Foam transition-metal solid (gas) phosphated self-support hydrogen evolution electrode and preparation method thereof

A foam metal, transition metal technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the preparation process and assembly steps that hinder the large-scale production and practical application of phosphide hydrogen evolution electrodes, high toxicity and flammability, etc. problems, to achieve the effect of strong designability, variety, and adjustable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

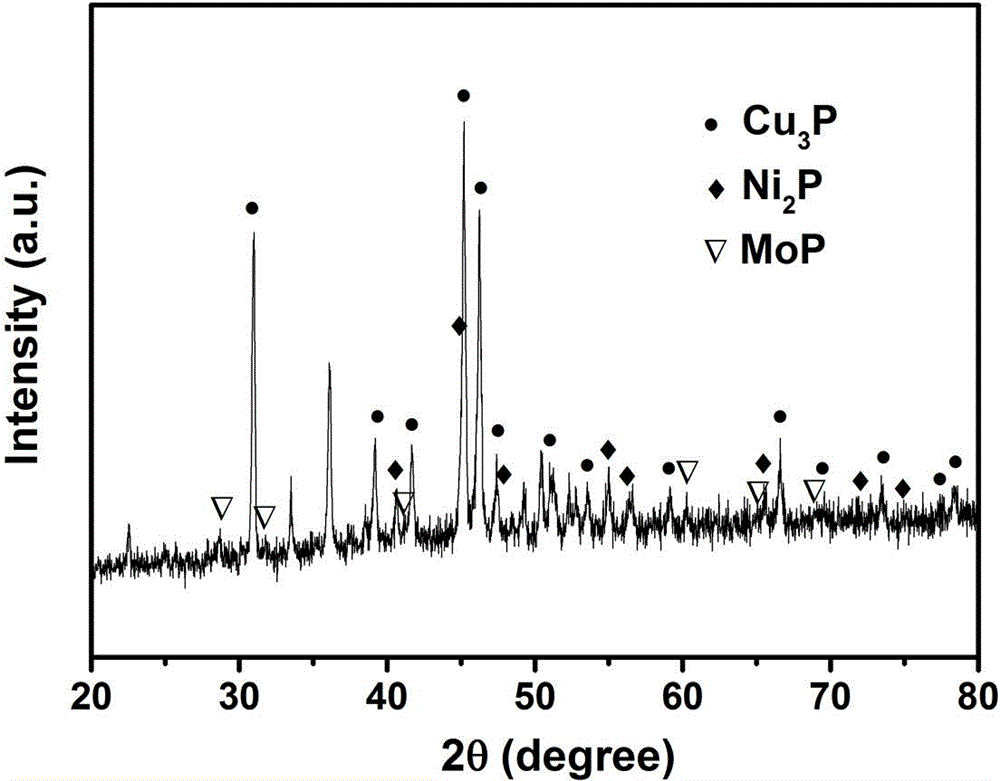

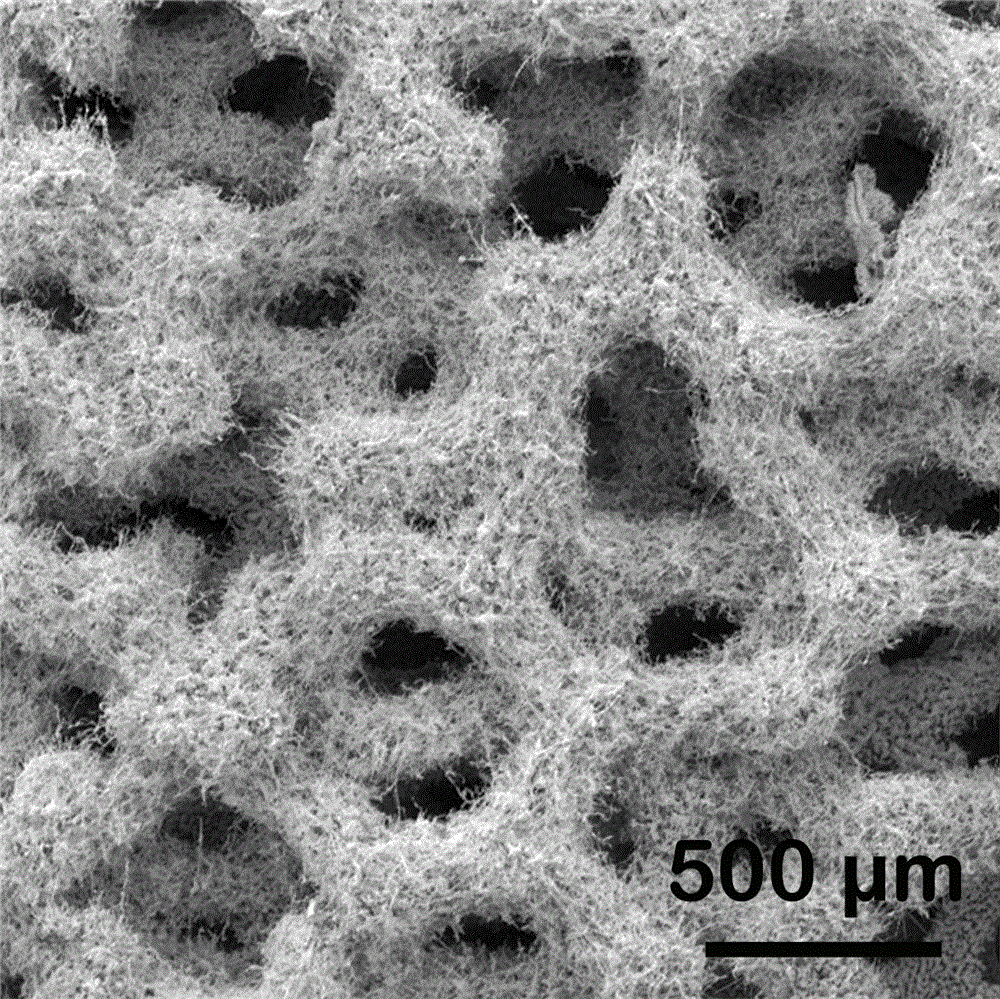

[0029] A solid (gas) state phosphating self-supporting hydrogen evolution electrode after electrochemically depositing a metal nickel-molybdenum alloy layer on the surface of foamed copper and a preparation method thereof, according to the following steps:

