Preparation method of uridine diphosphate glucose

A technology of uridine diphosphate glucose and uridine diphosphate, which is applied in the field of preparation of uridine diphosphate glucose, and can solve problems such as difficult separation and aggravated separation process burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

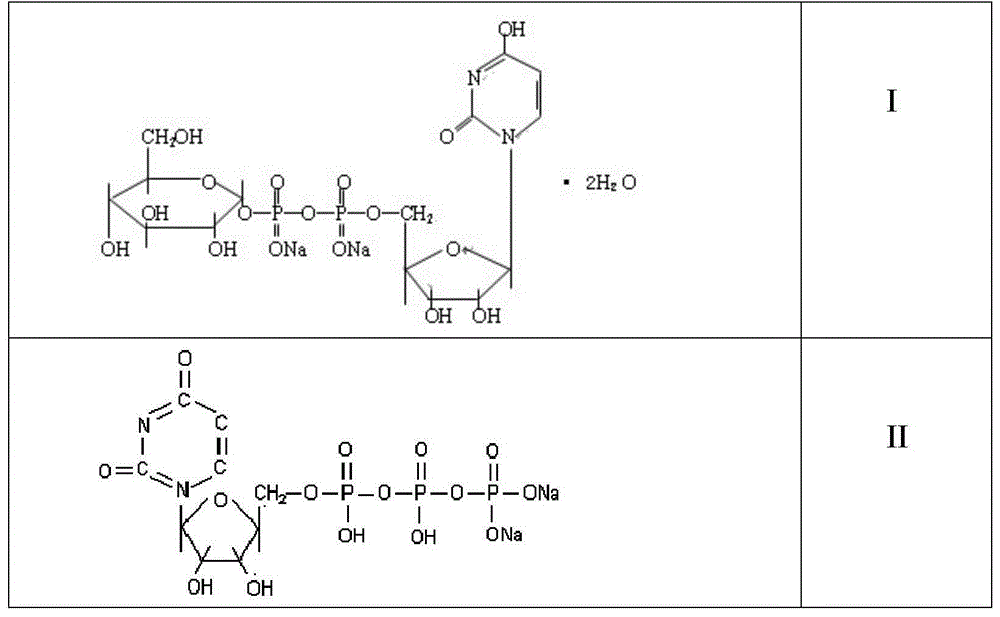

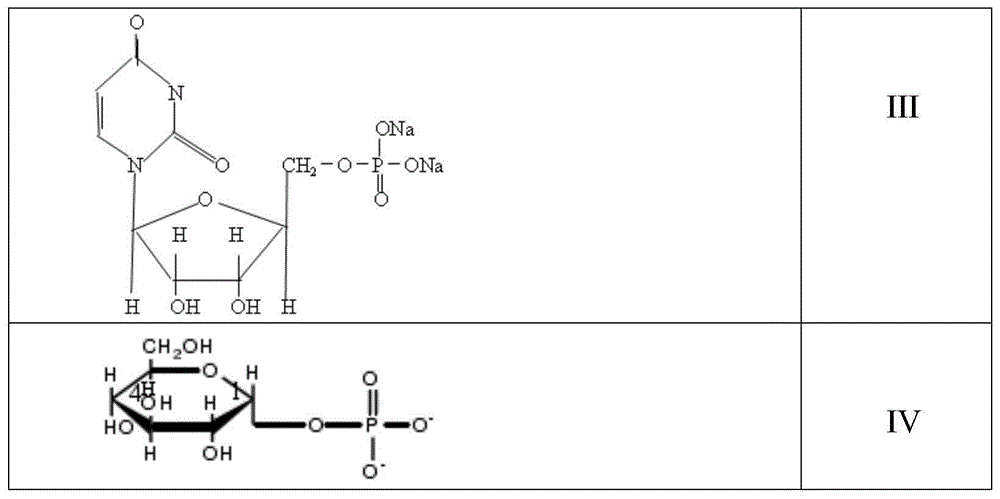

[0055] The method for preparing uridine diphosphate glucose (UDPG) comprises: in an in vitro (extracellular) reaction system, using uridine triphosphate (UTP) or its salt (such as sodium salt) and maltodextrin as substrates , add inorganic ions, dTT and Tris, and use uridine diphosphate glucose pyrophosphorylase and maltodextrin phosphorylase recombinantly expressed in Escherichia coli as catalysts to produce uridine diphosphate glucose through biotransformation.

