Dry and wet combined digestion treatment method for livestock manure and straw

A technology for livestock manure and digestion treatment, which is applied in the directions of combined biological treatment, biological organic part treatment, and preparation of organic fertilizers, can solve the problems of large water consumption, difficulty in feeding and discharging materials, single raw materials, etc., and achieves a reduction in the total solid content. , to ensure normal operation and improve the effect of gas production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

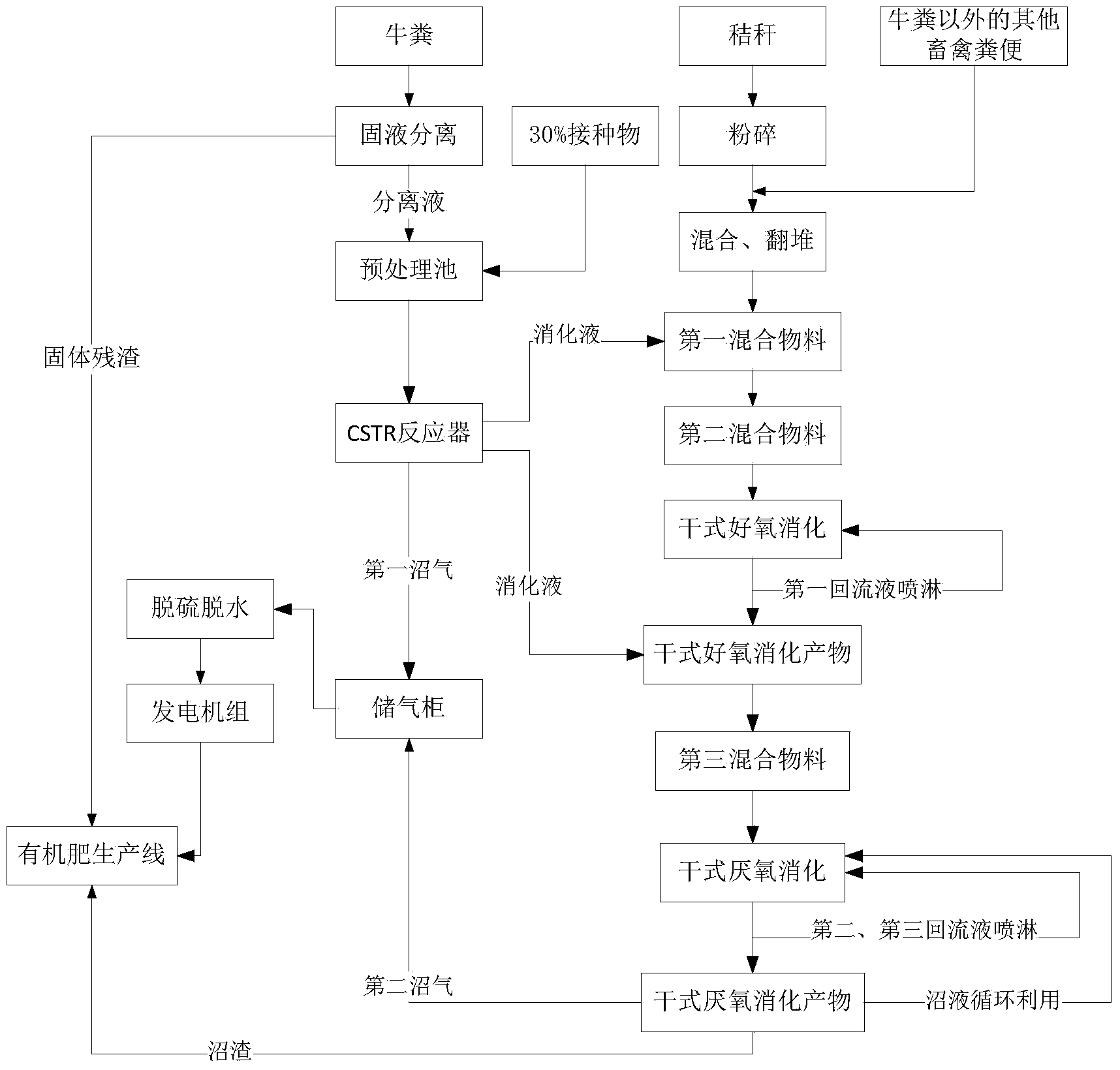

[0042] The method of dry-wet combined digestion of poultry manure and stalks in this embodiment is carried out according to the following steps:

[0043] 1) Solid-liquid separation:

[0044] The cow dung is separated from the solid and liquid by the spiral solid-liquid separation equipment, and finally the solid residue and the separation liquid with a moisture content of 40% to 50% are obtained, and the separation liquid flows into the pretreatment tank; the obtained solid residue is sent to the organic fertilizer production line, Made into organic fertilizer.

[0045] 2) Wet anaerobic digestion:

[0046]The wet anaerobic digestion device used in the present invention is a CSTR reactor, and a liquid sampling port is left in the middle of the CSTR reactor. Add 30% inoculum (biogas slurry produced after anaerobic fermentation of livestock and poultry manure) in the pretreatment tank and then stir, and then transfer the obtained mixture of the separated liquid and the inoculum...

Embodiment 2

[0061] The remainder of the method for treating poultry manure and stalks by combined dry-wet digestion in this embodiment is the same as in Embodiment 1, except that:

[0062] The C / N ratio of the first mixed material obtained in the above step 3) is 25:1.

[0063] In the above step 4), in the material preparation stage before the dry aerobic digestion, the water content of the second mixed material is 60%; during the dry aerobic digestion process, the oxygen supply and ventilation volume of the blast device is 3m 3 / min, the flow rate of the first leachate is 4m 3 / min, reflux mist spray once a day, 30min each time, ambient daily average temperature 10°C, aerobic digestion for 5 days to generate aerobic digestion products.

[0064] In the above step 4), in the material preparation stage before the dry anaerobic digestion, the water content of the third mixed material is 75%; during the dry anaerobic digestion process, the pressure in the dry digestion device is maintained a...

Embodiment 3

[0068] The remainder of the method for treating poultry manure and stalks by combined dry-wet digestion in this embodiment is the same as in Embodiment 1, except that:

[0069] The C / N ratio of the first mixed material obtained in the above step 3) is 20:1.

[0070] In the above step 4), in the material preparation stage before the dry aerobic digestion, the water content of the second mixed material is 55%; during the dry aerobic digestion process, the oxygen supply and ventilation volume of the blast device is 2m 3 / min, the flow rate of the first leachate is 2m 3 / min, reflux mist spray once a day, 20min each time, ambient daily average temperature 25°C, aerobic digestion for 3 days to generate aerobic digestion products.

[0071] In the above step 4), in the material preparation stage before the dry anaerobic digestion, the water content of the third mixed material is 70%; during the dry anaerobic digestion process, the pressure in the dry digestion device is maintained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com