Method for separating kudinoside A and kudinoside D from Ilex kudingcha C.J.Tseng

A technology of Kudingcha holly and Kudingchai, which is applied in the field of saponins, can solve the problems of no clear specific implementation method, small differences in properties, difficult separation, etc. Great prospect and good economical applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

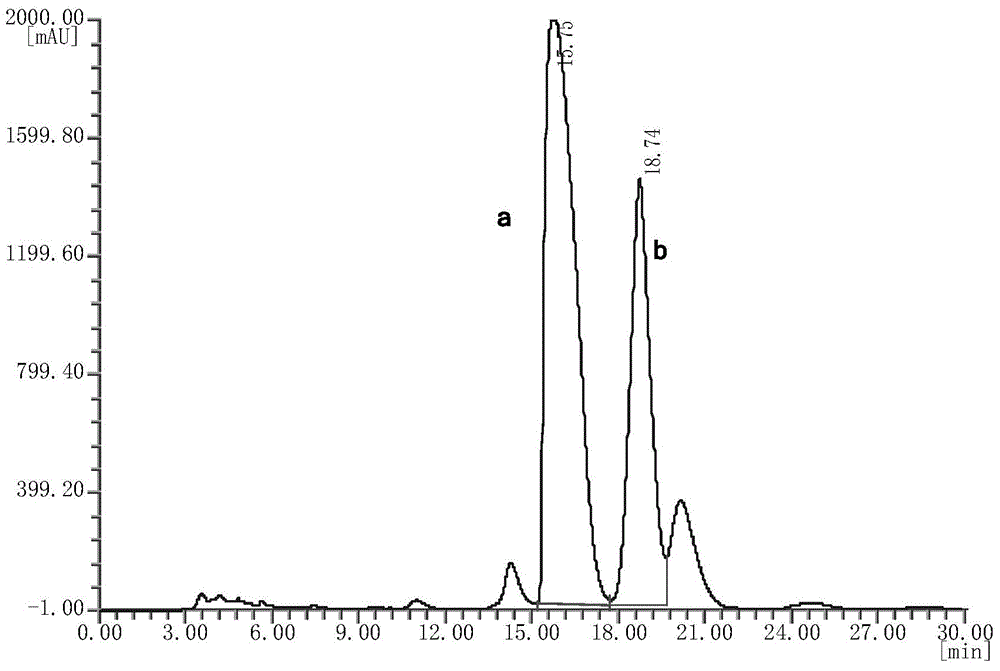

[0030] 1. Separation of Kubutin A and D

[0031] (1) Weigh 500 g of dried Kudingcha holly leaves, crush them through a No. 3 sieve, and extract by percolation with 20 times the amount of methanol (10 L). Recover methanol to obtain Kudingcha Dongqing extract 212g, add 300mL of distilled water to make a dispersion system. First extract with chloroform three times, each time 350mL, and then extract with water-saturated n-butanol three times, each time 350mL. Concentrate the n-butanol extract to a thick paste.

[0032] (2) the gained thick paste is absorbed with 214g macroporous resin, uses 860g macroporous resin as column chromatography filler, washes 6 column volumes with pure water earlier, then uses methanol-water gradient elution (30% → 60% →80%), each gradient eluent is 8-10 column volumes. After TLC analysis, the target compound was collected in the 60% methanol eluent, and the components containing the target compound were combined to recover the solution to obtain 24 g...