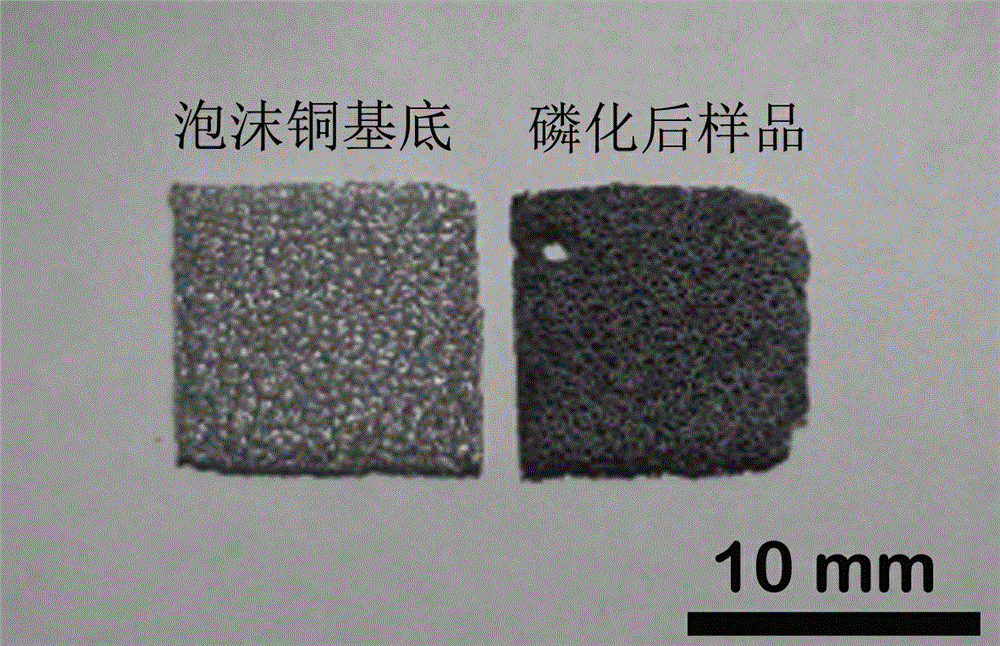

[0030] a. Foam copper (100ppi, see attached figure 1 ) soaked in 20wt.% hydrochloric acid solution and ultrasonically cleaned for 5 minutes to remove the surface oxide layer to expose the fresh metal surface, and then cleaned to neutral with ultrapure water;

[0031] b. Use the copper foam treated in step a as the cathode, and put nickel sulfate (5.26 g / L), sodium molybdate (6.18 g / L), trisodium citrate (29.41 g / L), ammonium citrate (22.61 g / L) and thiourea (7.61 g / L) mixed plating solution, with carbon rod as the anode, the current density is 2mA / cm 2 , the electrodeposition time is 60min, and an electrodeposited nickel-molybdenum alloy layer is obtained on the surface of the copper foam cathode;

[0032] c. Clean the f...

Embodiment 2

[0037] A foamed copper solid (gas) state phosphating self-supporting hydrogen evolution electrode and its preparation method are carried out according to the following steps,

[0038] a. Soak foam copper (100ppi) in 20wt.% hydrochloric acid solution and ultrasonically clean it for 5 minutes to remove the surface oxide layer to expose the fresh metal surface, and then clean it with ultrapure water until neutral;

[0039] b. Suspend the copper foam processed in step a in the ceramic boat, and sprinkle the red phosphorus powder on the bottom of the ceramic boat as the phosphorus source, and the mass ratio of the phosphorus source to the metal source is 0.7;

[0040] c. Put the ceramic boat in which the copper foam sample and red phosphorus are placed in step b into the middle of the tubular atmosphere furnace cavity, feed argon as a protective atmosphere, and ventilate for 30 minutes to remove the residual air;

[0041] d. To set the phosphating process parameters, first raise th...

Embodiment 3

[0043] A self-supporting hydrogen evolution electrode after nickel foam solid (gas) state phosphating and its preparation method are carried out according to the following steps,

[0044] a. Soak nickel foam (120ppi) in 20wt.% hydrochloric acid solution and ultrasonically clean it for 5 minutes to remove the surface oxide layer to expose the fresh metal surface, and then clean it with ultrapure water until neutral;

[0045] b. Suspend the nickel foam processed in step a in the ceramic boat, and sprinkle the red phosphorus powder on the bottom of the ceramic boat as the phosphorus source, and the mass ratio of the phosphorus source to the metal source is 0.7;

[0046] c. Put the ceramic boat in which the nickel foam sample and red phosphorus are placed in the step b into the middle of the tubular atmosphere furnace cavity, feed argon as a protective atmosphere, and ventilate for 30 minutes to remove the residual air;

[0047] d. To set the phosphating process and parameters, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com