Graphene-based nanometer zero-valent aluminum coating and preparation method thereof

A graphene-based, nano-zero-valent technology, used in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc. , The key role of graphene has not been maximized, and the best performance of graphene and other nanoparticles has not been exerted to achieve low cost, easy industrial mass production, and excellent anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

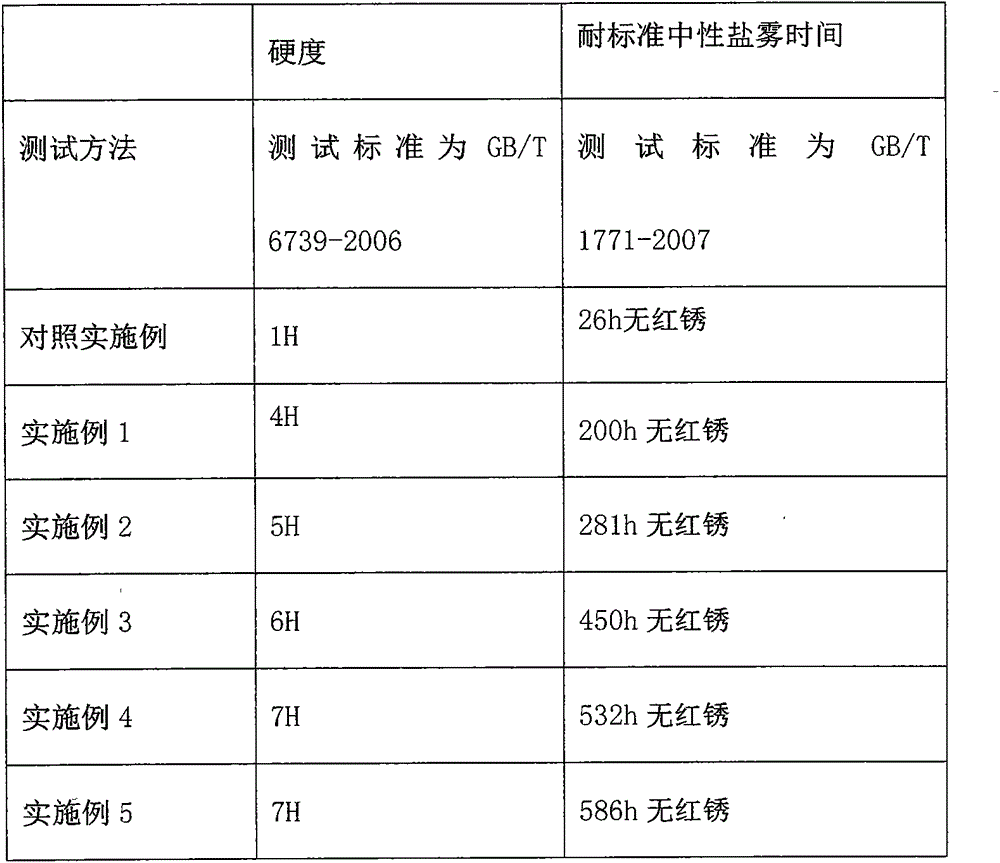

Embodiment 1

[0034]A graphene-based nano-zero-valent aluminum-based coating, each component is weighed in the following parts by weight:

[0035] 5 parts of graphene-based nano zero-valent aluminum,

[0036] 6 parts of graphene-based nano zero-valent zinc,

[0037] 3 parts of graphene-based nano-titanium dioxide,

[0038] 3 parts of graphene-based nano silicon dioxide,

[0039] 5 parts of graphene-based nano calcium carbonate,

[0040] Silicone epoxy resin 45 parts

[0041] 20 parts of polyphenylene sulfide resin,

[0042] 5 parts melamine formaldehyde resin

[0043] 25 parts of n-butanol

[0044] 20 parts ethanol

[0045] 1.0 parts of alkylphenol polyoxyethylene ether,

[0046] 0.8 part of polyhydroxy acid sodium salt,

[0047] 0.5 parts of methylcellulose,

[0048] 0.2 parts of methyl silicone oil,

[0049] 0.3 parts of dioctyl phthalate,

[0050] 0.3 part of polyether polyester modified organosiloxane,

[0051] Titanium dioxide 4 parts

[0053]...

Embodiment 2

[0062] A graphene-based nano-zero-valent aluminum-based coating, each component is weighed in the following parts by weight:

[0063] 8 parts of graphene-based nano zero-valent aluminum,

[0064] 6 parts of graphene-based nano zero-valent zinc,

[0065] 3 parts of graphene-based nano-titanium dioxide,

[0066] 3 parts of graphene-based nano silicon dioxide,

[0067] 5 parts of graphene-based nano calcium carbonate,

[0068] Silicone epoxy resin 45 parts

[0069] 20 parts of polyphenylene sulfide resin,

[0070] 5 parts urea-formaldehyde resin

[0071] 25 parts of n-butanol

[0072] 20 parts ethanol

[0073] 1.0 parts of alkylphenol polyoxyethylene ether,

[0074] 0.8 parts of sodium bisuccinate sulfonate,

[0075] 0.5 parts of hydroxyethyl cellulose,

[0076] 0.2 parts of tributyl phosphate,

[0077] 0.3 parts of dibutyl phthalate,

[0078] 0.3 parts of polydimethylsiloxane leveling agent,

[0079] 8 parts of paint,

[0080] 3 parts superfine talc powder

[0081...

Embodiment 3

[0089] A graphene-based nano-zero-valent aluminum-based coating, each component is weighed in the following parts by weight:

[0090] 10 parts of graphene-based nano-zero-valent aluminum,

[0091] 6 parts of graphene-based nano zero-valent zinc,

[0092] 3 parts of graphene-based nano-titanium dioxide,

[0093] 3 parts of graphene-based nano silicon dioxide,

[0094] 5 parts of graphene-based nano calcium carbonate,

[0095] Silicone epoxy resin 45 parts

[0096] 20 parts of polyphenylene sulfide resin,

[0097] 5 parts urea-formaldehyde resin

[0098] 25 parts of n-butanol

[0099] 20 parts ethanol

[0100] 1.0 parts of alkylphenol polyoxyethylene ether,

[0101] 0.8 parts of sodium bisuccinate sulfonate,

[0102] 0.5 parts of hydroxyethyl cellulose,

[0103] 0.2 parts of tributyl phosphate,

[0104] 0.3 parts of dibutyl phthalate,

[0105] 0.3 parts of polydimethylsiloxane leveling agent,

[0106] 8 parts of paint,

[0107] 0.3 parts of superfine talcum powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com