Embodiment 2

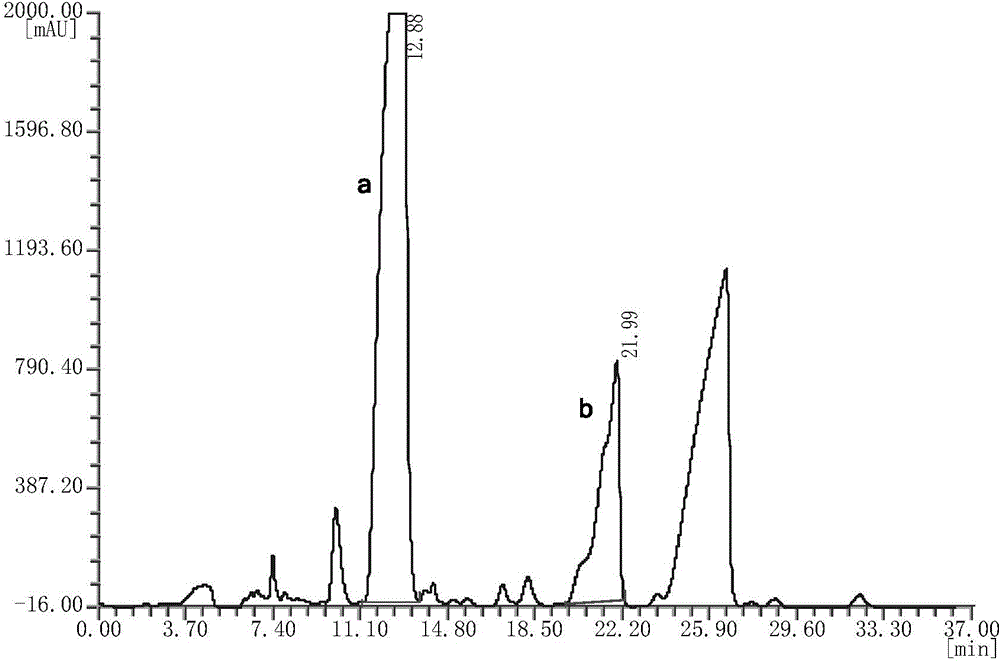

[0052] 1. Separation of Kubutin A and D

[0053] (1) Weigh 500 g of dried Kudingcha holly leaves, pulverize them through a No. 3 sieve, extract with 8 times the amount (4 L) of ethanol with a mass fraction of 75% under reflux, and extract twice, each time for 60 minutes. Recover the solvent to obtain 233g of Kudingcha Dongqing extract, add 350mL of distilled water to form a dispersion system, first extract three times with chloroform, 400mL each time, and then extract 3 times with water-saturated n-butanol, 400mL each time. Concentrate the n-butanol extract to a thick paste.

[0054] (2) 250g macroporous resin adsorption is mixed sample with gained thick paste, use 900g macroporous resin as filler, carry out column chromatography, elution 6 column volumes with pure water earlier, then use ethanol-water gradient elution ( 25% → 55% → 75%), each gradient elution solution is 8-10 column volumes. After TLC analysis, the target compound was collected in the 55% ethanol eluent, an...

Embodiment 3

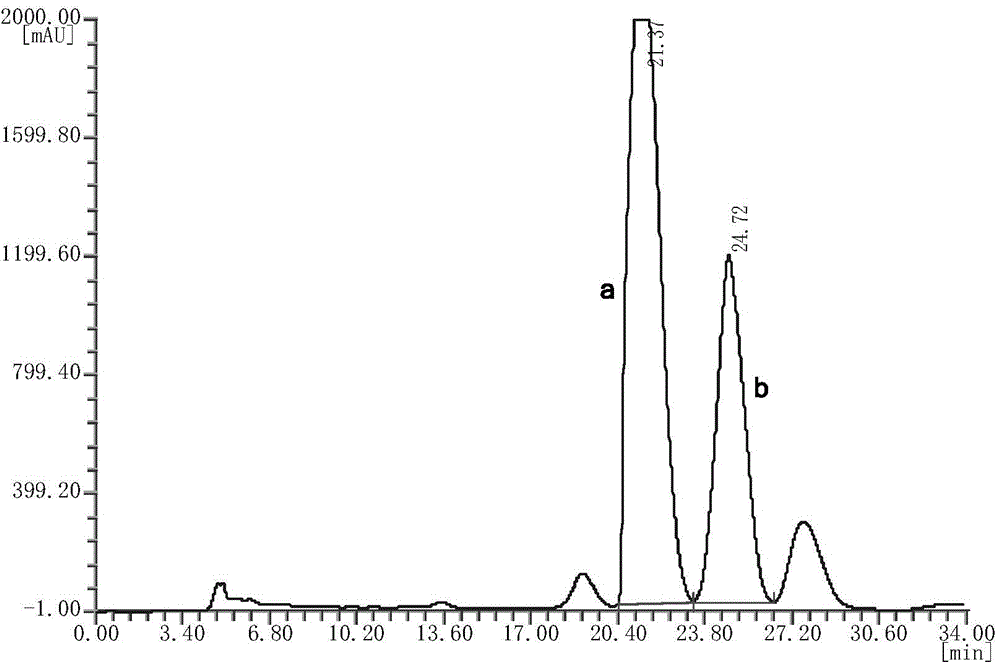

[0061] 1. Separation of Kubutin A and D

[0062] (1) Weigh 300 g of dried leaves of Ilex kudingcha, crush them through a No. 3 sieve, extract by percolation with 20 times the amount (6 L) of ethanol with a mass fraction of 80%, and recover the solvent to obtain 126 g of Ilex kudingcha extract. Add 200 mL of distilled water to form a dispersed system, first extract three times with chloroform, 250 mL each time, and then extract three times with saturated n-butanol, 250 mL each time. Concentrate the n-butanol extract to a thick paste.

[0063] (2) The obtained thick paste is adsorbed and mixed with 120g macroporous resin, and 480g of macroporous resin is used as a filler to carry out column chromatography, and eluted with pure water for 6 column volumes, and then ethanol-water gradient elution (25%→55%→75%), each gradient elution solution is 8-10 column volumes. After TLC analysis, the target compound was collected in the 55% ethanol eluent, and the components containing the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com