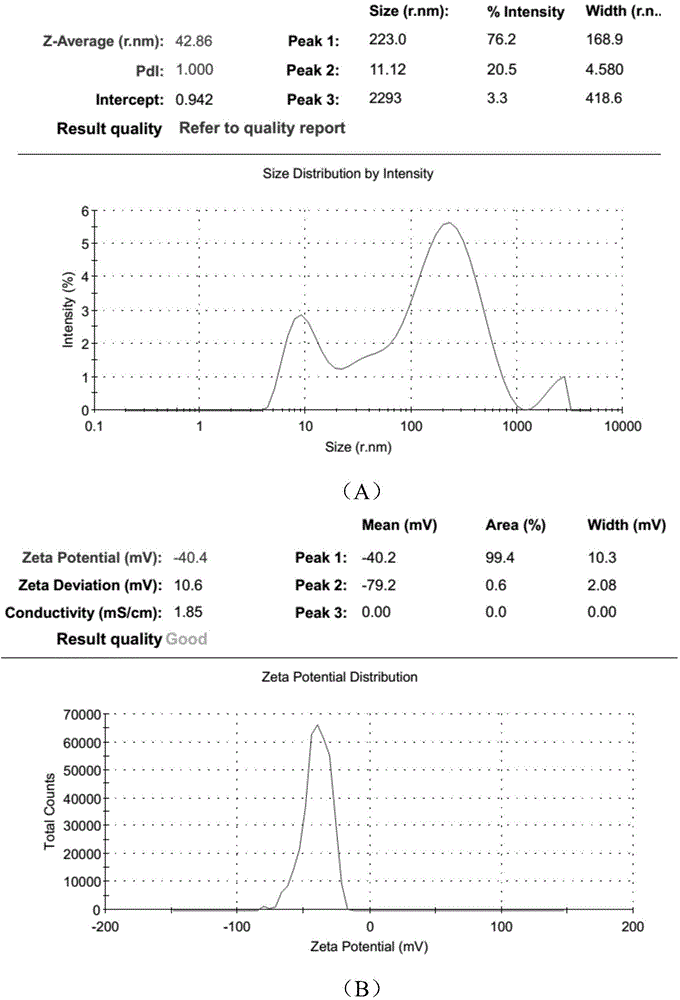

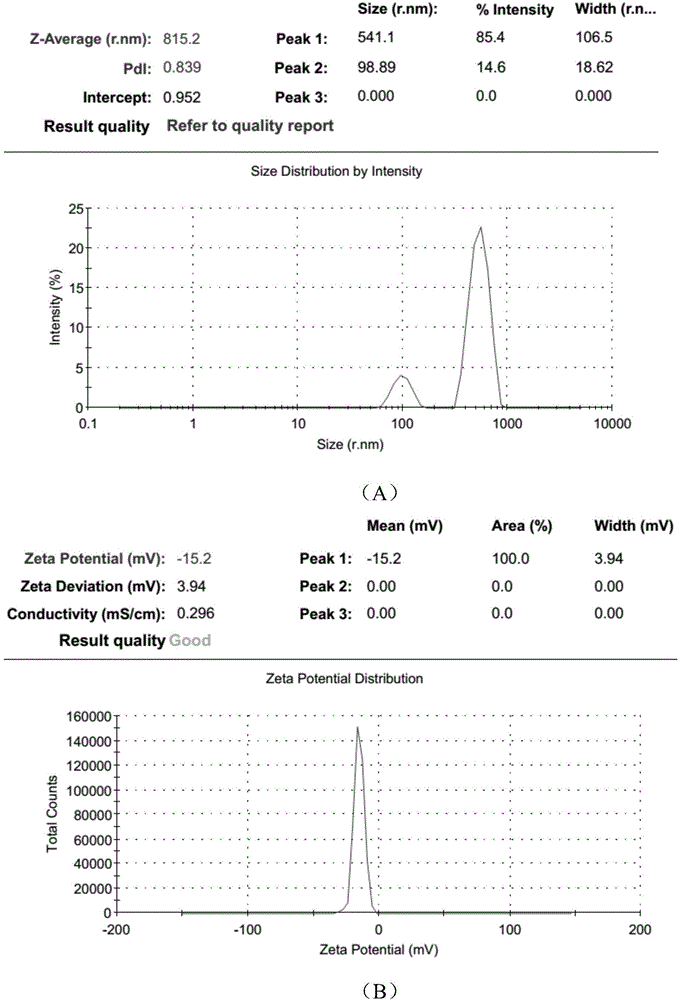

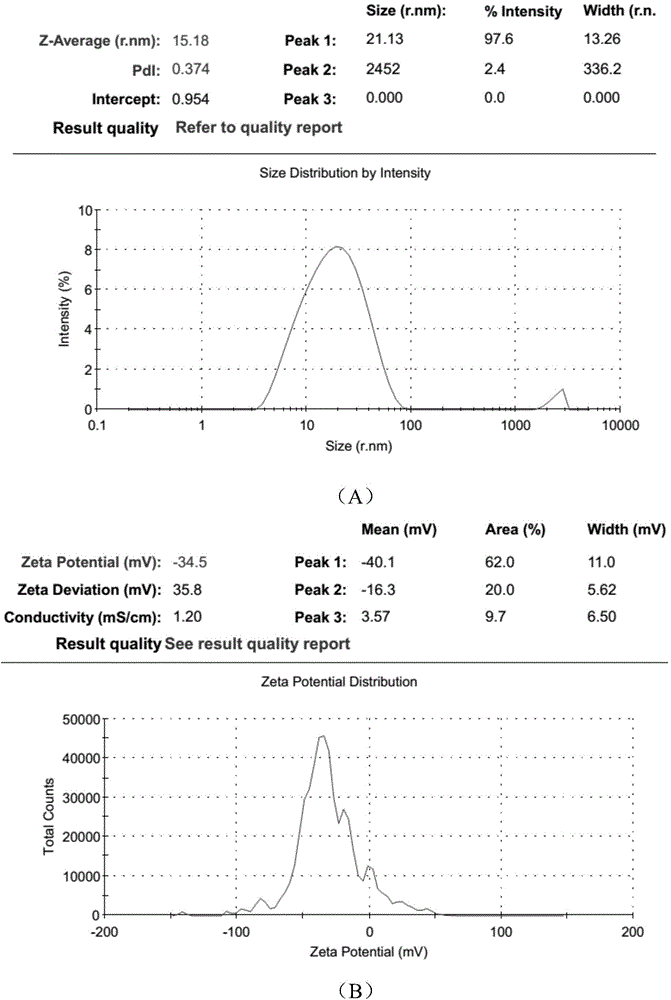

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com