Nano aluminium nitride composite chromium plating solution and electroplating method

A nano-aluminum nitride and chromium electroplating technology, which is applied in the direction of electrolytic coatings and coatings, can solve the problems of low hardness of the coating, restrictions on the large-scale application of Ni electroplating, and difficulty in realizing nano-composite electroplating, and achieve the effect of improving the quality of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (1) Preparation of nano-dispersion. Using self-made nano-aluminum nitride after impurity removal, the preparation method of nano-aluminum nitride and the specific process of impurity removal have been described above, and will not be repeated here. Add the fatty alkyl methyl halide and alkylbenzene sulfonate into the three-necked flask to dissolve and then stir with a mixer at low speed for several minutes. Then, transfer it to a large beaker and install the GR-I shear disperser of Chengdu Xindu Yongtong Machinery Factory, add the powder of nano-aluminum nitride into the three-necked flask, and adjust the speed of the shear disperser to 300~ 500rpm, the shear dispersion time is 5-10min, then adjust the rotational speed to 1500-2000rpm, and the shear dispersion time is 10-15min to obtain the nano slurry. The average particle size of the nano-dispersion was tested by a Mastersizer 2000 laser particle size analyzer from Malvern.

[0033] (2) Weigh the mass of other raw m...

Embodiment 1

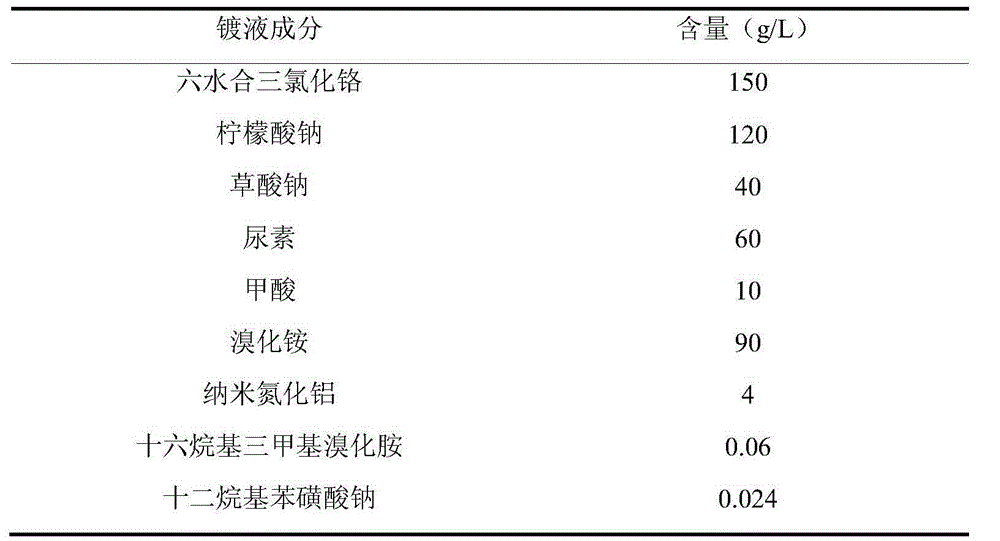

[0039] The formula of nano-aluminum nitride composite chromium electroplating solution is as follows:

[0040]

[0041] In the nano-dispersion liquid preparation, the rotating speed of low-speed shear dispersion is 300rpm, and the time of low-speed shear dispersion is 5min; the rotational speed of high-speed shear dispersion is 1500rpm, and the time of high-speed shear dispersion is 10min; the ultrasonic dispersion power is 600W, The time of ultrasonic dispersion is 6min, and the average particle size of carbon nanometer in the prepared dispersion is 20nm; the plating process conditions: the pulse width of single pulse square wave current is 1ms, the duty ratio is 30%, and the average current density is 4A / dm 2 ; The pH is 2.5, the temperature is 25°C, and the electroplating time is 120min.

Embodiment 2

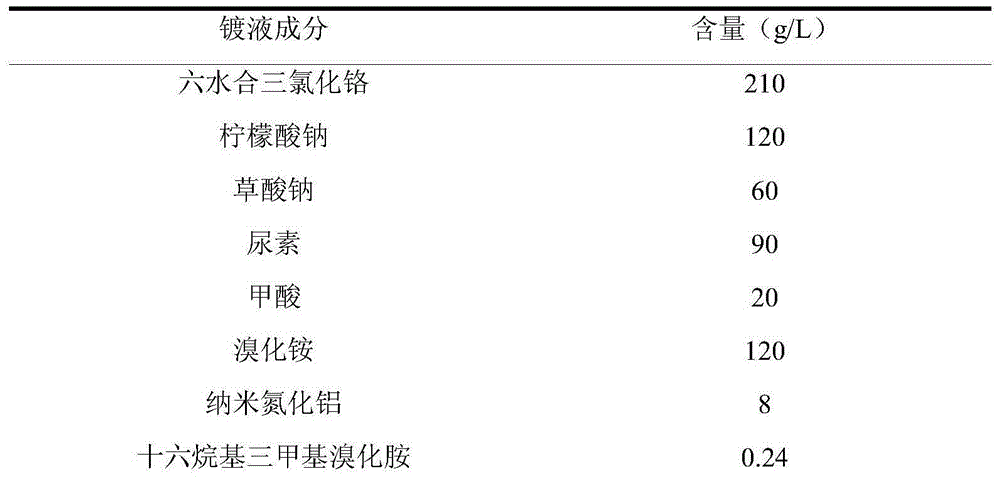

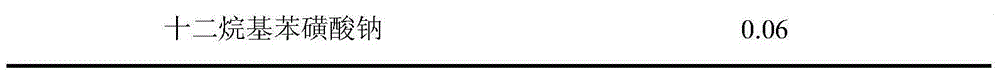

[0043] The formula of nano-aluminum nitride composite chromium electroplating solution is as follows:

[0044]

[0045]

[0046] In the nano-dispersion liquid preparation, the rotating speed of low-speed shear dispersion is 500rpm, and the time of low-speed shear dispersion is 10min; the rotational speed of high-speed shear dispersion is 2000rpm, and the time of high-speed shear dispersion is 15min; the ultrasonic dispersion power is 1000W, The time of ultrasonic dispersion is 3min, and the average particle size of carbon nanoparticles in the prepared dispersion is 30nm; the plating process conditions: the pulse width of single pulse square wave current is 1ms, the duty cycle is 25%, and the average current density is 5A / dm 2 ; The pH is 3, the temperature is 30°C, and the electroplating time is 100min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com