Organosilicon modified polyester coiled material finish paint and preparation method thereof

A modified polyester and silicone technology, applied in polyester coatings, coatings, etc., can solve the problems of modified polyester such as flexibility and adhesion decline, and achieve high fullness, good workability, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

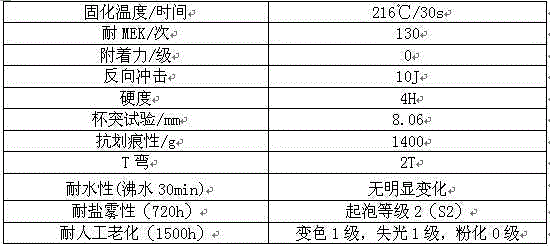

Embodiment 1

[0020] A kind of organosilicon modified polyester coil topcoat described in the present embodiment, it is made of containing weight ratio 500g organosilicon modified polyester resin, 90g amino resin, 30g phthalocyanine blue, 80g titanium dioxide, 1g organic yellow, 90g Precipitated barium sulfate, 90g precipitated barium sulfate, 4g polydimethylsiloxane, copolymer of low molecular weight unsaturated polycarboxylic acid polymer and polysiloxane, 3g 2-hydroxy-4-n-octyloxybenzophenone , 5g dodecylbenzenesulfonic acid, 3g polyether modified polydimethylsiloxane or polyester modified polydimethylsiloxane, 3g isocyanate modified acrylate or polyether polyester modified silicone and 100g xylene; among them, silicone modified polyester resin is composed of 10g isophthalic acid, 8g adipic acid, 6g1,4-cyclohexanedicarboxylic acid, 8g neopentyl glycol, 7g ethyl butyl propylene glycol, 7g of 2,2,4-trimethyl-1,3-pentanediol, 0.08g of tin catalyst, 20g of organosilicon intermediate, 2.5g of...

Embodiment 2

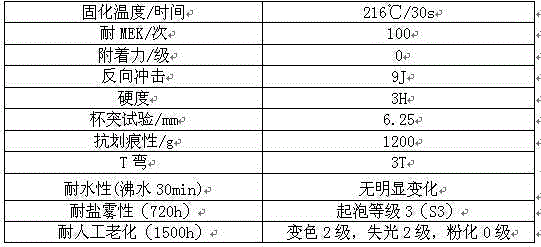

[0027] A kind of organosilicon-modified polyester coil topcoat described in this embodiment, it is made of organosilicon-modified polyester resin, 90g amino resin, 30g phthalocyanine blue, 80g titanium dioxide, 1g organic yellow, 90g precipitated barium sulfate, 4g polydimethylsiloxane, copolymer of low molecular weight unsaturated polycarboxylic acid polymer and polysiloxane, 3g2-hydroxyl-4-n-octyloxybenzophenone, 5g dodeca Alkylbenzenesulfonic acid, 3g polyether-modified polydimethylsiloxane or polyester-modified polydimethylsiloxane, 3g isocyanate-modified acrylate or polyether-modified polyester silicone and 100g butyl ether Composition; Among them, the silicone modified polyester resin is composed of 12g monoacid, 10g isophthalic acid, 18g terephthalic acid, 4.5g adipic acid, 20.5g methyl propylene glycol, 2.1g trimethylol methyl propane, 2g Refluxing xylene, 2.5g of trimellitic anhydride, 30g of No. 100 aromatic hydrocarbon solvent and 6g of butanol.

[0028] A kind of ...

Embodiment 3

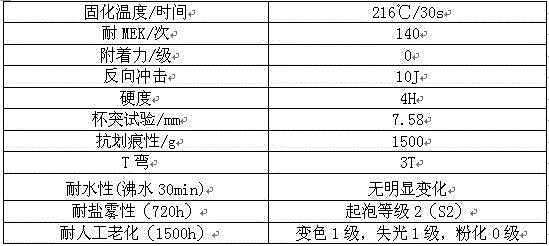

[0034] A kind of organosilicon-modified polyester coil topcoat described in this embodiment, it is made of organosilicon-modified polyester resin, 120g amino resin, 50g titanium dioxide, 6g carbon black, 1g organic yellow, 90g by weight ratio 500g Precipitated barium sulfate, 4g polydimethylsiloxane, copolymer of low molecular weight unsaturated polycarboxylic acid polymer and polysiloxane, 3g 2-hydroxy-4-n-octyloxybenzophenone, 5g dinonyl Naphthalenesulfonic acid, 3g polyether modified polydimethylsiloxane or polyester modified polydimethylsiloxane, 3g isocyanate modified acrylate or polyether polyester modified silicone and 100g aromatic hydrocarbon; , Silicone modified polyester resin is composed of 10g isophthalic acid, 8g adipic acid, 6g1,4-cyclohexanedicarboxylic acid, 8g neopentyl glycol, 7g ethyl butyl propanediol, 7g2,2,4-tri Methyl-1,3-pentanediol, 0.08g tin catalyst, 20g organosilicon intermediate, 2.5g refluxing xylene, 2.5g trimellitic anhydride, 25g No. 100 aroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com