[0056] In the preparation process of UDPG, the UDPG pyrophosphorylase and maltodextrin phosphorylase added in the reaction system can be derived from animals, plants, microorganisms, etc., and the source is not particularly limited, and enzymes from any source can be used . With the development of genetic engineering technology, the use of Escherichia coli to recombine and express the target protein is simpler and feasible than animal and plant extraction. Escherichia coli cells expressing UDPG pyrophosphorylase an...

Embodiment 1

[0077] Embodiment 1, press yeast to prepare UDPG

[0078] (1) Pretreatment of waste beer yeast

[0079] Take 20 kg of fresh waste beer yeast from the brewery, press filter with plate and frame, blow dry, and collect 2.5 kg of filter cake.

[0080] (2) Pressed yeast permeability treatment

[0081] According to the amount of 5ml of xylene added per kilogram of filter cake, 12.5ml of xylene was added to 2.5kg of yeast filter cake, dispersed and mixed at a high speed, and stored at -20°C.

Embodiment 2

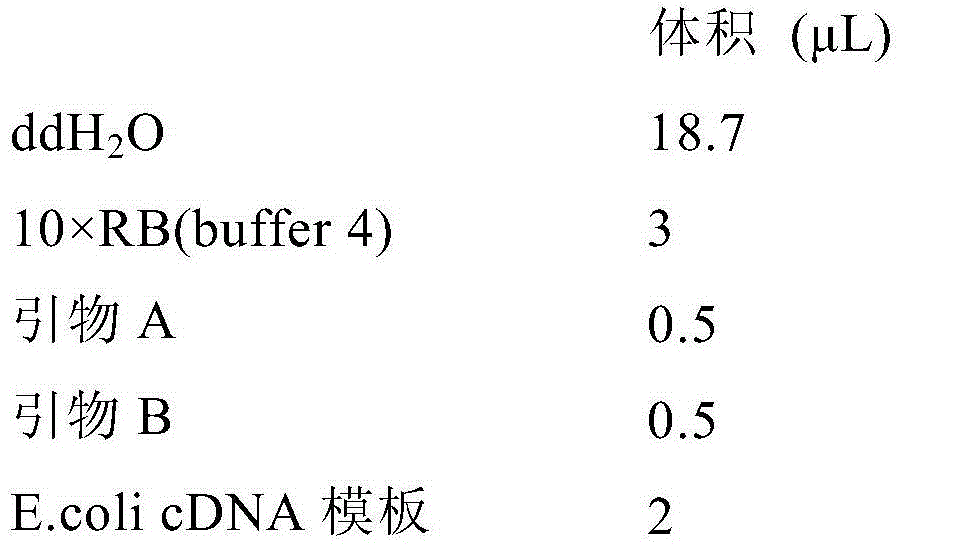

[0082] The preparation of embodiment 2, UTP

[0083] UMP·Na is prepared in a reactor with a capacity of 20L 2 300 grams, 10L of reaction solution consisting of 150 grams of glucose, 150 grams of potassium dihydrogen phosphate, 25 grams of magnesium sulfate, and 1.8 kg of pressed yeast, adjust the pH to 7.0 with sodium hydroxide, and react at 37°C for 8 hours, then add hydrochloric acid to adjust PH=2.5, after resting for 30 minutes, high-speed refrigerated centrifugation (12000rpm, 30min), got UTP Na 3 358 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com