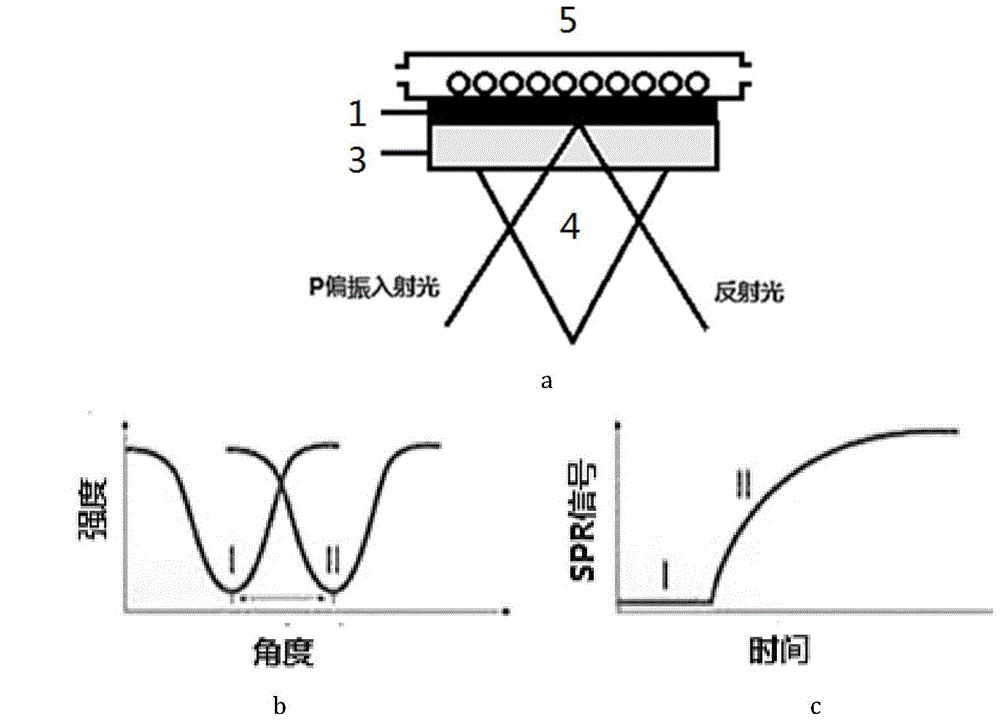

Chip for SPR bioreactor as well as preparation method and application of chip

A biosensor and chip technology, applied in the field of optical sensors, can solve the problems of complex preparation process and non-universal application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

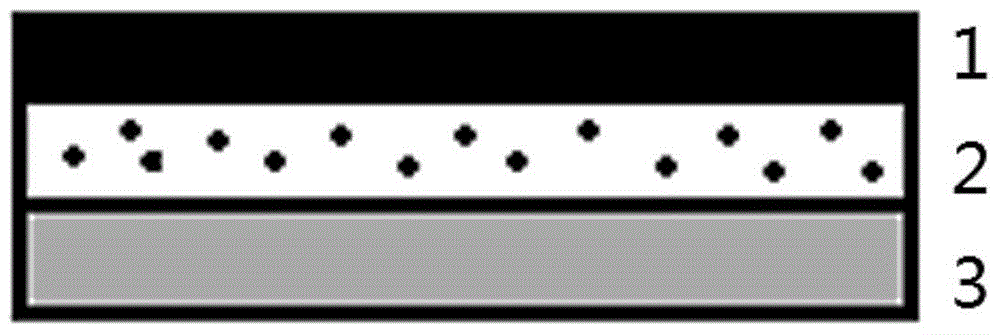

[0033] This embodiment includes the following steps:

[0034] 1) Preparation of graphene / polymer composite: Dissolve 10 mg of graphene with a sheet diameter of less than 200 nm in 10 mL of N, N-dimethylformamide solution for 30 min and ultrasonically disperse it with 1 g of polyethylmethacrylate Esters (Mw=100000) in 20mL N, N-dimethylformamide were mixed evenly.

[0035] 2) Take a certain amount of the prepared graphene / polymer composite and drop it on the glass substrate used to prepare the SPR sensor chip, and spin coat it through a coater at a speed of 6000r / min for 10s. Afterwards, put the glass slide in a vacuum oven and dry it at 100°C for 6 hours to completely evaporate the solvent.

[0036] 3) The chip can be obtained by evaporating a layer of gold film with a thickness of 40 nm through a magnetron sputtering evaporator.

[0037] Graphene in the above operation can also be replaced by graphene oxide.

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] 1) Preparation of graphene oxide / polymer composite:

[0041]1.1) 50mg of graphene oxide with sheet diameter less than 100nm, 76mg of 1‐(3‐dimethylaminopropyl)‐3‐ethylcarbodiimide hydrochloride, 125mg of N‐hydroxysuccinimide, 21mg2,3 ‐Dibromopropionamide was mixed in 20 mL of aqueous solution for 15 minutes to covalently link 2,3‐dibromopropionamide to graphene oxide.

[0042] 1.2) Take 50mL of a 1:1 mixture of water and methanol into a 250mL single-necked round bottom flask, add 5g of methyl methacrylate monomer, 50mg of CuCl 2 , 120mg 2,2-bipyridyl, 70mg ascorbic acid, mix well.

[0043] 1.3) Add the graphene oxide mixed solution to the solution system, stir at room temperature and react under nitrogen protection for 24 hours. After the gray-white viscous substance appears in the system, filter it. After cleaning the white viscous substance with deionized water several times, vacuum oven Dry at 60°C.

[0044] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com